Covalent organic framework material loaded Pd catalyst and preparation method and application thereof

A covalent organic framework and catalyst technology, applied in the preparation of organic compounds, organic compound/hydride/coordination complex catalysts, organic chemistry, etc., can solve complex organic ligand preparation, unstable catalyst repeatability, reaction Harsh conditions and other problems, to achieve the effect of easy recycling and reuse, wide application range of substrates, and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

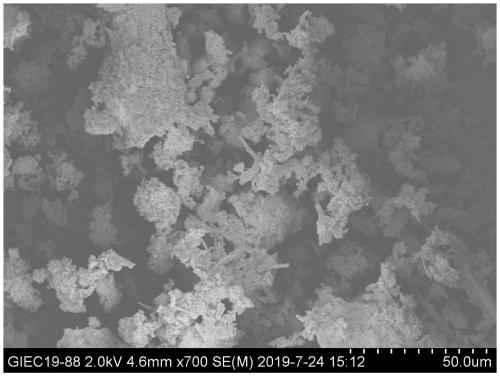

[0033] A kind of covalent organic framework material supports Pd catalyst, and its preparation method comprises the following steps:

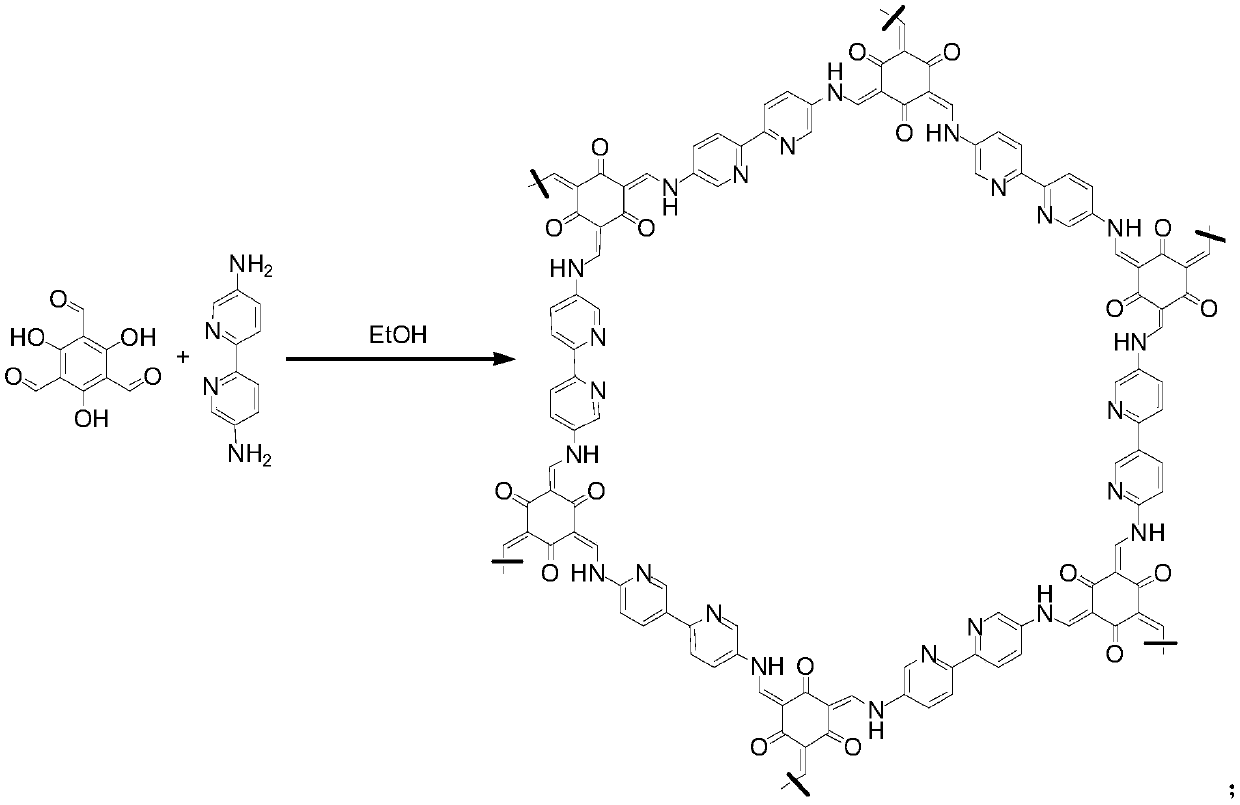

[0034] 1) Mix 2.3mmol of 2,4,6-trihydroxybenzene-1,3,5-tricarbaldehyde, 3.5mmol of 5,5'-diamino-2,2'-bipyridine and 60mL of absolute ethanol , stirred at room temperature for 20 minutes, centrifuged and suction filtered the product, then added the solid obtained by suction filtration into N,N-dimethylformamide and stirred and refluxed at 160°C for 5 hours, then centrifuged and suction filtered, and then filtered the solid obtained by suction filtration The solid was added to absolute ethanol at 80°C, stirred and refluxed for 3 hours, then centrifuged and suction filtered, and finally the solid obtained by suction filtration was vacuum-dried at 80°C for 24 hours to obtain a covalent organic framework material. The synthetic route is as follows:

[0035]

[0036] 2) Mix 160mg of covalent organic framework material, 10mg of palladium acetate an...

