Mineral-organic composite soil conditioner and preparation method thereof

A technology of soil conditioner and mineral powder, which is applied in the fields of agriculture and environmental protection. It can solve the problems of large environmental impact, high input cost, and high requirements for equipment and equipment, and achieve the effect of soil improvement, low cost, and no secondary pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

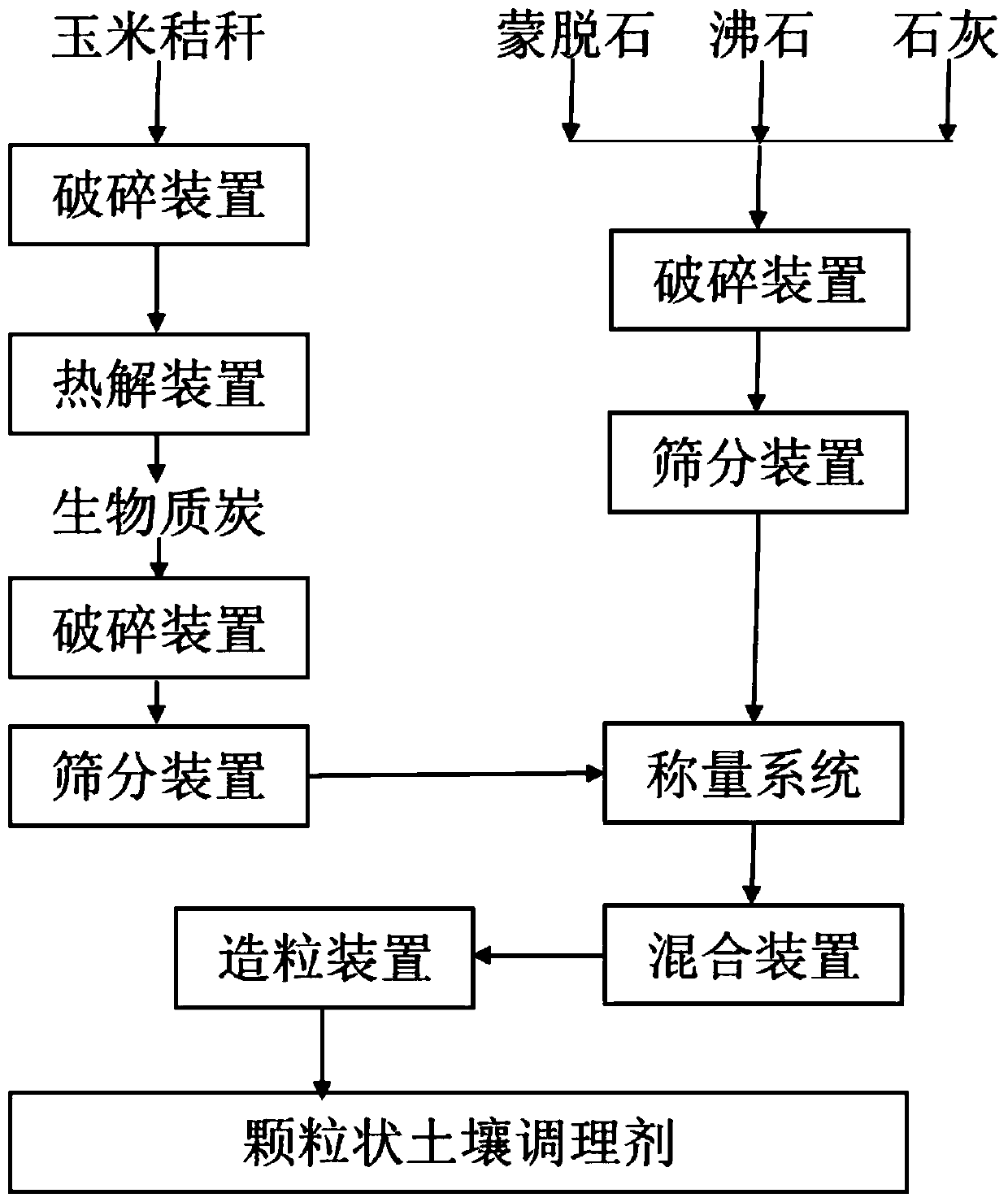

Method used

Image

Examples

Embodiment 1

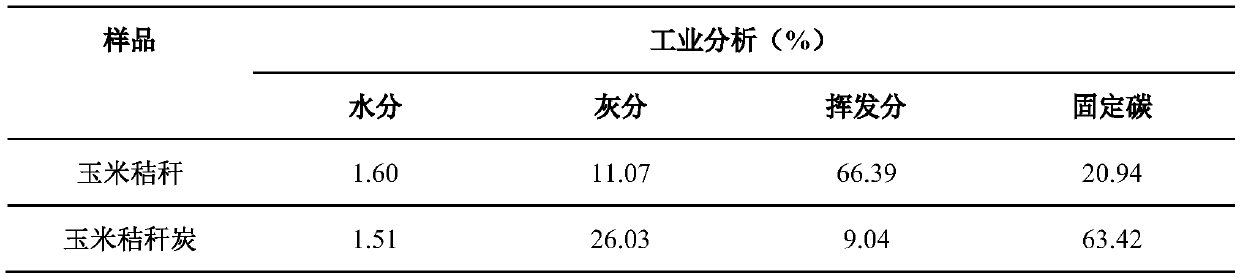

[0029] Use corn stalks as biomass raw materials, cut the stalks into small pieces with a length of 5-20cm and a width of 0.5-5cm, put them into a pyrolysis furnace for pyrolysis, the heating rate is 10-20°C / min, and the pyrolysis temperature is 500 -600°C, the pyrolysis time is 40-60min, and the generated biochar is crushed and sieved (100 mesh) to make a biochar powder sample. Industrial analysis of corn stalks and corn stalk charcoal (see Table 1) shows that after pyrolysis, the moisture content of corn stalks decreases, the ash content increases, the volatile matter decreases significantly, and the fixed carbon content increases significantly.

[0030] Table 1 Industrial analysis of corn stalks and the resulting corn stalk charcoal

[0031]

Embodiment 2

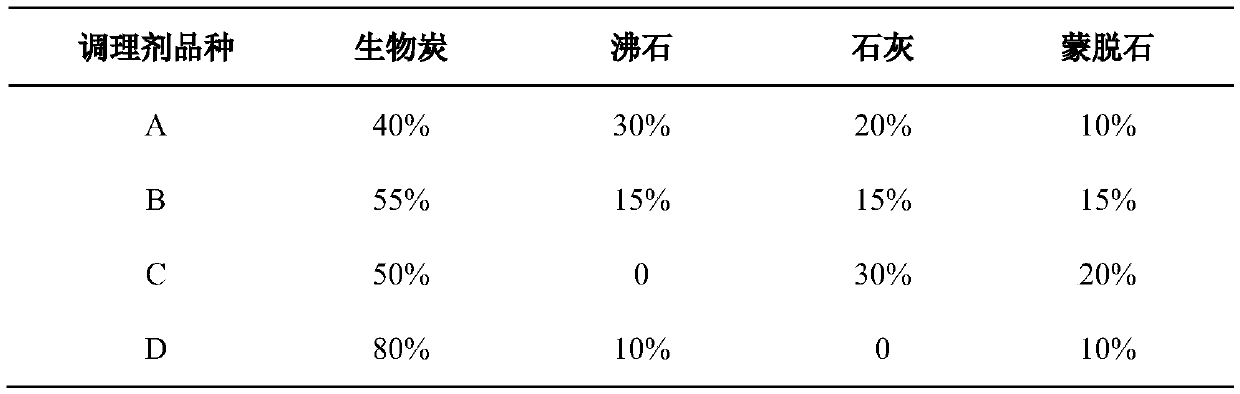

