Method for treating quenching wastewater in acrylonitrile production process

A technology of production process and treatment method, which is applied in the field of quenching wastewater treatment, can solve the problems of serious environmental pollution and high energy consumption, and achieve the effects of simple process, good technical effect, and easy industrialization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

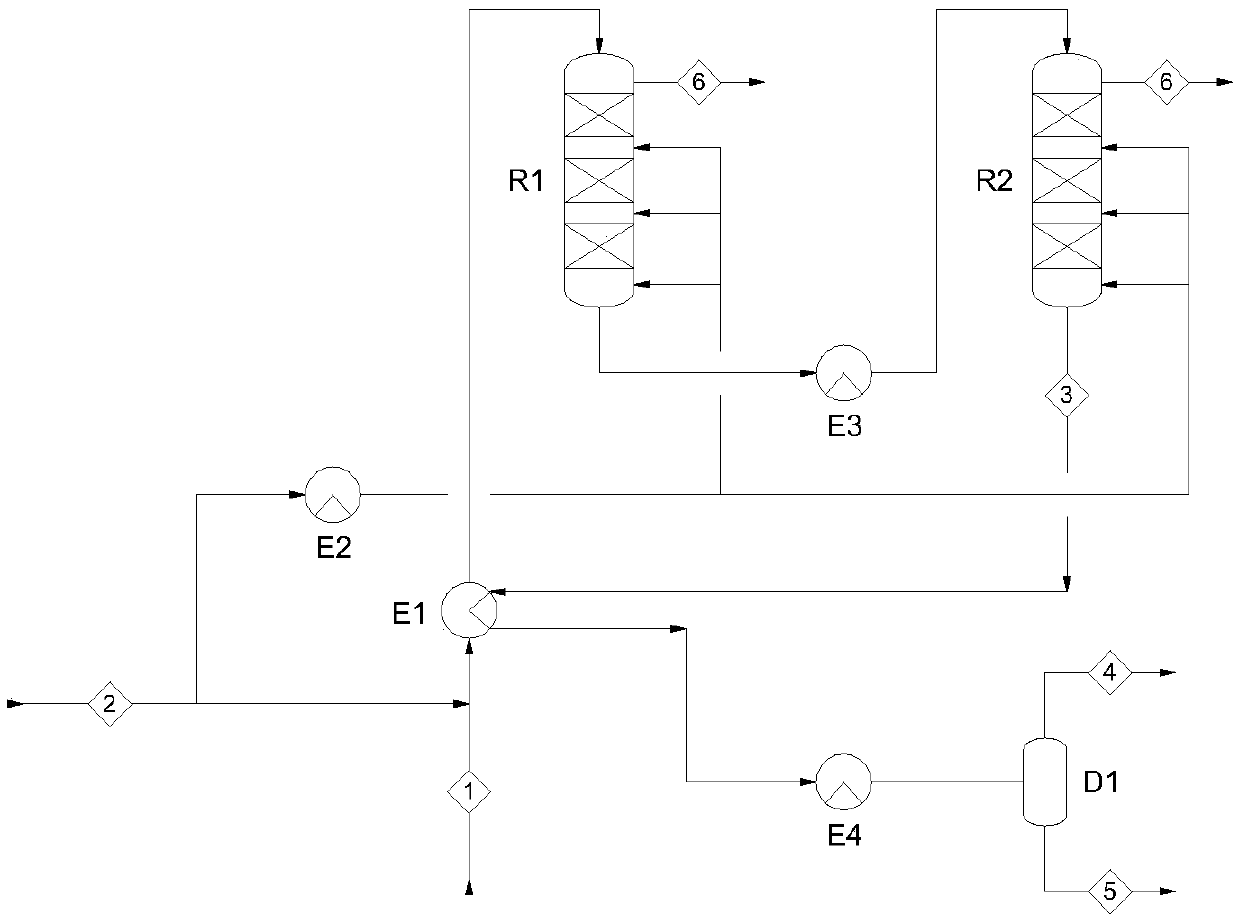

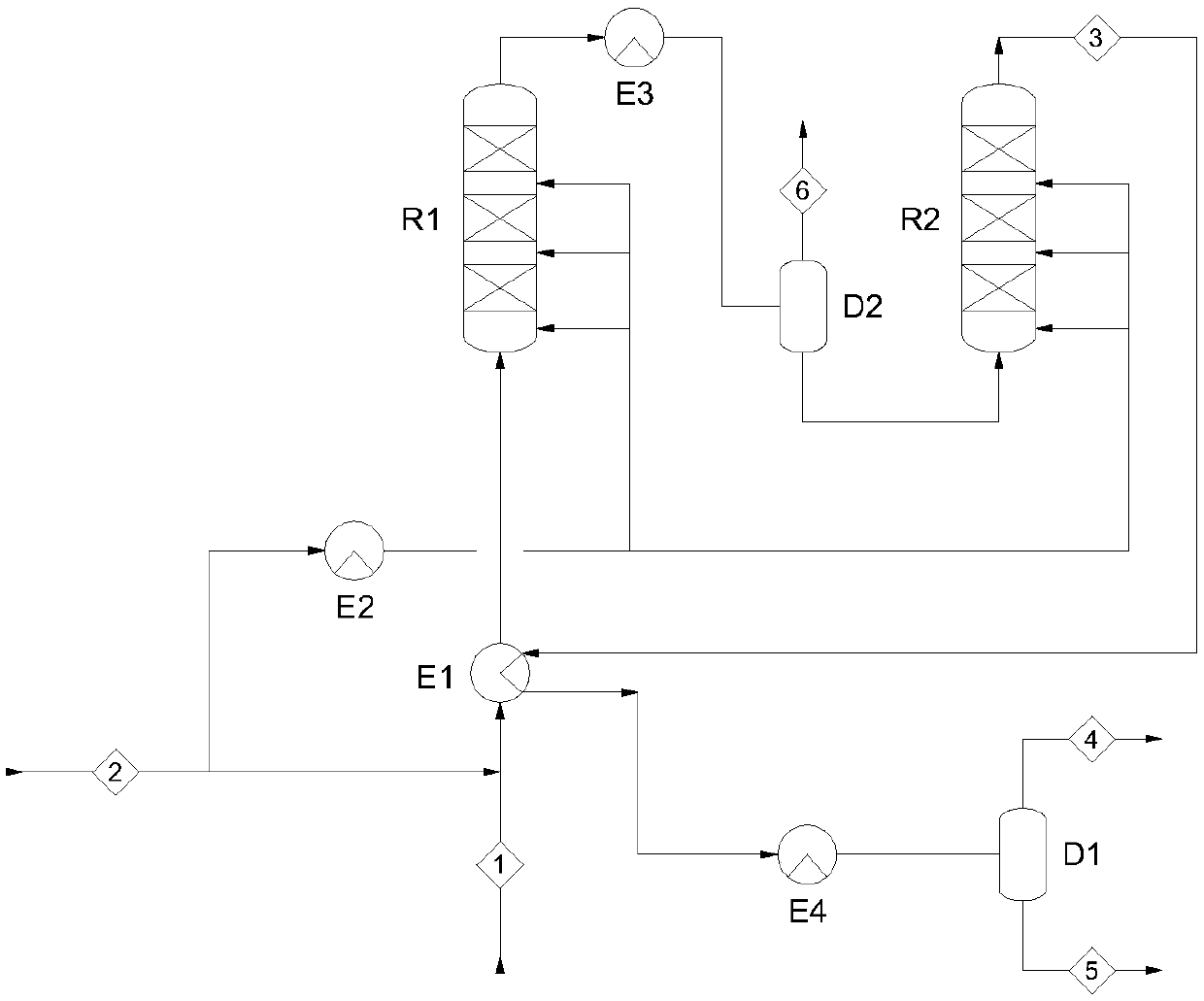

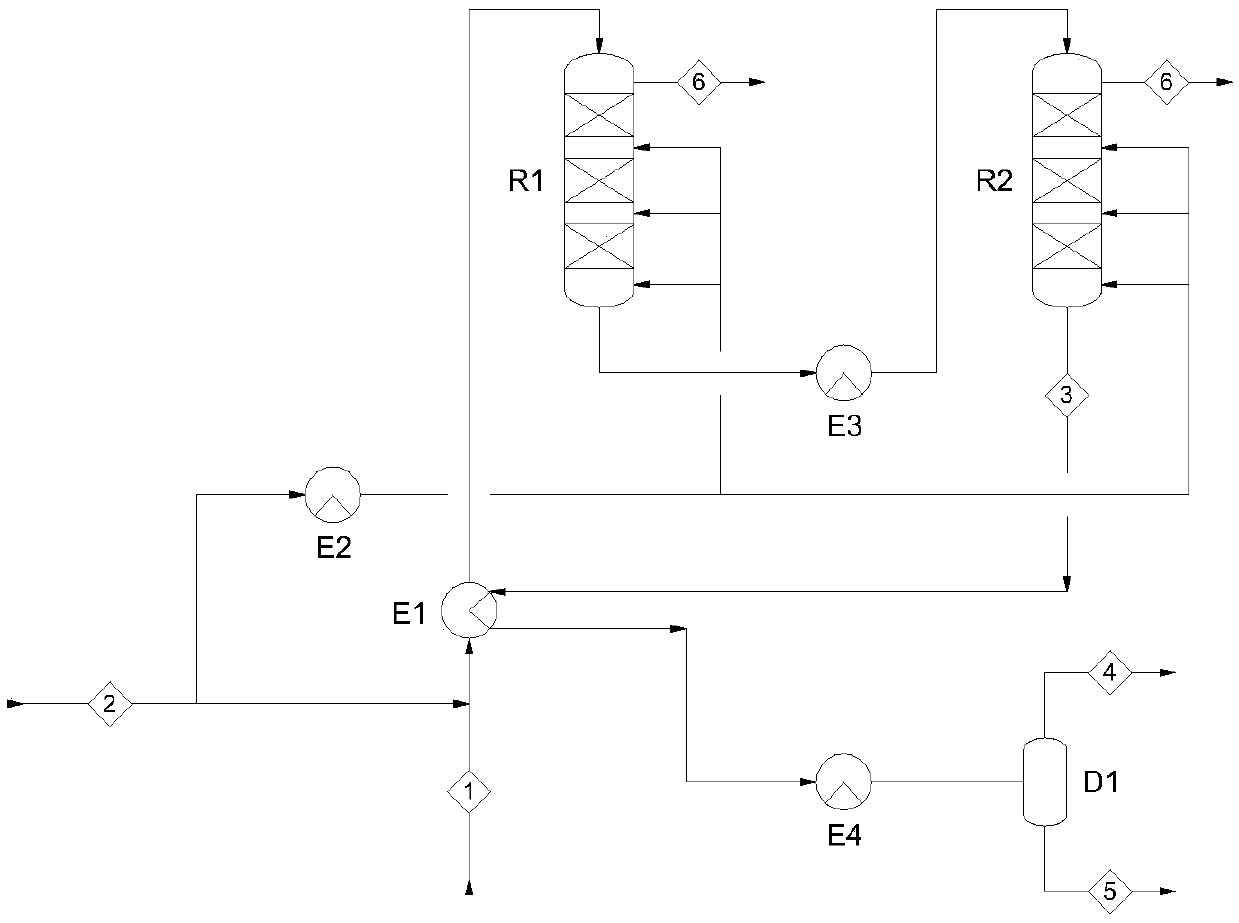

[0028] according to figure 1 As shown, the COD value of the feed quenching wastewater is 340295mg / L. The catalytic wet oxidation reaction zone includes 6 adiabatic fixed-bed reactors, and each reactor only includes 1 stage of catalyst bed, and each catalyst bed is filled with composite Metal oxide catalyst; total volume space velocity is 1.8h -1 , the inlet temperature of each reactor is 200°C, and the inlet pressure of the first reactor is 12.0MPaG; the oxygen-containing gas is oxygen, and the amount of oxygen is the theoretical oxygen consumption required based on the COD value of the feed quenched wastewater 1.3 times of that; the amount