Sugarcane planting method for improving mechanical harvesting efficiency and quality of sugarcanes

A planting method and sugarcane technology, applied in planting methods, botanical equipment and methods, seed coating/seed dressing, etc., can solve the problems of easy slippage of machinery, inability to operate normally, and low mechanical harvesting efficiency, and reduce operations. area, improve work efficiency, and facilitate the effect of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The test site is located in Guangxi sugarcane double-high base, and the cultivated sugarcane variety is Guitang 44. The cultivation method comprises the steps:

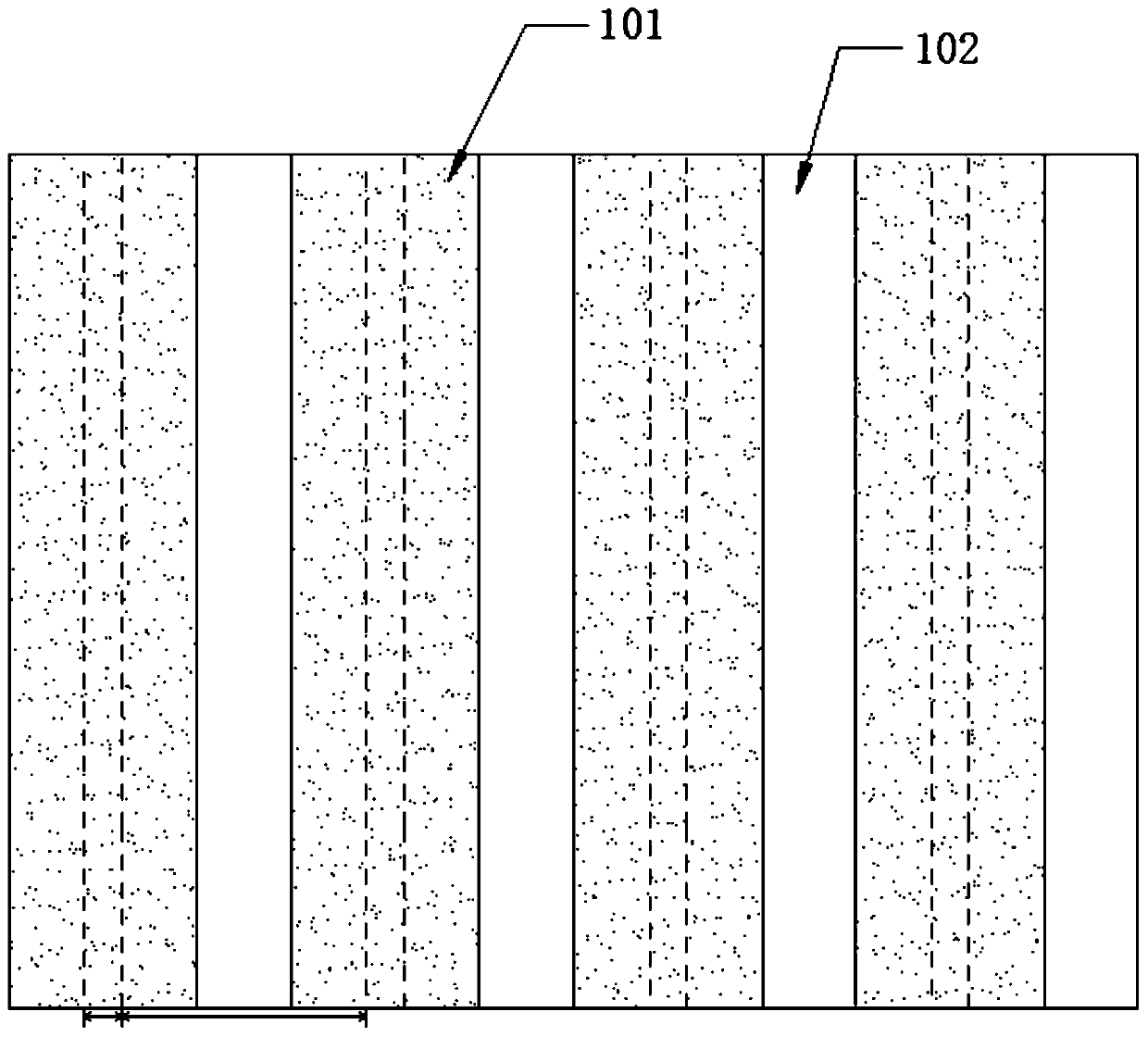

[0058] Step S1, soil preparation: if figure 1 As shown, the 1 / 3 area of the whole field is the fixed machine farming road 101, and 2 / 3 is the farming area 102; the width of the farming area 101 is 1.20m, and the fixed machine farming road 102 is reserved in the adjacent two farming areas 101, and the fixed machine farming road 102 width It is 0.60m. Use GPS navigation and positioning to carry out subsoiling operations of more than 50cm deep plowing with the subsoiling actuator in the cultivation area 101, and open a planting ditch with a depth of 30-35cm in the middle of the cultivation area 101, without plowing the fixed machine cultivation road 102.

