Blast furnace smelting method for quickly acquiring stable indexes through ordinary ore and schreyerite interchange

A stable index, blast furnace smelting technology, applied in the field of blast furnace smelting, can solve the problems of low accuracy, complexity, time-consuming, etc., and achieve the effect of simple method and accurate index calculation quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

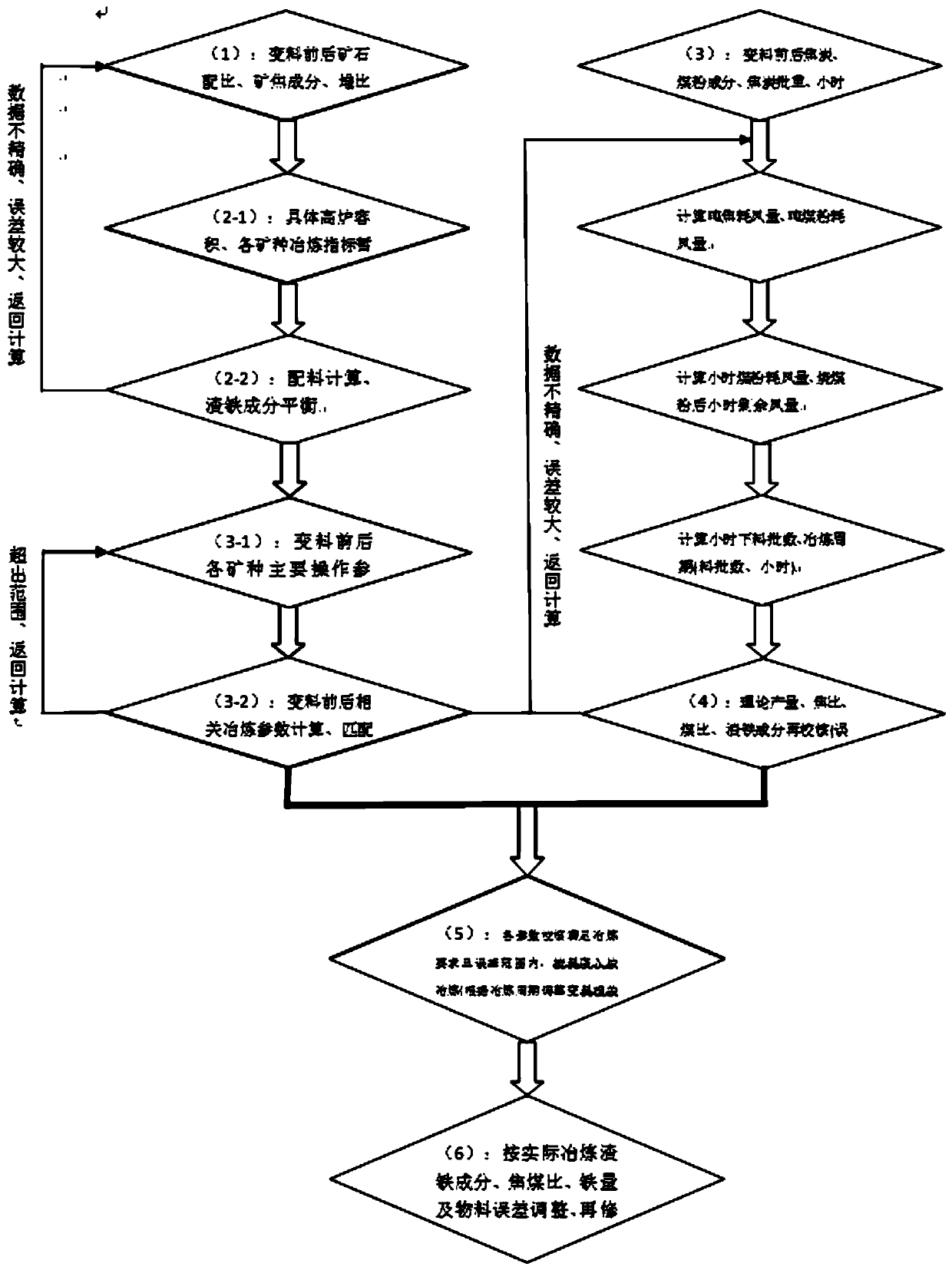

Method used

Image

Examples

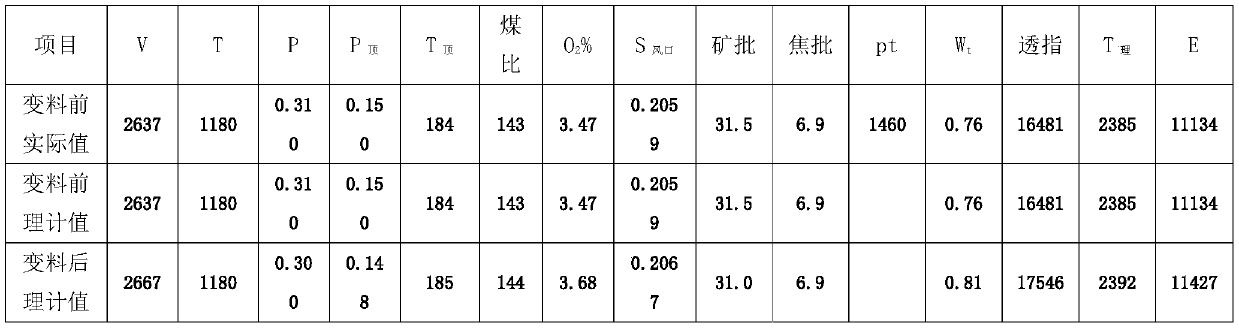

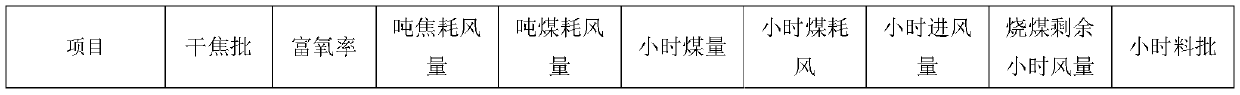

Embodiment 1

[0091]Step (1), after the blast furnace is overhauled and the output reaches the standard, the smelting of titanium slag in the vanadium-titanium ore is resumed, and the materials used for the furnace are ordinary ore (including sinter, self-produced high-silica acidic oxidizing pellets and conventional low-silicon blocks) ore), and the charge structure of vanadium-titanium ore (including sinter, high-titanium pellets, and high-silicon lump ore) after changing the material.

[0092] Before the material change: the chemical composition of the sinter is: Fe is 52.36%, SiO 2 6.10%, CaO 12.95%, Al 2 O 3 2.05%, MgO 2.45%, TiO 2 is 0.46%, S is 0.045%, and the bulk density is 1.88t / m 3 ; Among them, the chemical composition of self-produced high siliceous acid oxidizing pellets is: Fe is 59.80%, SiO 2 9.50%, CaO 0.76%, Al 2 O 3 2.09%, MgO 0.77%, TiO 2 is 0.987%, and the bulk density is 2.50t / m 3 ; The chemical composition of low silicon lump ore is: Fe is 53.73%, SiO 2 4.00%...

Embodiment 2

[0155] The calculation formula and process of the following steps are the same as those in Example 1.

