Chitosan catheter and its 3D printing device and printing method

A technology of 3D printing and printing device, applied in the field of 3D printing, can solve the problems of complex shape and structure of the catheter, difficult to meet individual needs, etc., and achieve the effects of excellent mechanical properties, increased convenience, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] [Preparation of Chitosan Slurry]

[0054] Select different acids and acid solutions with different mass concentrations to prepare chitosan slurry, as shown in Table 1 below.

[0055] The performance of the chitosan slurry prepared by the proportioning of table 1 is tested:

[0056] Tensile strength is tested according to GB / T1040-2006;

[0057] Cytotoxicity was tested according to ISO 10993-5 2016, and the cells used for the test were mouse fibroblasts (L-929, provided by the Cell Bank of the Chinese Academy of Sciences). Cell viability >70% indicates no potential cytotoxicity.

[0058] The preparation of table 1 chitosan slurry

[0059]

[0060]

Embodiment 2

[0061] It can be seen from Table 1 that the chitosan slurry containing glycolic acid (the mass concentration of glycolic acid is 30wt.%, the mass ratio of chitosan and acid solution is 1:4) has no potential cytotoxicity. This was used as a printing material for the following Examples 2-4. Example 2 A printing device and printing method combining an extrusion 3D printing module and a rotating module

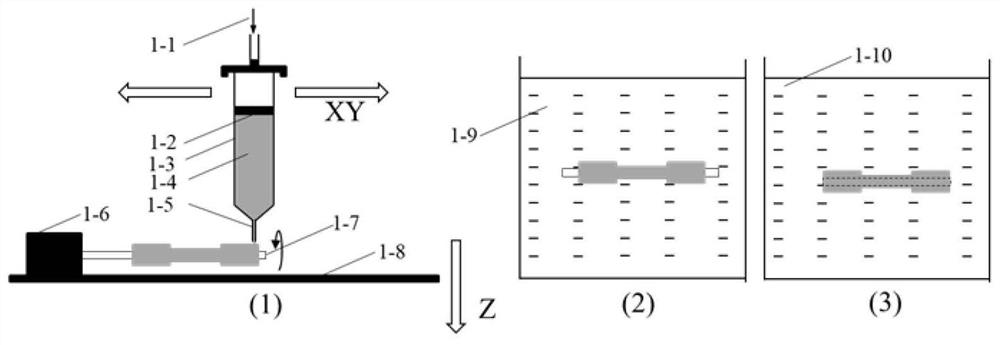

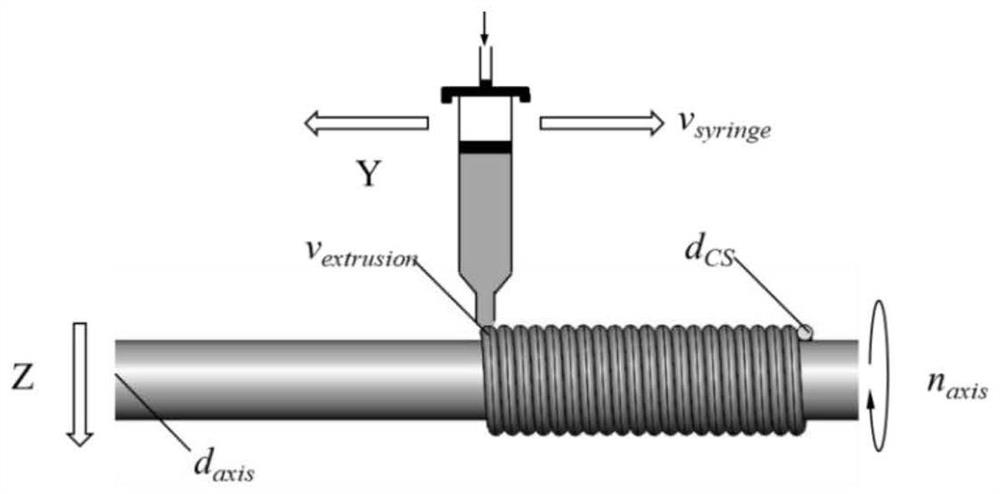

[0062] Such as figure 1 In the printing device shown, the extruded 3D printing module was combined with the rotating module to prepare a chitosan catheter with a simple structure. The extrusion 3D printing module includes a gas inlet 1-1, a piston 1-2, a barrel 1-3 and a needle 1-5, and the barrel 1-3 contains chitosan slurry 1-4. The rotary module includes a stepper motor 1-6 and a rotary shaft 1-7 driven by the stepper motor 1-6, the rotary shaft 1-7 is used to support the chitosan slurry deposited thereon, and the stepper motor 1-6 places 1-8 on a 3D printing platform. Prin...

