Processing method of multi-strain composite fermented egg product

A technology of compound fermentation and processing method, which is applied in the processing of fermented egg products and the field of egg product processing, can solve the problems of inability to obtain compound fermented egg products with multiple bacteria, and undisclosed processing methods for compound fermented egg products with multiple bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

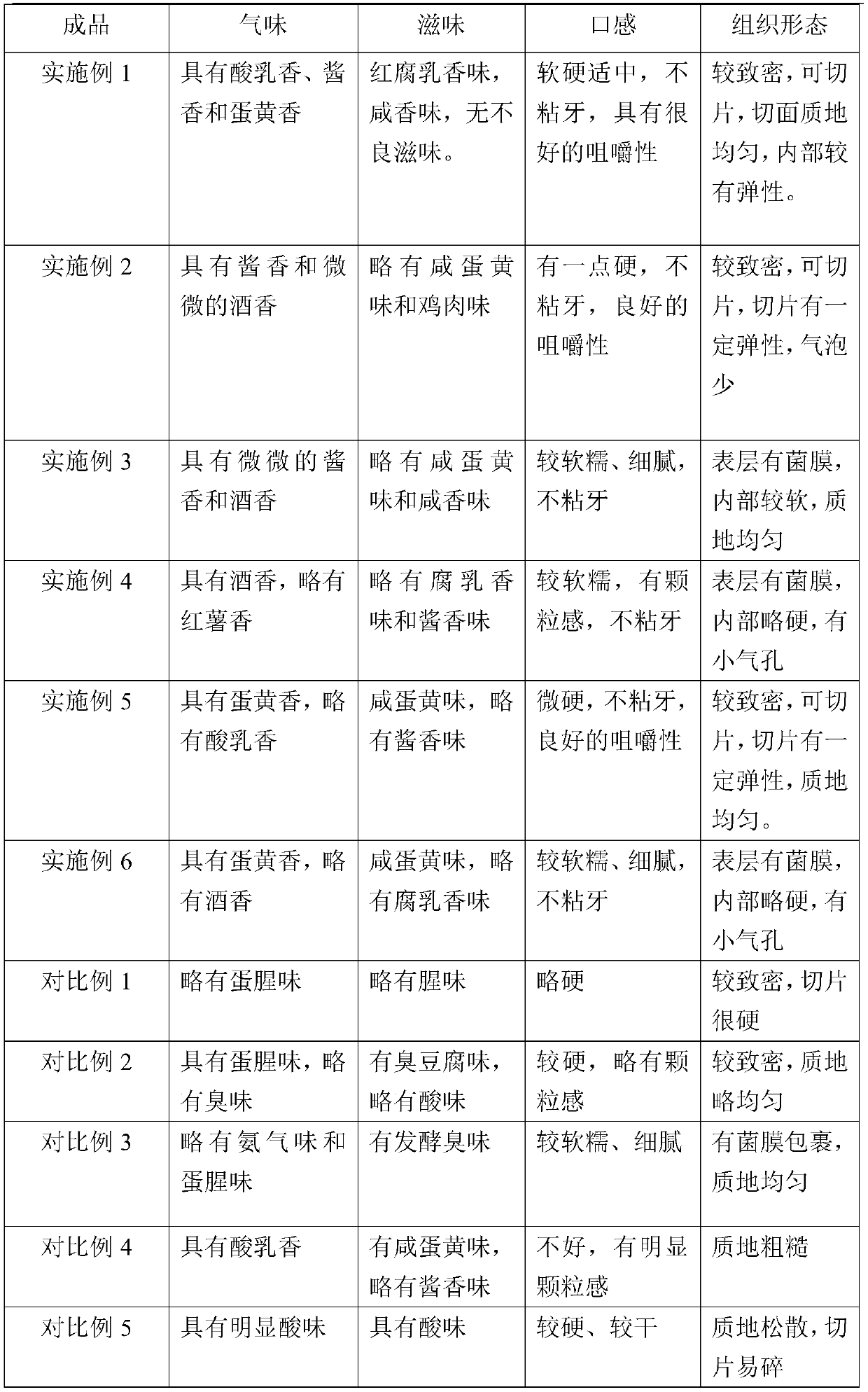

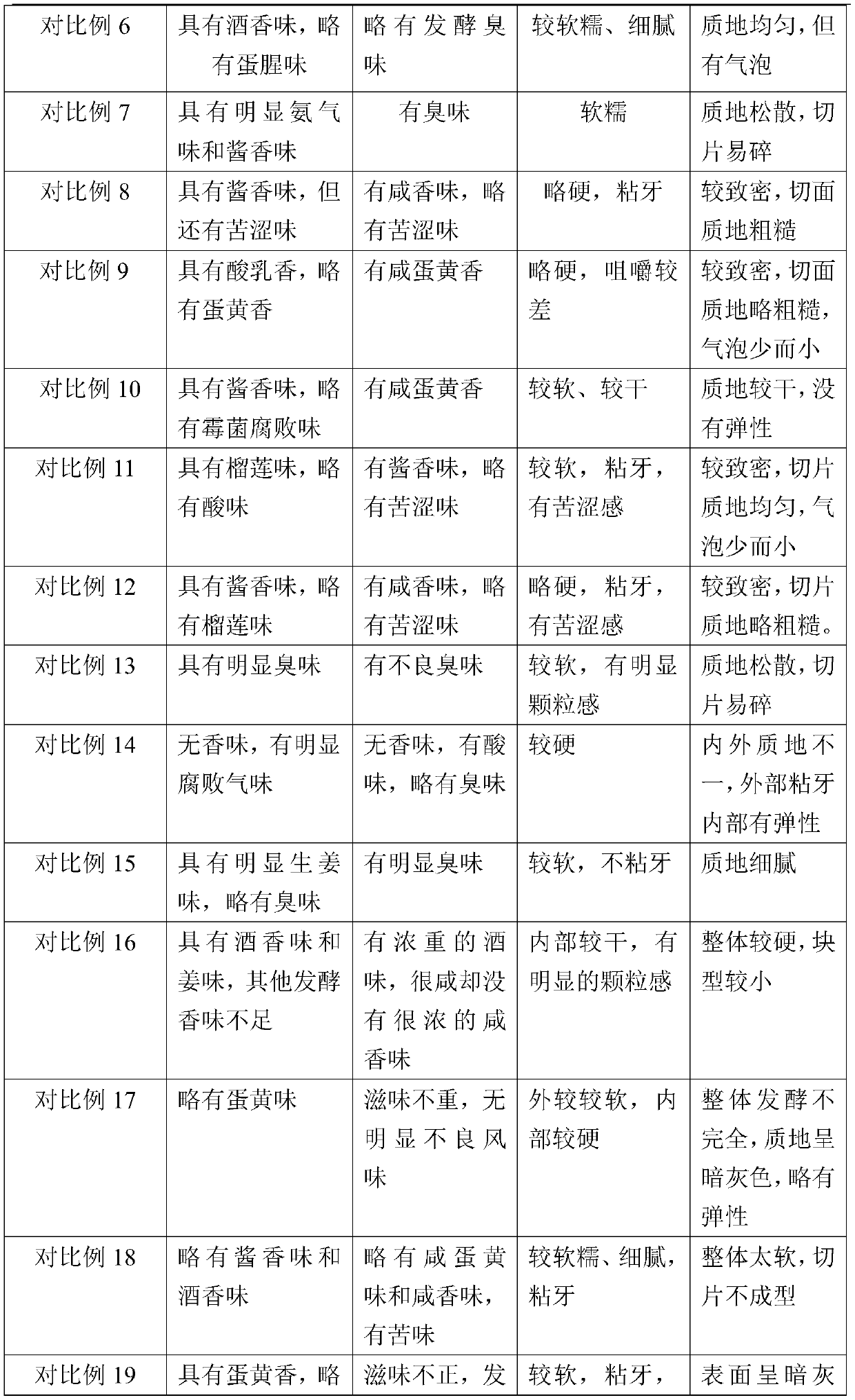

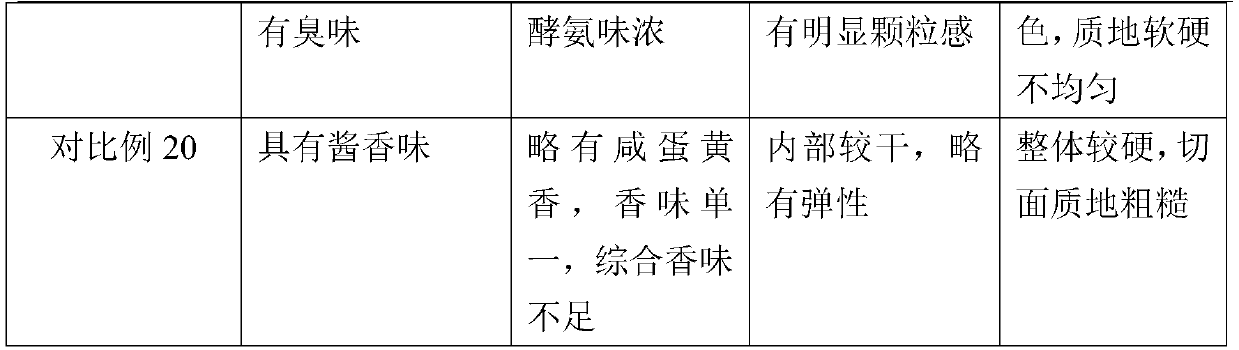

Examples

Embodiment 1

[0023] This embodiment is the best embodiment, and the specific operation is to obtain 100 kg of whole egg liquid through cleaning, disinfection, and beating of fresh eggs, add 0.5 kg of salt, 0.001 kg of sodium bisulfite, and 3 kg of fructose syrup, stir evenly, and heat to Keep at 63°C for 20 minutes to sterilize, cool the egg liquid to 35°C, add 0.1 kg of Streptococcus thermophilus preparation and 0.2 kg of Saccharomyces ruxie preparation, and ferment at 32°C for 3 hours. The fermented egg liquid is poured into the mould, heated by steam at 90°C for 120 minutes to denature and mature the egg