Preparation method and application of MEMS infrared light source

An infrared light source and infrared light technology, applied in the field of infrared light source, can solve problems such as high integration difficulty, high application cost, and difficulty in heat dissipation of the light source, and achieve the effects of reducing integration difficulty, improving generation efficiency, and ensuring thermal insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

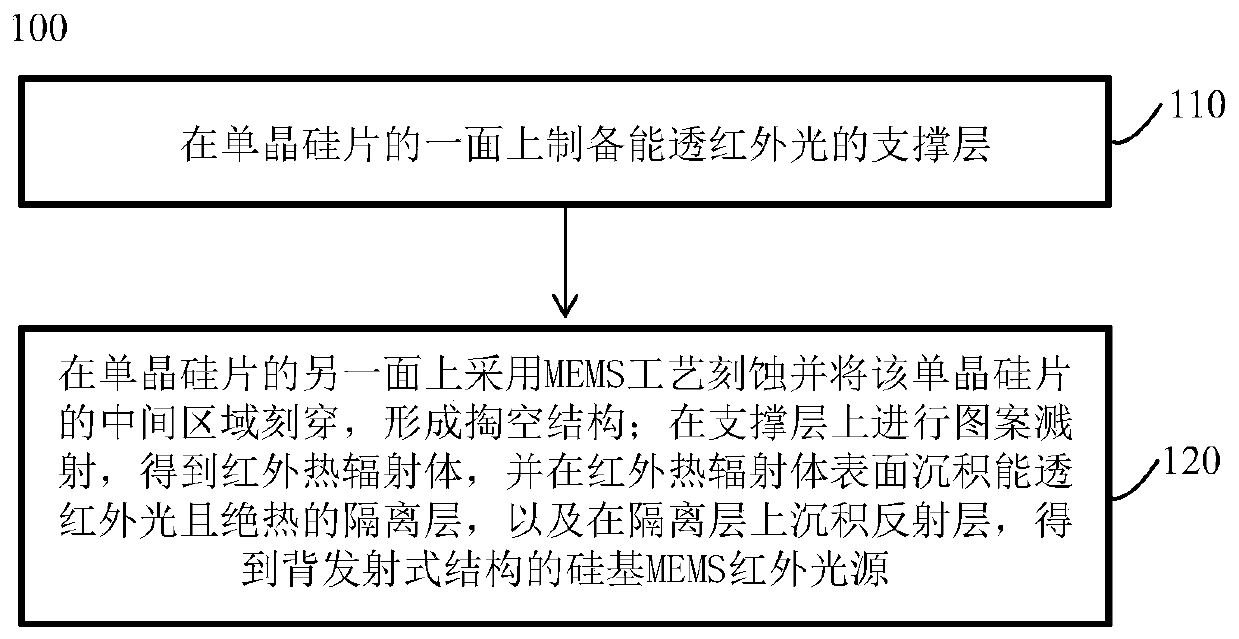

[0035] A preparation method 100 of a MEMS infrared light source, such as figure 1 shown, including:

[0036] Step 110, preparing a support layer capable of transmitting infrared light on one side of the single crystal silicon wafer;