Embodiment 3

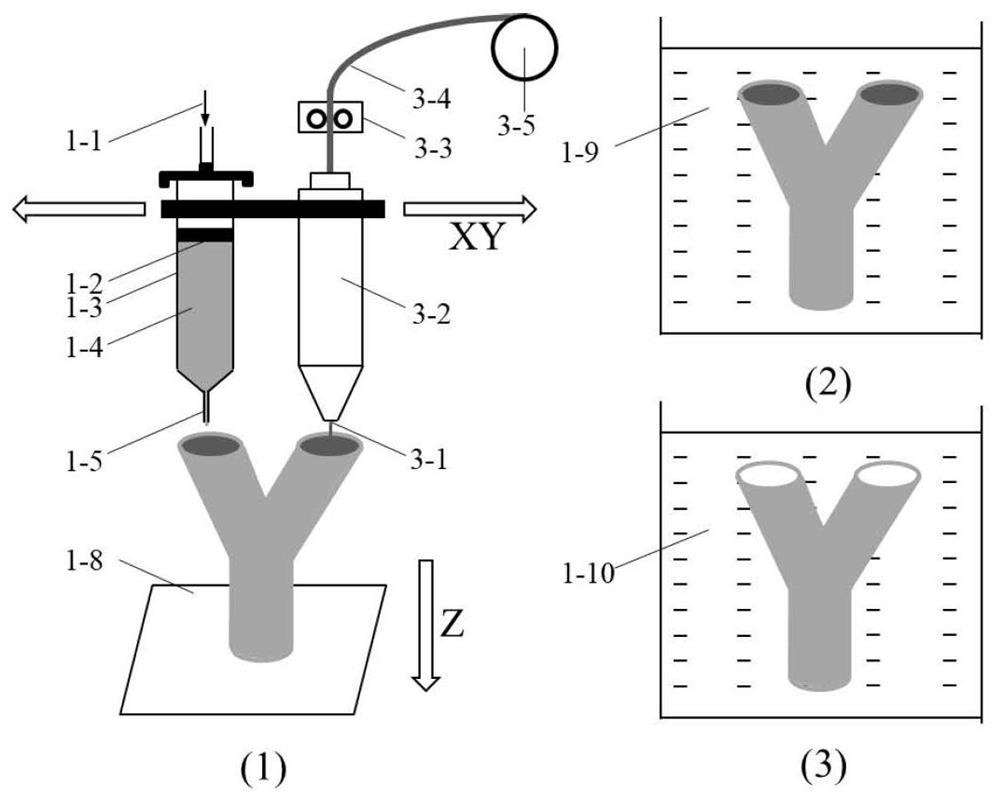

[0089] Example 3 Printing device and printing method combining extrusion 3D printing module and fused deposition module

[0090] like image 3 The extrusion 3D printing module shown is combined with the fused deposition module for the fabrication of chitosan catheters with complex structures.

[0091] The structure of extrusion 3D printing module is identical with embodiment 2, and fused deposition module comprises PVA coil 3-5, the PVA thread 3-4 that is wound on the PVA coil 3-5, feeder 3-3, heater 3-2 and nozzle 3-1. Printing process:

[0092] Under program control, the feeder 3-3 passes the PVA wire 3-4 in the PVA coil 3-5 to the heater 3-2. The PVA thread is melted and extruded through the nozzle 3-1 under the pressure provided by the feeder 3-3.

[0093] Under the action of the gas pressure fed into the gas inlet 1-1, the pressure is transmitted to the chitosan slurry through the piston 1-2, and the slurry is extruded from the needle 1-5.

[0094] Both the extrusion...

PUM

| Property | Measurement | Unit |

|---|---|---|

| speed | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com