liquid, take the egg base out of the mold, cut the egg base into small pieces of 6.5cm×5.5cm×3.2cm, cut the small pieces into The egg blanks are erected and placed on a wooden perforated sieve with an interval of 5.0 cm between the egg blanks. Mix the spores of Wutongqiao Mucor and Aspergillus niger at a ratio of 10:3 to prepare a mixed preparation, weigh 0.15 kg of the mixed preparatio...

Embodiment 2

[0025] Fresh eggs are washed, sterilized, and beaten to obtain 100kg of whole egg liquid. Add 0.8kg of salt, 0.003kg of sodium bisulfite, and 2.2kg of fructose syrup and stir evenly. Heat to 62°C while stirring, keep for 27 minutes to sterilize, and cool the egg liquid. To 35°C, add 0.2kg of Lactobacillus bulgaricus preparation and 0.3kg of Hansenula yeast preparation, and ferment at 34°C for 4 hours. The fermented egg liquid is poured into the mould, heated by steam at 92°C for 50 minutes to denature and mature the egg liquid, take the egg base out of the mold, cut the egg base into small pieces of 10cm×7cm×5cm, and vertically Put them together on a wooden perforated sieve, with an interval of 4.0cm between egg blanks. Mix the spores of Wutongqiao Mucor and Aspergillus niger at a ratio of 5:2 to prepare a mixed preparation, weigh 0.2kg of the mixed preparation and add it to sterilized saline that is 10 times the weight of the mixed preparation, and stir at room temperature wi...

Embodiment 3

[0027] Fresh eggs are washed, sterilized, and beaten to obtain 100kg of whole egg liquid. Add 1.0kg of salt, 0.005kg of sodium bisulfite, and 2kg of fructose syrup and stir evenly. Heat to 60°C while stirring, keep for 15 minutes to sterilize, and cool the egg liquid to 35° C., add 0.05 kg of Lactobacillus helveticus preparation and 0.1 kg of Luxie yeast preparation, and ferment at 30° C. for 2 hours. The fermented egg liquid is poured into the mould, heated by steam at 95°C for 30 minutes to denature and mature the egg liquid, take the egg base out of the mold, cut the egg base into small pieces of 3cm×2cm×0.8cm, and put the small pieces of egg The billets are erected and placed on a wooden perforated sieve with an interval of 5.0 cm between the billets. Mix the spores of Wutongqiao Mucor and Aspergillus niger at a ratio of 5:1 to prepare a mixed preparation, weigh 0.1 kg of the mixed preparation and add it to 20 times the weight of the mixed preparation in sterilized saline,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com