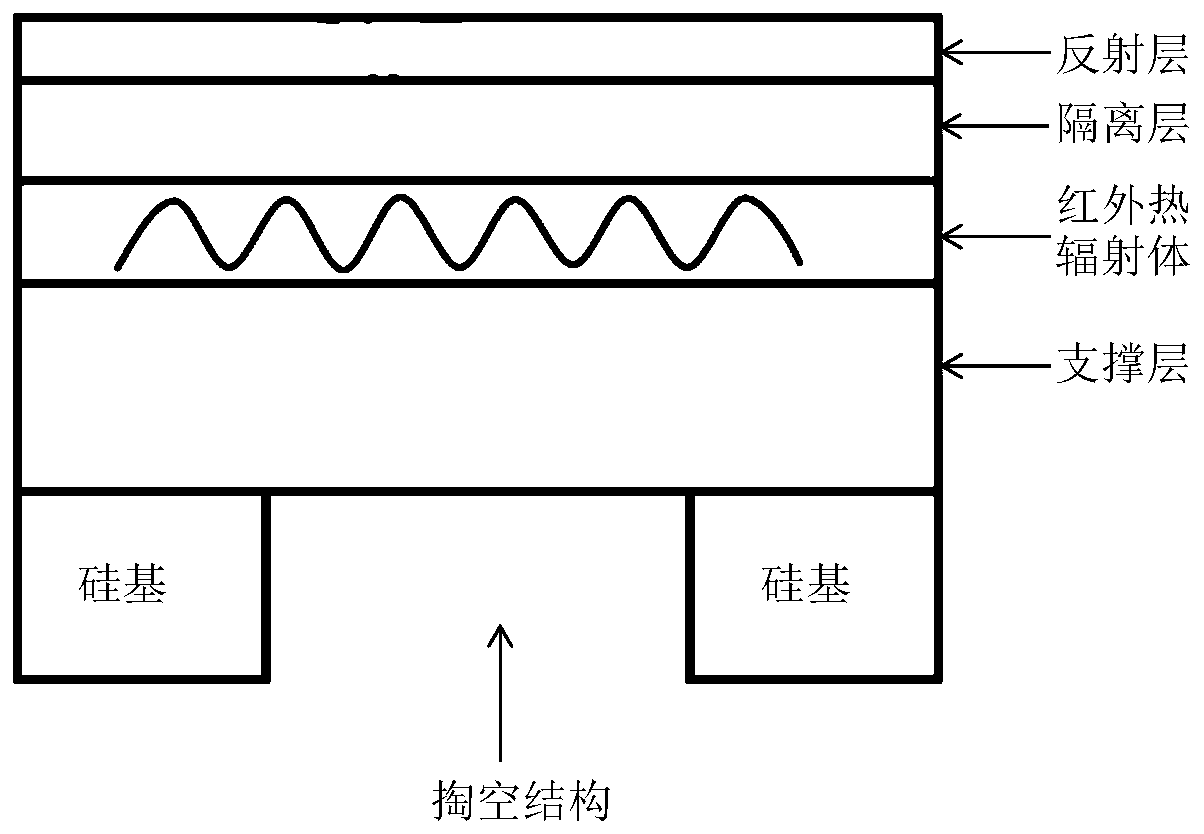

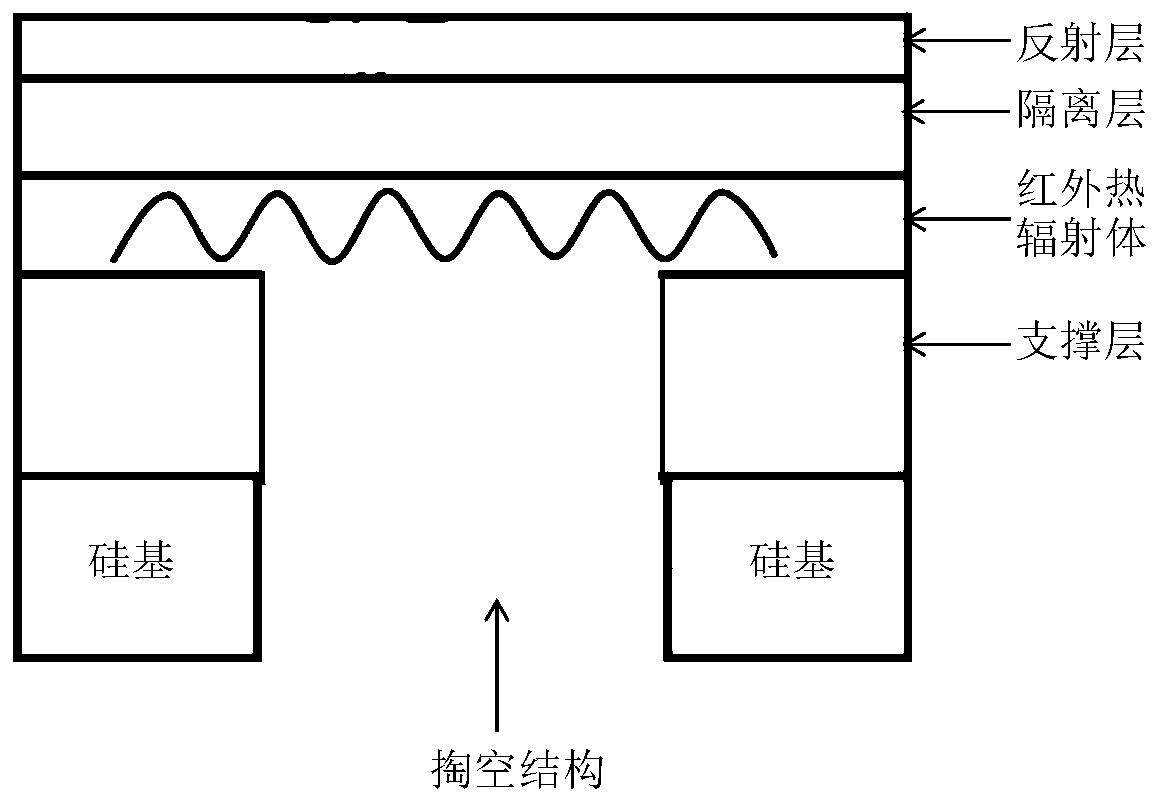

[0037] Step 120, using MEMS technology to etch the other side of the single crystal silicon wafer and carving through the middle area of the single crystal silicon wafer to form a hollow structure; performing pattern sputtering on the support layer to obtain an infrared heat radiator, And on the surface of the infrared heat radiator, an isolation layer capable of transmitting infrared light and heat insulation is deposited, and a reflective layer is deposited on the isolation layer to obtain a silicon-based MEMS infrared light source with a back-emitting structure.

[0038] It should be noted that in step 120, the MEMS process is used to etch to form a hollow structure and pattern sputtering on the support layer. There is no necessary sequence...

Embodiment 2

[0105] A MEMS infrared light source device, comprising: a MEMS infrared light source prepared by any one of the MEMS infrared light source preparation methods described in the first embodiment above, and a power supply electrically connected to the infrared heat radiator in the light source.

[0106] The heating wire (such as Pt) is used as the radiation source, the upper layer of silicon nitride is used as the isolation layer (which acts as a thermal insulation and isolates the heating wire and the reflective layer), and the gold layer is used as the reflective layer. The reflectivity of gold reaches 99%, which can almost completely reflect All the infrared light radiated by the heating wire is radiated from the cavity of the silicon on the back to form a back-emitting MEMS infrared light source. The prepared back-emitting MEMS infrared light source can not only reduce the loss of radiated light from black body radiation, but also enhance the intensity of the light source, and...

Embodiment 3

[0109] An infrared detection integrated system, comprising: a MEMS infrared light source device as described in the second embodiment above, and its corresponding back-end infrared receiving device, wherein, the edge of the hollowed out structure in the infrared light source device and the infrared receiving device Infrared light input port connection.

[0110] For example, the NDIR infrared gas sensor based on the non-dispersive infrared (Non-Dispersive Infra-Red, NDIR) absorption principle is based on the near-infrared spectrum selective absorption characteristics of different gas molecules, using the relationship between gas concentration and absorption intensity (Lambert-Beer’s law) A gas sensing device that identifies gas components and determines their concentrations. Current NDIR infrared gas sensors are usually composed of discrete components such as a light source, a gas chamber, and a detector. According to the NDIR measurement principle, the sensitivity, detection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com