Oxygen generator

An oxygen generator and oxygen technology, which is applied in the field of oxygen generators, can solve the problems of entering and affecting the long-term use of equipment, and achieve good adsorption effects, good drying and impurity removal effects, and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

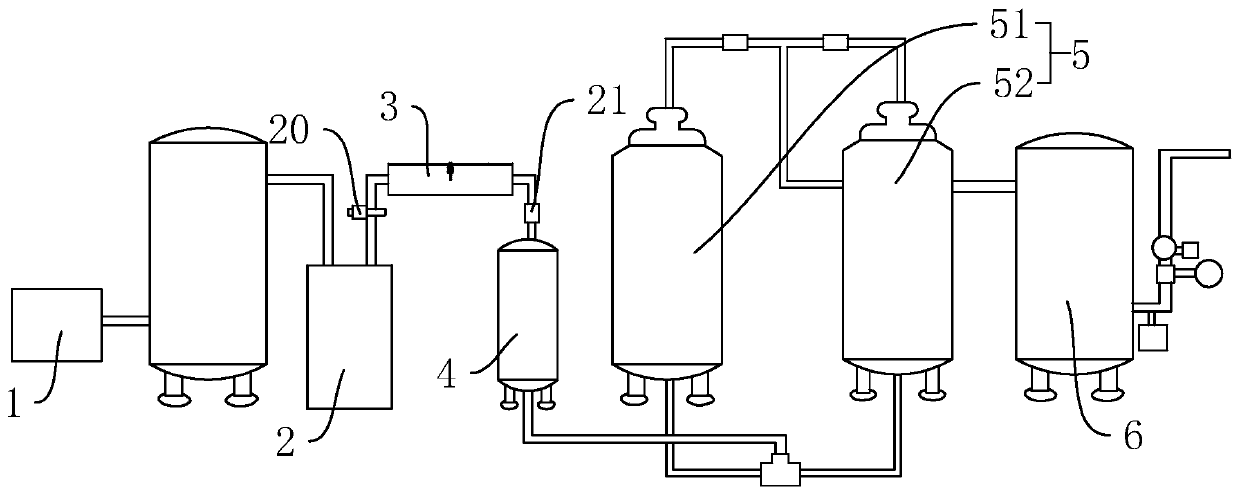

[0045] an oxygen generator such as figure 1 As shown, it includes an air compressor 1, a cold dryer 2, a filter device 3, an oil remover 4, an adsorption system 5, an oxygen buffer 6 and a controller (not shown), the air compressor 1, the cold dryer 2, The filtering device 3, degreaser 4, adsorption system 5 and oxygen buffer 6 are connected in sequence through pipelines. The adsorption system 5 includes a left adsorption tower 51 and a right adsorption tower 52. The left adsorption tower 51 and the right adsorption tower 52 are connected to the two outlets of the three-way valve through pipelines, and the inlet of the three-way solenoid valve is connected to the degreaser 4 through pipelines. export. The outlets of the left adsorption tower 51 and the right adsorption tower 52 are all connected to the oxygen buffer 6, and a check valve is connected between the left adsorption tower 51, the right adsorption tower 52 and the oxygen buffer 6, and the check valve makes the left ...

Embodiment 2

[0055] A kind of oxygen generator, the difference with embodiment one is, as Figure 6 As shown, a tank body 14 is connected between the cold dryer 2 and the filter device 3 through a conduit, the tank body 14 is set lower than the drain of the cold dryer 2, and the drain of the cold dryer 2 is connected to the The tank body 14 , the conduit connecting the tank body 14 with the filter device 3 is connected to the top of the tank body 14 .

[0056] Such as Figure 7 As shown, the bottom of the tank body 14 is communicated with a drain valve 16 . The outer wall of the tank body 14 is connected with a liquid level gauge 17 along the vertical direction. The liquid level gauge 17 is used to display the state of the water level in the tank body 14 .

[0057] Such as Figure 6 , Figure 8 As shown, the conduit connecting the tank body 14 with the cold dryer 2 is close to the bottom of the tank body 14 and penetrates into the tank body 14 to form a nozzle 18. The nozzle 18 is set ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com