Thioether oxidation method

A thioether oxidation and thioether technology, applied in chemical instruments and methods, organic chemistry, chemical/physical processes, etc., can solve the problems of reducing the production cost of sulfoxide and limiting the application range of peroxide oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

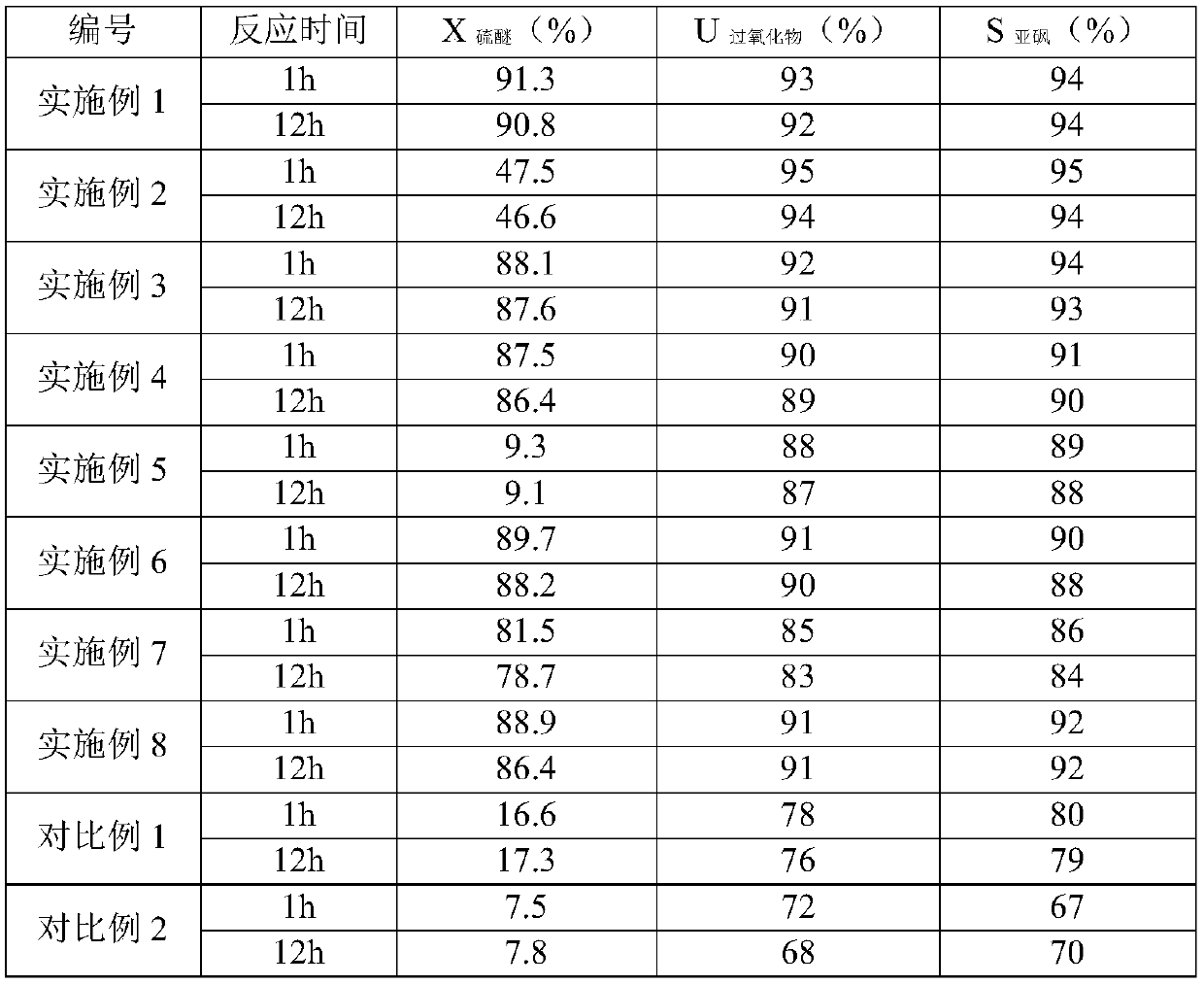

Examples

preparation example 1

[0052] Put 50g of urea in a crucible, cover and seal it, place it in a muffle furnace at 450°C and roast for 8 hours to obtain carbon nitride particles A. The average particle size is 400nm, and carbon nitride particles with a particle size of 20-100nm The weight ratio of carbon nitride to the total weight of carbon nitride is 9%, and the nitrogen content is about 61% by weight.

preparation example 2

[0054] Put 40g of urea in a crucible, cover and seal it, place it in a muffle furnace at 550°C and bake for 5 hours to obtain carbon nitride particles B. The average particle size is 200nm, and carbon nitride particles with a particle size of 20-100nm The weight ratio of carbon nitride to the total weight of carbon nitride is 16%, and the nitrogen content is about 61% by weight.

preparation example 3

[0056] Put 60g of urea in a crucible, cover and seal it, place it in a muffle furnace at 650°C and roast for 2 hours to obtain carbon nitride particles C. The average particle size is 600nm, and carbon nitride particles with a particle size of 20-100nm The proportion of the weight of carbon nitride to the total weight of carbon nitride is 2.5%, and the nitrogen content is about 61% by weight.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com