Lithium ion supercapacitor negative electrode lithium pre-embedding method

A technology for supercapacitors and pre-embedded lithium, which is applied in the direction of hybrid capacitor electrodes, capacitors, electrolytic capacitors, etc., can solve the problems of large ion concentration attenuation, achieve the effects of simplifying the assembly process, reducing costs, and improving cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

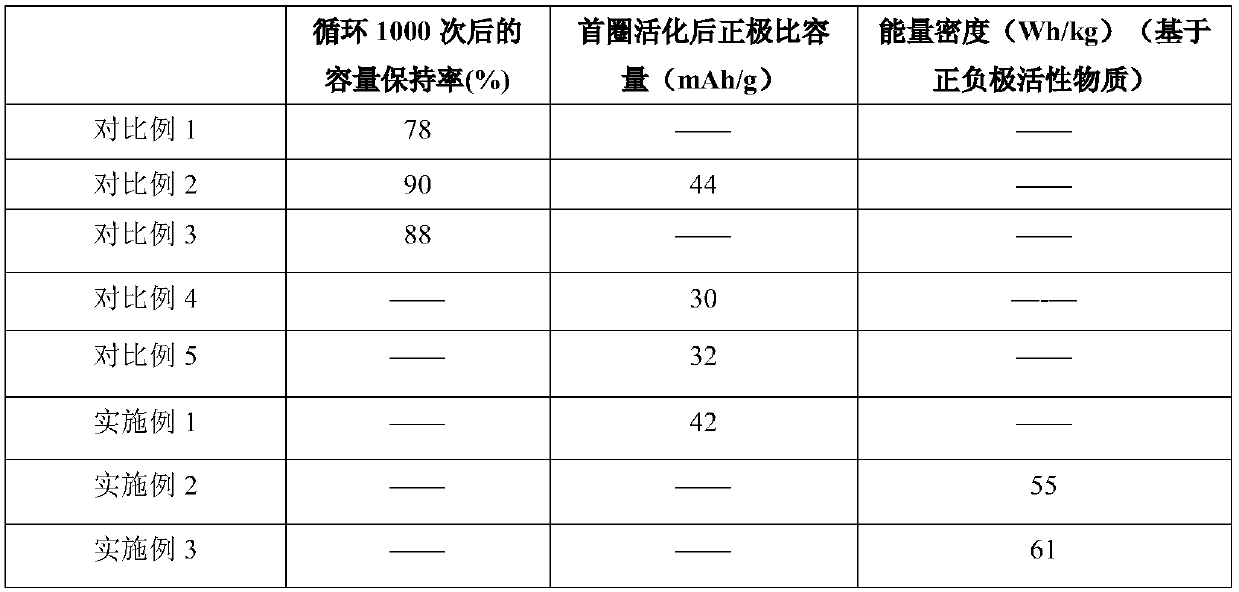

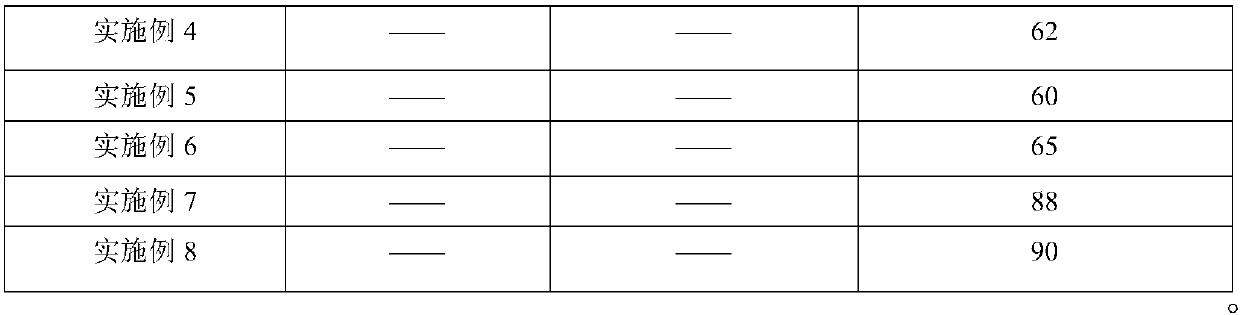

Embodiment 1

[0032] Adding 22% Li by mass to the activated carbon positive electrode 2 C 2 , with lithium sheet as the negative electrode, 1M LiPF6 / EC:DEC (volume ratio 1:1) as the electrolyte, and cellgard2400 as the diaphragm to assemble the half-cell. The battery is charged for the first time at a rate of 0.05C, and the cut-off voltage of charging reaches 4.2V. The depth of lithium embedded in the negative electrode is 62%, and the specific capacity of the positive electrode after the first cycle of activation is tested.

Embodiment 2

[0034] Adding 10% Li by mass to the activated carbon positive electrode 2 C 2 , with hard carbon as the negative electrode, 1M LiPF6 / EC:DEC (volume ratio 1:1) as the electrolyte, and cellgard2400 as the diaphragm to assemble the lithium-ion supercapacitor. Charge the battery for the first time at a rate of 0.05C, charge the cut-off voltage to 4.2V, and achieve a 50% depth of pre-intercalated lithium on the negative electrode.

Embodiment 3

[0036] Adding 30% Li by mass to the activated carbon positive electrode 2 C 2 , with hard carbon as the negative electrode, 1M LiPF6 / EC:DEC (volume ratio 1:1) as the electrolyte, and cellgard2400 as the diaphragm to assemble the lithium-ion supercapacitor. Charge the battery for the first time at a rate of 0.05C, charge the cut-off voltage to 4.2V, and achieve a depth of 85% of pre-intercalated lithium on the negative electrode.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com