Synthesis process of polymer polyester polyol

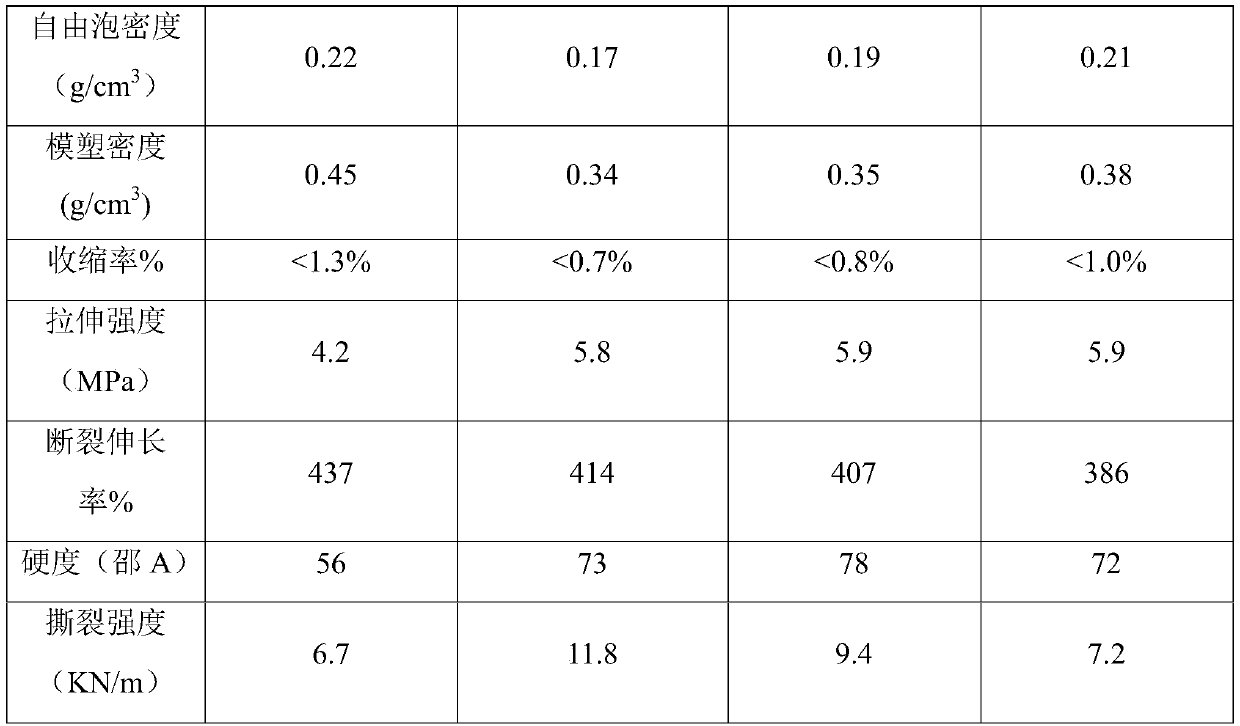

A technology of polyester polyol and synthesis process, applied in the field of synthesis technology of polymer polyester polyol, can solve the problems of small molecular weight of dispersant, decreased tear strength of products, poor activity of tertiary carbon double bonds, etc., and achieve less filter residues. The effect of high content, high tensile strength and high tear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