of gas entering from the inlet of the quenched waste water raw material is 10% of the total intake, and the amount of gas entering from the bottom of the catalyst bed of the first section to the sixth section is respectively 10% and 10% of the total intake. 12%, 14%, 16%, 18%, 20%; the COD removal rate of the obtained quenching wastewater ...

Embodiment 2

[0030] according to figure 1 As shown, the COD value of the feed quenching wastewater is 287831mg / L, and the catalytic wet oxidation reaction zone includes 5 adiabatic fixed-bed reactors. Only one stage of catalyst bed is included, and each catalyst bed is filled with composite metal oxide catalyst; the total volume space velocity is 1.2h -1 , the inlet temperature of each reactor is 210°C, and the inlet pressure of the first reactor is 10.5MPaG; the gas containing oxygen is oxygen, and the amount of oxygen is the theoretical oxygen consumption required based on the COD value of the feed quenched wastewater 1.2 times of that; the amount of gas entering from the inlet of the quenched waste water raw material is 5% of the total intake, and the amount of gas entering from the bottom of the catalyst bed of the first section to the seventh section is respectively 4% and 4% of the total intake 9%, 10%, 14%, 16%, 19%, 23%; the COD removal rate of the obtained quenching wastewater is...

Embodiment 3

[0032] according to figure 1 As shown, the COD value of the feed quenching wastewater is 87343mg / L, and the catalytic wet oxidation reaction zone includes 2 adiabatic fixed-bed reactors, and the first reactor includes 2 stages of catalyst beds and is filled with composite metal oxide catalysts. The second reactor includes 2 stages of catalyst beds and are filled with precious metal supported catalysts; the total volume space velocity is 0.8h -1 , the inlet temperature of each reactor is 220°C, and the inlet pressure of the first reactor is 8.0MPaG; the oxygen-containing gas is air, and the amount of air is sufficient to make the amount of oxygen contained in the feed quenched wastewater COD 1.4 times of the theoretical oxygen consumption required by the value meter; the amount of gas entering from the inlet of the quenched waste water raw material is 0% of the total intake, and the amount of gas entering from the bottom of the catalyst bed of the first section to the fourth se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com