[0059] Step S2, seed stem preparation: strip healthy seed stems and dry them for 1-2 days, then cut them into standard double-bud sugarcane seeds with a see...

Embodiment 2

[0065] The test site is located in Guangxi sugarcane double-high base, and the cultivated sugarcane variety is Guitang 44. The machinery that cultivation process uses is identical with embodiment 1, and cultivation method comprises the steps:

[0066] Step S1, soil preparation: if figure 1 As shown, the 1 / 3 area of the whole field is the fixed machine farming road 101, and 2 / 3 is the farming area 102; It is 0.8m. Use GPS navigation and positioning to carry out subsoiling operations of more than 50cm deep plowing with the subsoiling actuator in the cultivation area 101, and open a planting ditch with a depth of 30-35cm in the middle of the cultivation area 101, without plowing the fixed machine cultivation road 102.

[0067] Step S2, seed stem preparation: strip healthy seed stems and dry them for 1-2 days, then cut them into standard double-bud sugarcane seeds with a seed cutter, and the length of the sugarcane seeds is 20-25cm. The cut sugarcane seeds are soaked in the c...

Embodiment 3

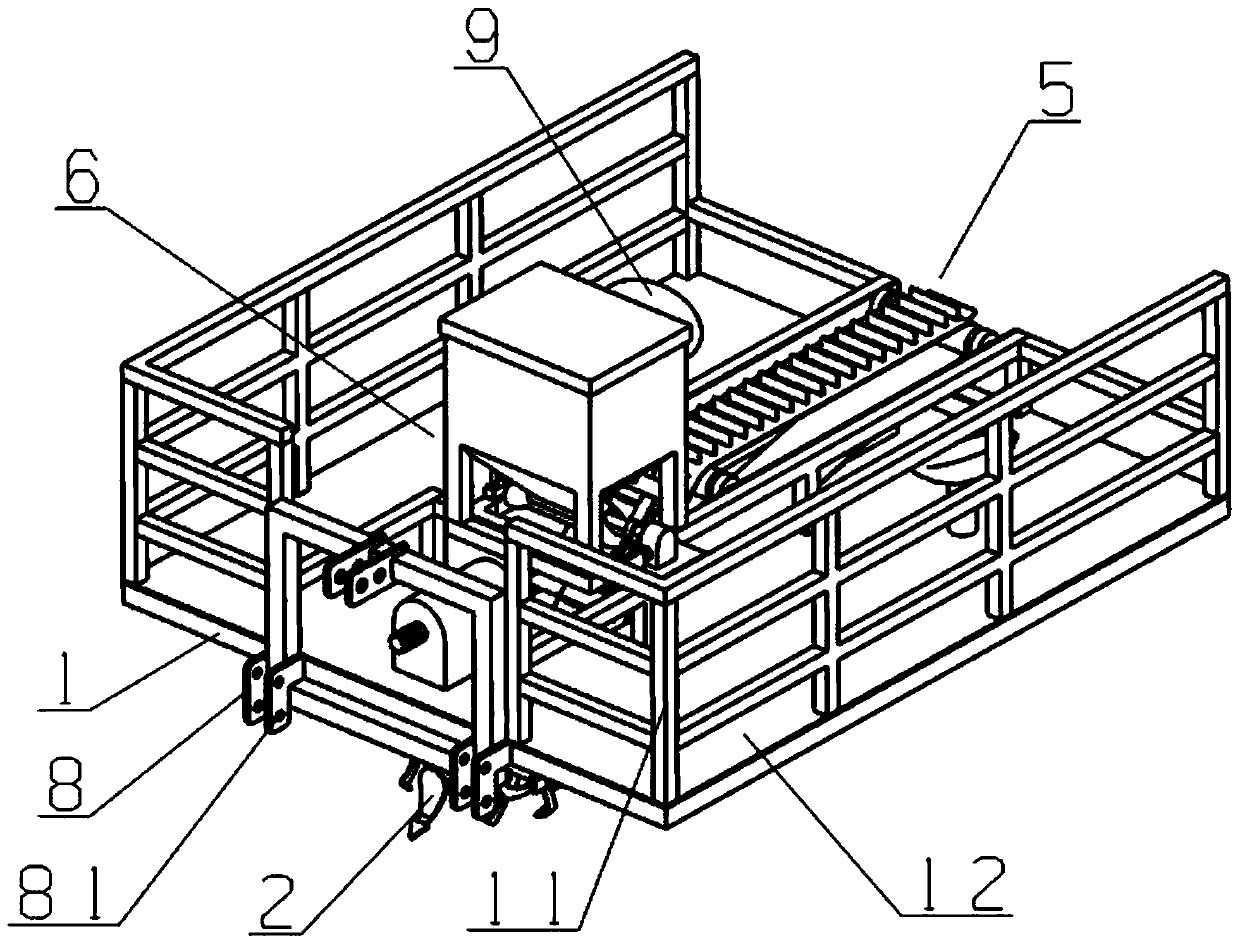

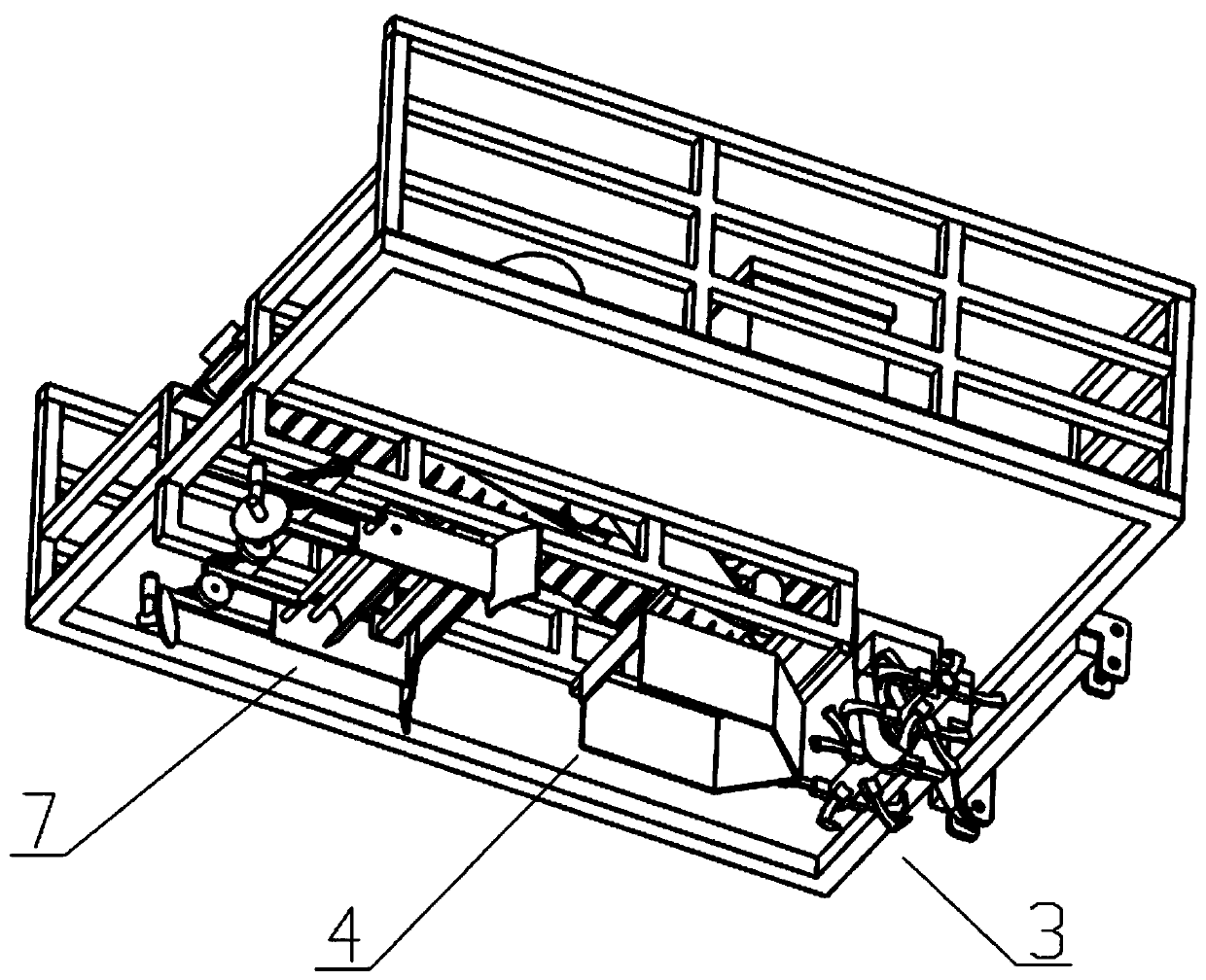

[0074] Such as Figure 2-8As shown, the integrated sugarcane planter used in the foregoing embodiment comprises: a frame 1, a rotary plow 2, a rotary knife group 3, a ditch opener 4, a seed meter 5, a fertilizer applicator 6, a soil covering device 7, Traction seat 8, seat stool 9, partition 11, fence 12, rotary shaft 31, rotary blade 32, first gear box 33, spline shaft 34, seed discharge port 41, seed inlet port 42, soil dividing plate 43 , Soil-distributing blade 44, guide plate 45, connecting plate 46, conveyor belt 51, roller 52, spacer bar 53, layering bar 54, spring 55, second hydraulic pump 56, fertilizer inlet 61, fertilizer outlet 62, fertilizer storage box 63, fertilizer discharge cylinder 64, screw rod 65, second gear box 66, first hydraulic pump 67, shaft seat 68, soil inlet 71, soil discharge outlet 72, cover film rotating shaft 73, arc plate 74, soil covering plate 75, Membrane cover assembly support 76, connecting shaft 77, film pressing wheel arm 78, film pres...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com