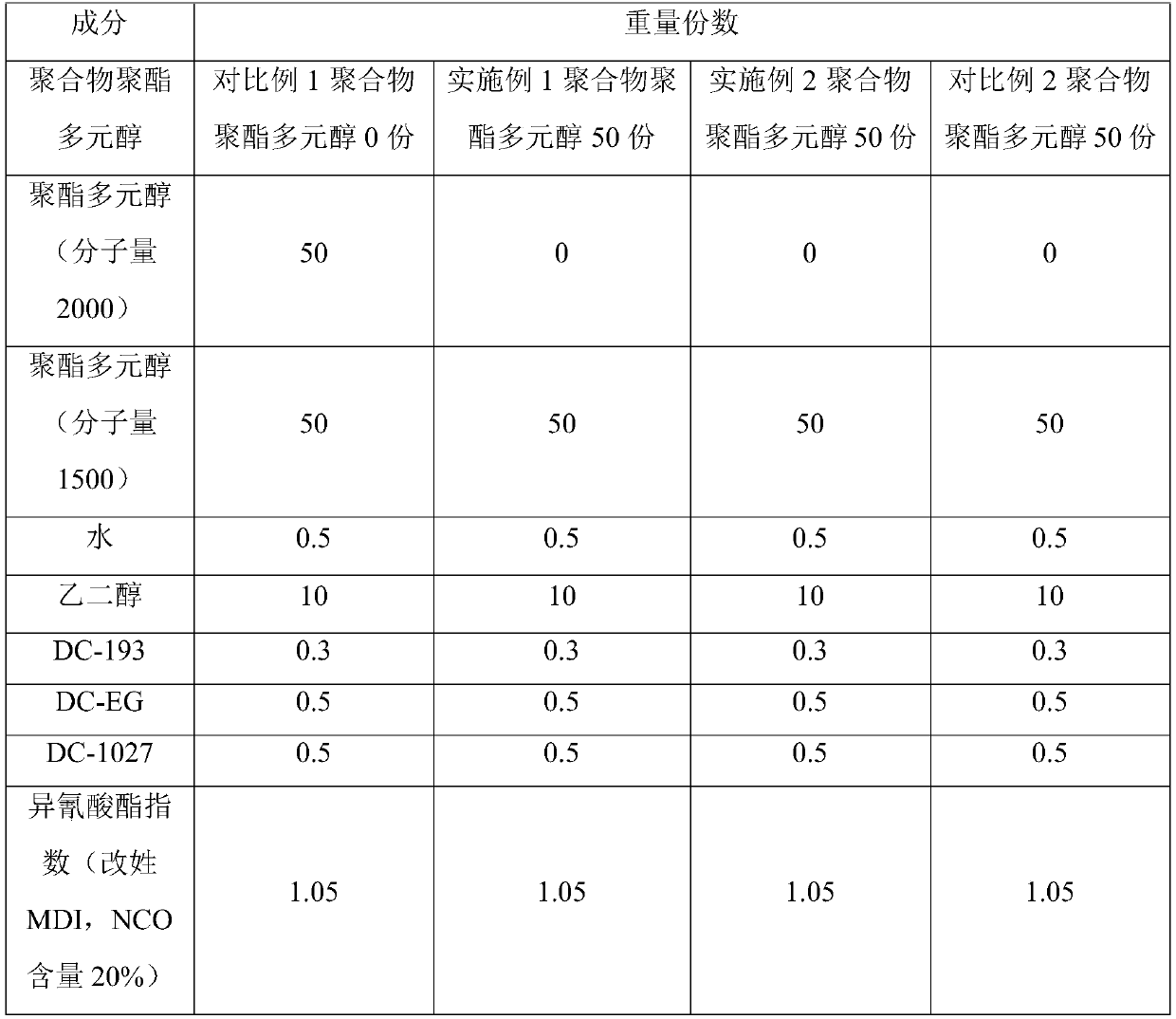

Examples

Embodiment 1

[0026] (1) Preparation of dispersant

[0027] The temperature is controlled at 25°C, the molecular weight is 4000g / mol, the polymerized monomer is propylene oxide, and the polyether polyol with a functionality of 2 (DL-4000 produced by Bluestar Dongda) is 4000g, TDI 350g, TMI 202g, molecular weight 2000g / mol , Polymerized monomer ethylene glycol and adipic acid, 4000g of polyester polyol with a functionality of 2, mix well, slowly add 0.24g of stannous octoate dropwise, under the protection of nitrogen atmosphere, stir slowly and heat up at 70°C for 3h into, spare.

[0028] (2) Synthesis of Polymer Polyester Polyol

[0029] The synthesis of polymer polyester polyol is to control the temperature at 120°C and the pressure between 0.05-0.45MPa, add the top material dropwise to the bottom material, and the time for adding the top material is 2 hours. React for 1 hour under the pressure of 0.4MPa, then remove the pressure in the reactor, remove the volatile matter in a vacuum, an...

Embodiment 2

[0031] (1) Preparation of dispersant

[0032] The temperature is controlled at 25°C, the molecular weight is 4000g / mol, the polymerized monomer is propylene oxide, and the polyether polyol with a functionality of 2 (DL-4000 produced by Bluestar Dongda) is 4000g, TDI 350g, TMI 202g, molecular weight 2000g / mol , Polymerized monomer ethylene glycol, propylene glycol and adipic acid, 4000g of polyester polyol with a functionality of 2, mixed uniformly, slowly added dropwise catalyst dibutyltin dilaurate 0.3g, under the protection of nitrogen atmosphere, stirred and slowly raised the temperature at 70 ℃ under the conditions of reaction for 3h made, spare.

[0033] (2) Synthesis of Polymer Polyester Polyol

[0034] The synthesis of polymer polyester polyol is to control the temperature at 120°C and the pressure between 0.05-0.4MPa, add the top material dropwise to the bottom material, and the time for adding the top material is 2.1 hours. React for 1 hour under the pressure of 0.4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com