Novel industrial wastewater treatment system

A technology for industrial wastewater and treatment systems, applied in water/sewage treatment, aerobic process treatment, natural water treatment, etc., can solve the problems of low investment cost and ammonia nitrogen pollution, and achieve low investment cost, good effluent quality, and environmental benefits. and significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

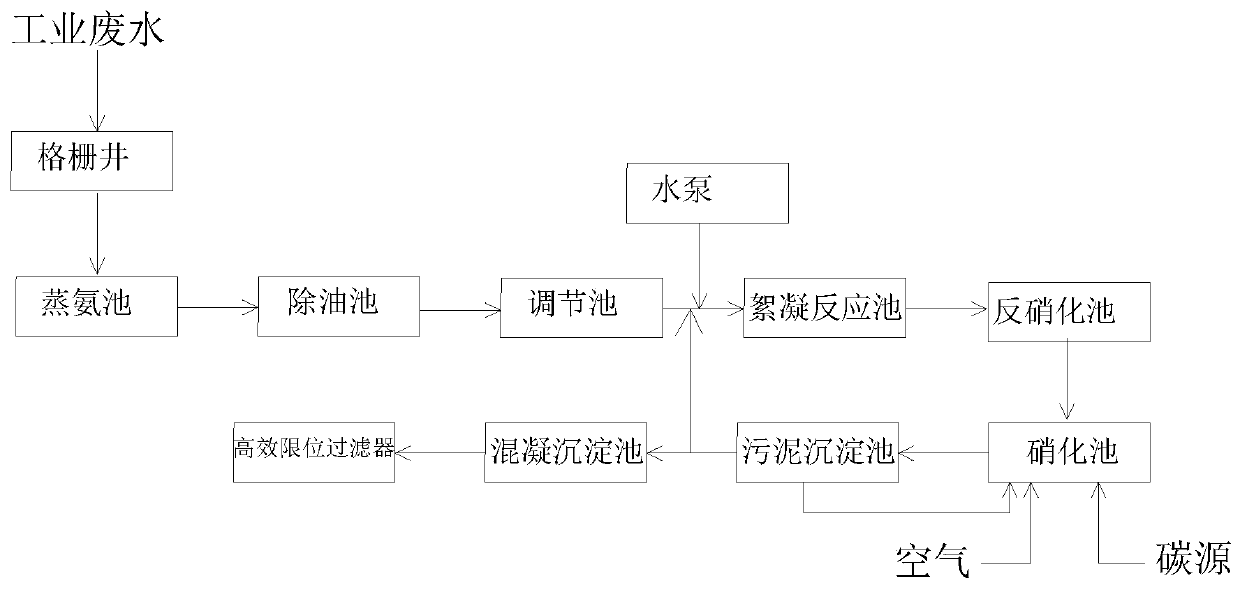

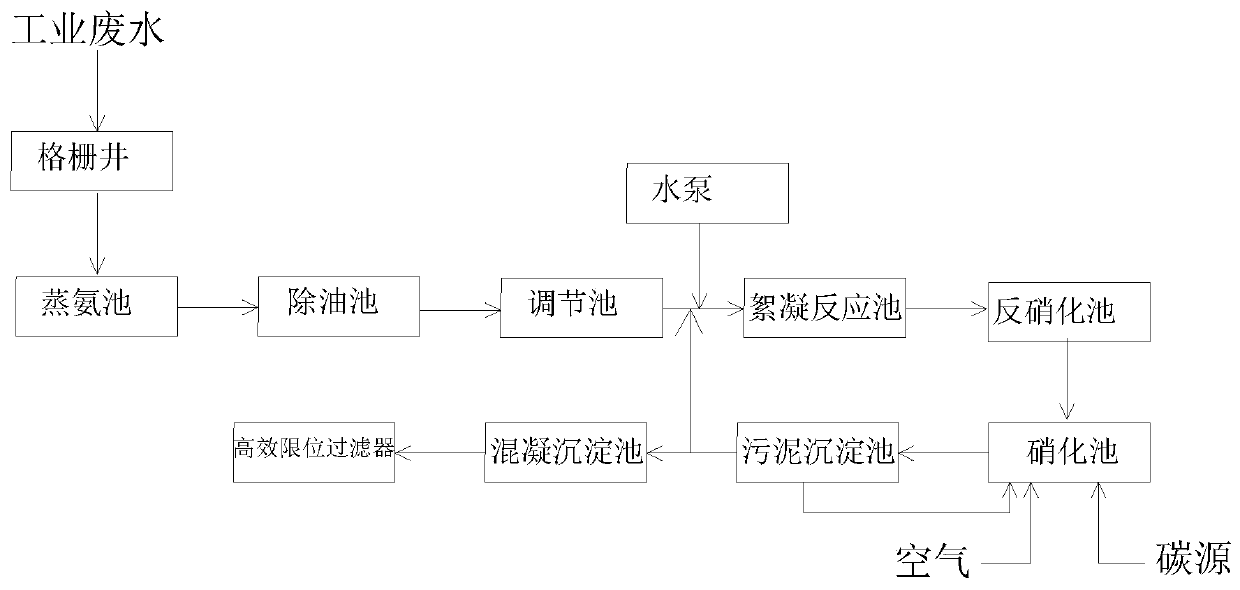

[0017] A new type of industrial wastewater treatment system, such as figure 1 As shown, it includes grid wells, ammonia distillation tanks, oil removal tanks, adjustment tanks, flocculation reactors, denitrification tanks, nitrification tanks, sludge sedimentation tanks, coagulation sedimentation tanks, and high-efficiency fiber filters that are connected in sequence through pipelines , wherein, a water pump is provided on the pipeline between the adjustment tank and the flocculation reactor.

[0018] The industrial waste water is collected to the waste water treatment station through the waste water pipe network. The waste water enters the grid well first, and a mec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com