Preparation method of acetaldoxime

An acetaldoxime and reaction technology, which is applied in the field of preparation of acetaldoxime, can solve the problems of waste acid discharge in wastewater, large amount of hydroxylamine salt, long reaction process, etc., and achieves high adsorption efficiency, short reaction process and good adsorption effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

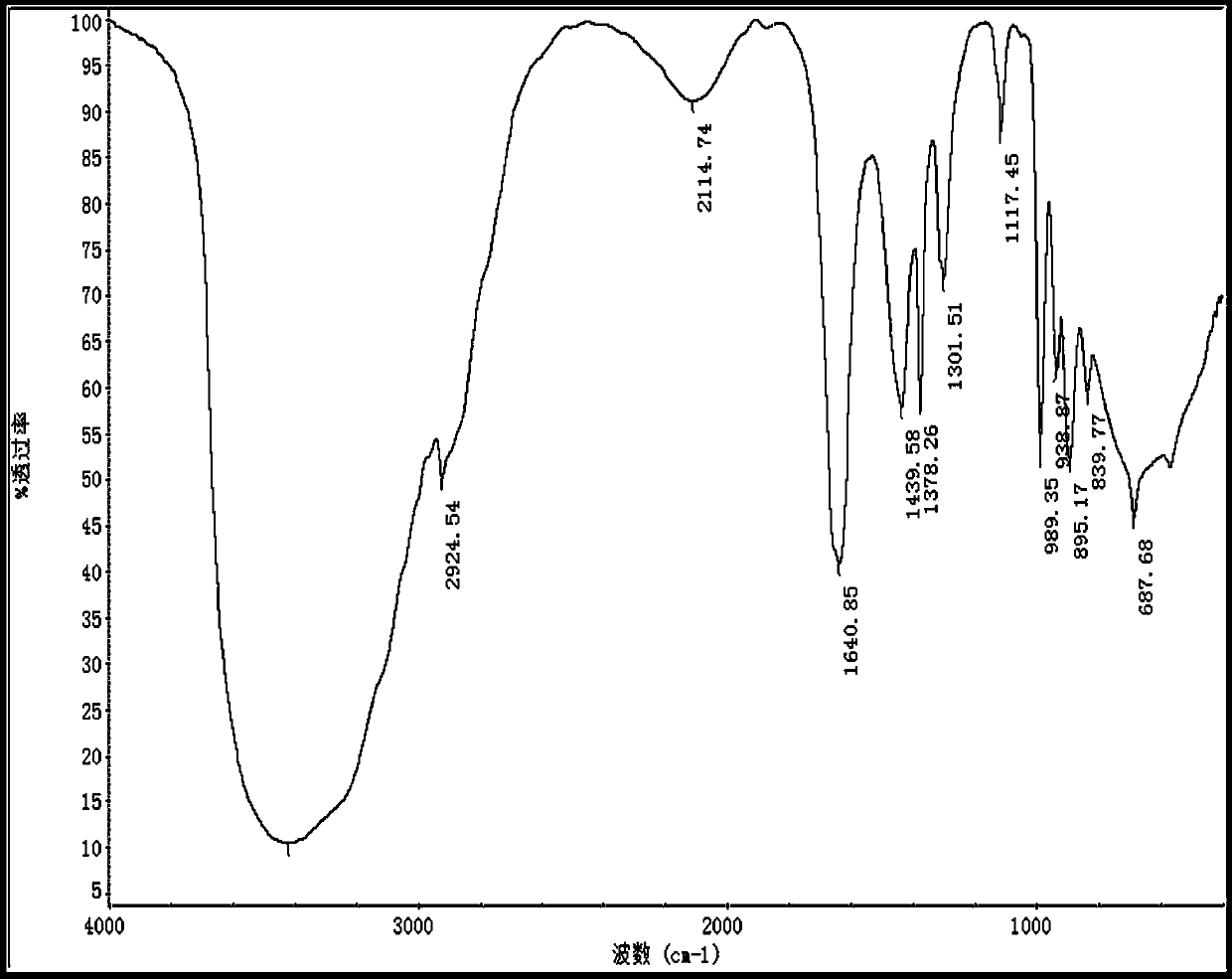

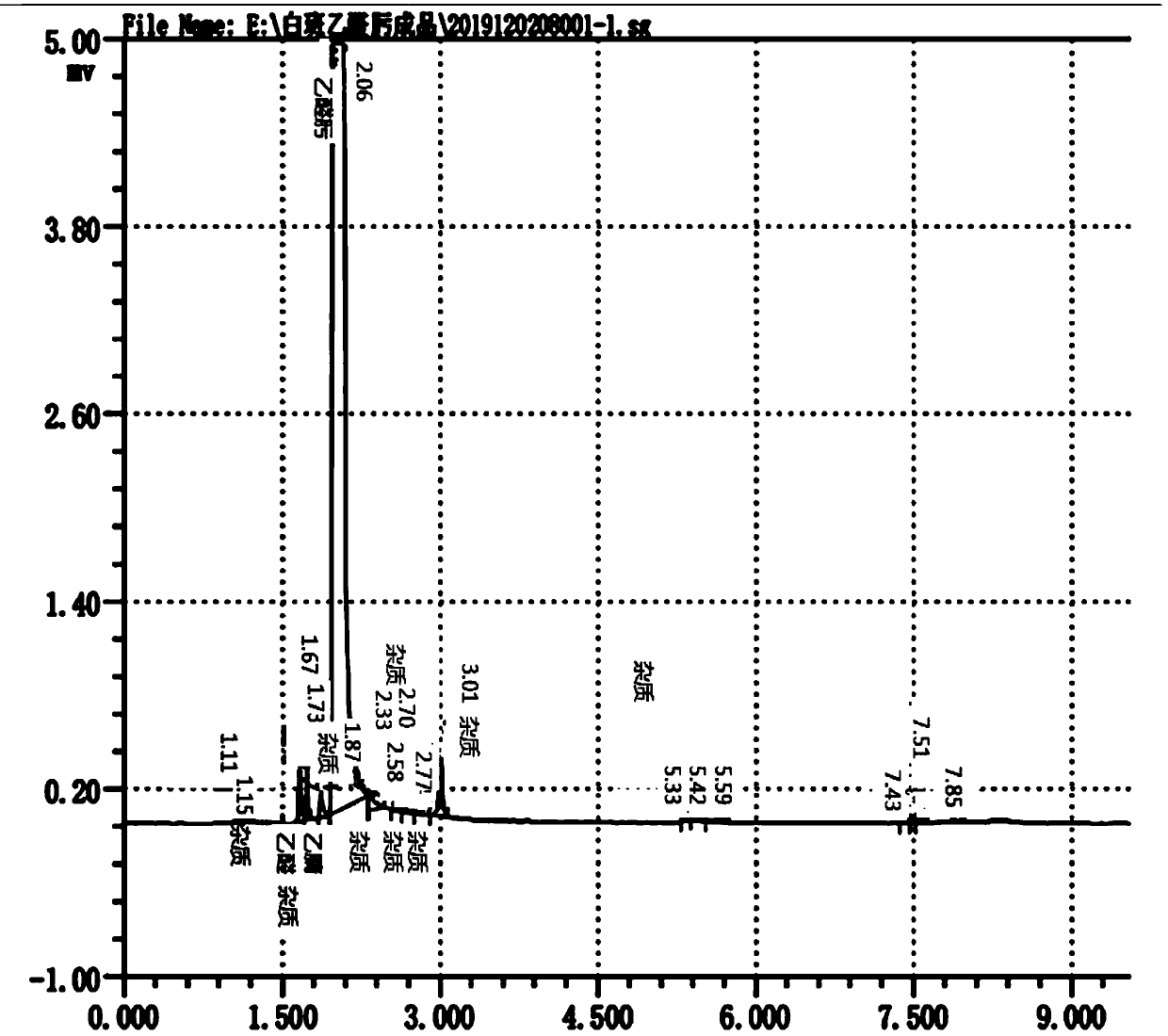

Image

Examples

Embodiment 1

[0025] A kind of preparation method of acetaldehyde oxime, its operation step is:

[0026] According to the number of parts by mass, 40-Kg hydroxylamine phosphate, 8.4Kg acetaldehyde and 260Kg water were added to the reactor, the temperature was controlled at 30°C, and the reaction mixture was obtained after 2 hours of reaction; the reaction mixture entered the stripping tower, and the organic matter and part Water is steamed from the top of the tower, and the purified inorganic liquid at the bottom of the tower is returned to the front system for recycling to make hydroxylamine phosphate; while the top liquid of the stripping tower enters the rectification system for separation and purification, and finally obtains a 47% acetaldehyde oxime aqueous solution Product; it is characterized in that described purification operation adopts a kind of graphene modified adsorbent packing adsorption column to adsorb organic impurities.

[0027] Described a kind of graphene modified adsor...

Embodiment 2

[0034] A kind of preparation method of acetaldehyde oxime, its operation step is:

[0035] According to the number of parts by mass, 50Kg hydroxylamine phosphate, 10.5Kg acetaldehyde and 320Kg water were added to the reactor, the temperature was controlled at 50°C, and the reaction mixture was obtained after 1 hour of reaction; The top of the tower is steamed, and the purified inorganic liquid at the bottom of the tower is returned to the former system for recycling to make hydroxylamine phosphate; while the top liquid of the stripping tower enters the rectification system for separation and purification, and finally obtains a 50% acetaldehyde oxime aqueous solution product; It is characterized in that the purification operation adopts a graphene-modified adsorbent packing adsorption column to adsorb organic impurities.

[0036] Described a kind of graphene modified adsorbent filler, its preparation method is as follows:

[0037] According to the mass parts, under the protect...

Embodiment 3

[0043] A kind of preparation method of acetaldehyde oxime, its operation step is:

[0044] According to the mass parts, 60Kg of hydroxylamine phosphate, 13.2Kg of acetaldehyde and 420Kg of water were added to the reactor, the temperature was controlled at 80°C, and the reaction mixture was obtained after 2 hours of reaction; The top of the tower is steamed, and the inorganic liquid purified at the bottom of the tower is returned to the front system for recycling to make hydroxylamine phosphate; while the top liquid of the stripping tower enters the rectification system for separation and purification, and finally obtains a 52% acetaldehyde oxime aqueous solution product; It is characterized in that the purification operation adopts a graphene-modified adsorbent packing adsorption column to adsorb organic impurities.

[0045] Described a kind of graphene modified adsorbent filler, its preparation method is as follows:

[0046] According to the mass parts, under nitrogen protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com