[0033] Biochar, lime, zeolite, and montmorillonite were used as raw materials, crushed and sieved, mixed evenly according to different mass ratios, and compounded into four different soil conditioners, as shown in Table 2, respectively A, B, C , D stands for. Select the surface soil of a polluted farmland (the soil pH value is 5.71, the available cadmium content is 0.92 mg / kg, and the available lead content is 29.1 mg / kg), and it is naturally air-dried in a cool indoor place. 100 mesh sieve. Accurately weigh 50g of soil and place it in a beaker, fully mix the conditioners of different formulations with the soil according to a certain addition ratio (0.5%, 1%, 3%, 5%), and repeat each treatment 3 times, with blank As a control, a certain amount of deionized water was added to make the soil water content reach 60% of the maximum water holding capacity in the field, and it was cultivated indoors (above 20° C.) with ventilation, and analyzed and measured after 30 days. Water was...

Embodiment 3

[0043]Select the soil conditioner prepared according to 40% biochar, 30% zeolite, 10% montmorillonite, 20% lime formula to detect the heavy metal content. The screening value in the Standard for Soil Pollution Risk Control of Agricultural Land (Trial) (GB 15618-2018) (5.5<pH≤6.5) can be used for soil remediation and improvement.

[0044] Heavy metal content (mg / kg) in table 6 soil conditioner

[0045]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com