A method for recovering the capacity of batteries with extended storage

A recovery method and battery capacity technology, applied in the measurement of electrical variables, secondary battery repair/maintenance, secondary battery charging/discharging, etc. The operability and applicability are strong, the battery management cost is saved, and the process is simple and controllable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027]The lead-acid battery 6-EVF-100 for electric road vehicles has been stored for nearly 1 year. The basic parameters of the battery are: rated voltage 12V (6 cells), rated capacity 100AH, and rated current 33.3A (3 hour rate current).

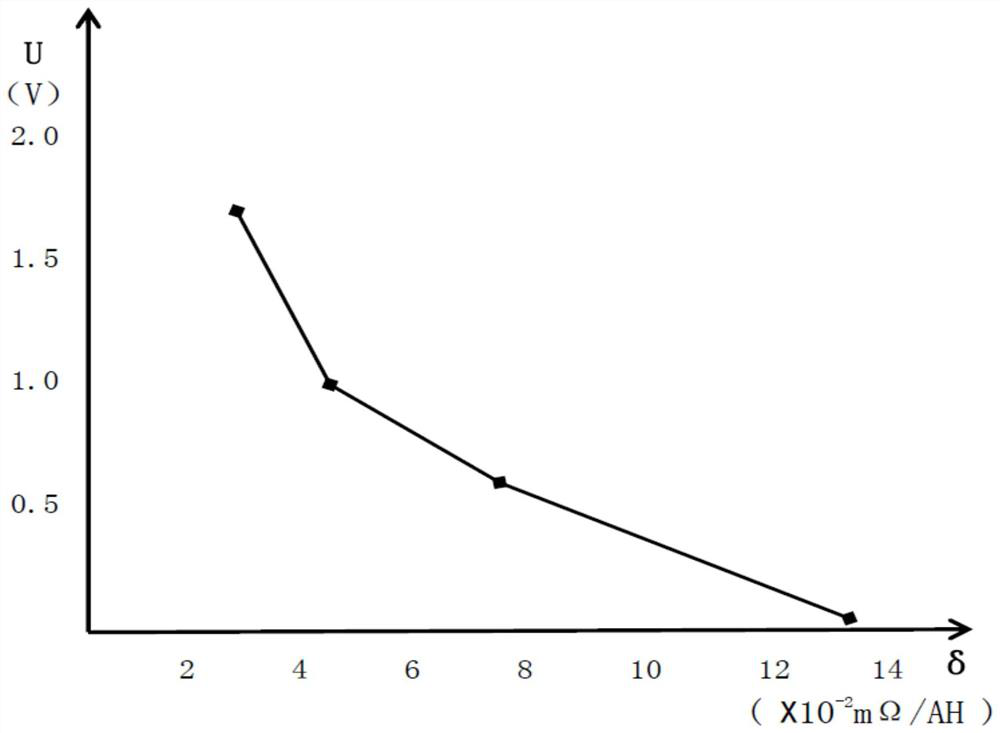

[0028]1) Solve the reference model curve of battery internal resistance / rated capacity ratio δ and discharge depth U

[0029]In the first step, given the new battery, the battery stored for six months, one year and two years, the internal resistance values of 3.4mΩ, 4.5mΩ, 7.8mΩ, and 13.8mΩ are measured respectively; calculate the ratio of the internal resistance of the battery to the rated capacity δ1, δ2, δ3 , Δ4 are 3.4×10-2mΩ / AH, 4.5×10-2mΩ / AH, 7.8×10-2mΩ / AH, 13.8×10-2mΩ / AH;

[0030]The second step, given the new battery, storage for half a year, one year, and two years of battery discharge depth U1, U2, U3, U4 values are 1.67V, 1.00V, 0.67V, 0V (calculated based on a single cell 2V rated voltage);

[0031]The third step is based on the reference mod...

Embodiment 2

[0034]The lead-acid battery 6-EVF-100 for electric road vehicles has been stored for nearly 1 year. The basic parameters of the battery are: rated voltage 12V (6 cells), rated capacity 100AH, and rated current 33.3A (3 hour rate current).

[0035]1) Implementation of repair process

[0036]The first step is to measure the internal resistance of the battery as 7.7mΩ (milliohm). Calculate the internal resistance / capacity ratio δ0 as 7.7×10-2mΩ / AH;

[0037]In the second step, from the reference model curve of the battery internal resistance / rated capacity ratio δ and the depth of discharge U, the U value corresponding to δ0 is found to be 0.67V, and the value of U0 corresponding to the rated voltage 12V battery is calculated as 0.67×6= 4.02V;

[0038]The third step is to calculate the four-stage cascade discharge current whose values are 33.3A (1.0I), 16.7A (0.5I), 8.35A (0.25I), 4.175A (0.125I);

[0039]The fourth step is to calculate the current value of the four-stage cascade constant current vo...

Embodiment 3

[0048]The lead-acid battery 4-EVF-150 for electric road vehicles has been stored for nearly 1.5 years. The basic parameters of the battery are: rated voltage 8V (4 cells), rated capacity 150AH, and rated current 50.0A (3 hour rate current).

[0049]1) Implementation of repair process

[0050]The first step is to measure the internal resistance of the battery as 10.2mΩ. Calculate the internal resistance / capacity ratio δ0 as 6.8×10-2mΩ / AH;

[0051]In the second step, from the reference model curve of the battery internal resistance / rated capacity ratio δ and the discharge depth U, the U0 value corresponding to δ0 is found to be 0.83V, and the discharge repair depth U value corresponding to the rated voltage 8V battery is calculated to be 0.83×4 = 3.32V;

[0052]The third step is to calculate the four-stage cascade discharge current and its values are 50.0A (1.0I), 25.0A (0.5I), 12.5A (0.25I), 6.25A (0.125I);

[0053]The fourth step is to calculate the current value of the four-stage cascaded const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com