[0156] Step (1), the blast furnace is planned to have a long-term off-air maintenance, and the titanium slag smelting in the vanadium-titanium ore is converted into ordinary ore smelting, and the titanium slag smelting charge structure in the vanadium-titanium ore is sinter, high-titanium pellets, high-silicon lump ore; After the material change, the structure of ordinary ore charge is sinter, high-titanium pellet, and high-silicon lump ore;

[0157] Before the material change: the chemical composition of the sinter is: Fe is 52.86%, SiO 2 5.80%, CaO 12.10%, Al 2 O 3 1.98%, MgO 2.35%, TiO 2 is 0.37%, S is 0.040%, and the bulk density is 1.87t / m 3 ; The chemical composition of high titanium pellets is: Fe is 54.01%, SiO 2 4.26%, CaO 1.23%, Al 2 O 3 1.89%, MgO 1.45%, TiO 2 is 10.565%%, and the bulk density is 2.31t / m 3 ; The chemical composition of high silicon lump o...

Embodiment 3

[0191] The calculation formula and process of the following steps are the same as in Example 1.

[0192] Step (1), in the normal smelting process, it is calculated and converted to vanadium-titanium ore medium-titanium slag smelting with better economic efficiency under the current conditions. Materials used before changing materials: sintered ore, self-produced high silicic acid oxidizing pellets , Conventional low-silicon lump ore, after changing the material, it is a vanadium-titanium ore charge structure (including sinter, high-titanium pellets, and high-silicon lump ore);

[0193] Before material change: the chemical composition of the sintered ore is: Fe is 51.66%, SiO 2 6.19%, CaO 12.76%, Al 2 o 3 2.15%, MgO 2.46%, TiO 2 is 0.78%, S is 0.038%, and the bulk specific gravity is 1.85t / m 3 ; The chemical composition of self-produced high silicic acidic oxidizing pellets is: Fe is 58.5%, SiO 2 9.596%, CaO 0.80%, Al 2 o 3 2.20%, MgO 0.76%, TiO 2 1.076%, pile specific ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk specific gravity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com