Embodiment 2

[0038] A kind of covalent organic framework material supports Pd catalyst, and its preparation method comprises the following steps:

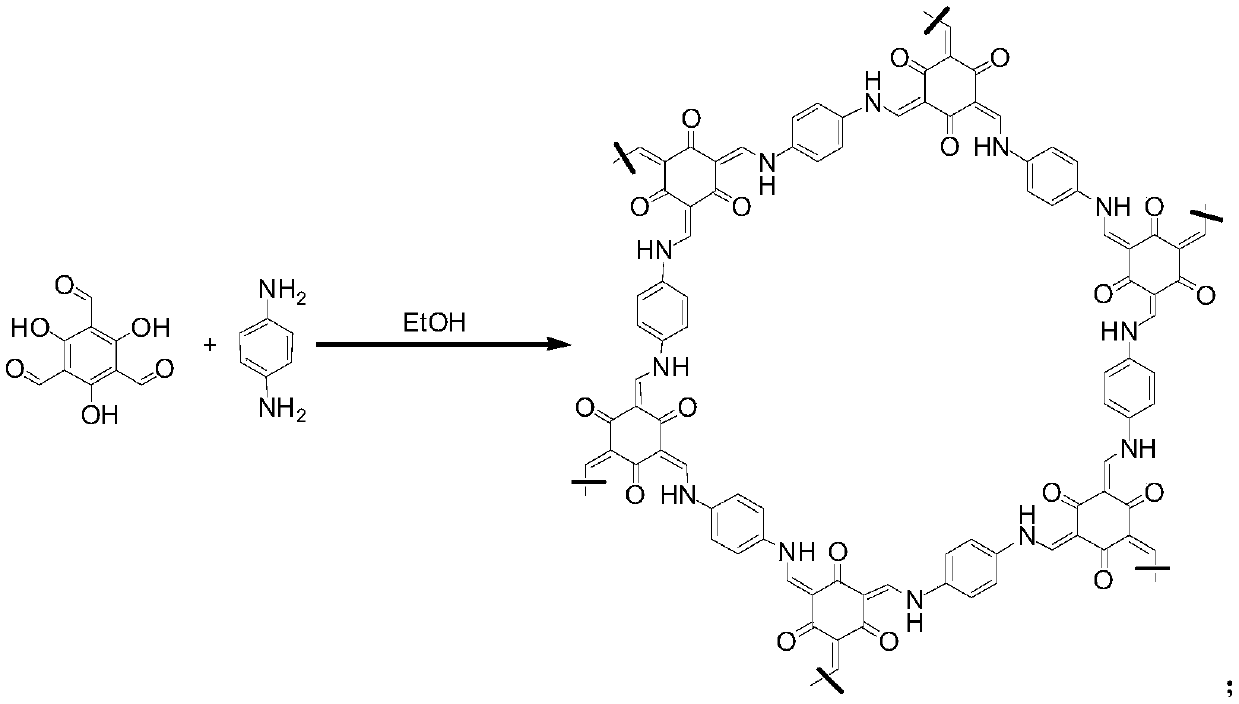

[0039] 1) Mix 2.4mmol of 2,4,6-trihydroxybenzene-1,3,5-tricarbaldehyde, 3.6mmol of p-phenylenediamine and 60mL of absolute ethanol, stir at room temperature for 20min, centrifuge and pump the product Filtrate, then add the solid obtained by suction filtration into N,N-dimethylformamide, stir and reflux at 160°C for 5h, then perform centrifugation and suction filtration, then add the solid obtained by suction filtration into absolute ethanol, stir and reflux for 3h at 80°C , followed by centrifugation and suction filtration, and finally the solid obtained by suction filtration was vacuum-dried at 80°C for 24 hours to obtain a covalent organic framework material. The synthesis route is as follows:

[0040]

[0041] 2) Mix 160mg of covalent organic framework material, 20mg of palladium acetate and 10mL of dichloromethane, stir at 25°C for 24h f...

Embodiment 3

[0044] A kind of covalent organic framework material supports Pd catalyst, and its preparation method comprises the following steps:

[0045]1) Mix 2.0mmol of 2,4,6-trihydroxybenzene-1,3,5-tricarbaldehyde, 4.0mmol of benzidine and 60mL of absolute ethanol, stir at room temperature for 20min, centrifuge and filter the product, Then add the solid obtained by suction filtration into N,N-dimethylformamide and stir and reflux at 160°C for 5h, then perform centrifugation and suction filtration, then add the solid obtained by suction filtration into absolute ethanol and stir at reflux for 3h at 80°C, and then Carry out centrifugation and suction filtration, and finally place the solid obtained by suction filtration at 80°C for 24 hours in vacuum to obtain a covalent organic framework material. The synthesis route is as follows:

[0046]

[0047] 2) Mix 160mg of covalent organic framework material, 20mg of palladium acetate and 10mL of dichloromethane, stir at 25°C for 24h for impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com