Wear-resistant welded steel pipe and preparation process thereof

A technology of welding steel pipes and wear resistance, which is applied in the field of steel pipe processing, can solve the problems of steel pipe wall thickness reduction, shorten the service life of steel pipes, wear and tear, etc., and achieve the effect of improving wear resistance and enhancing adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

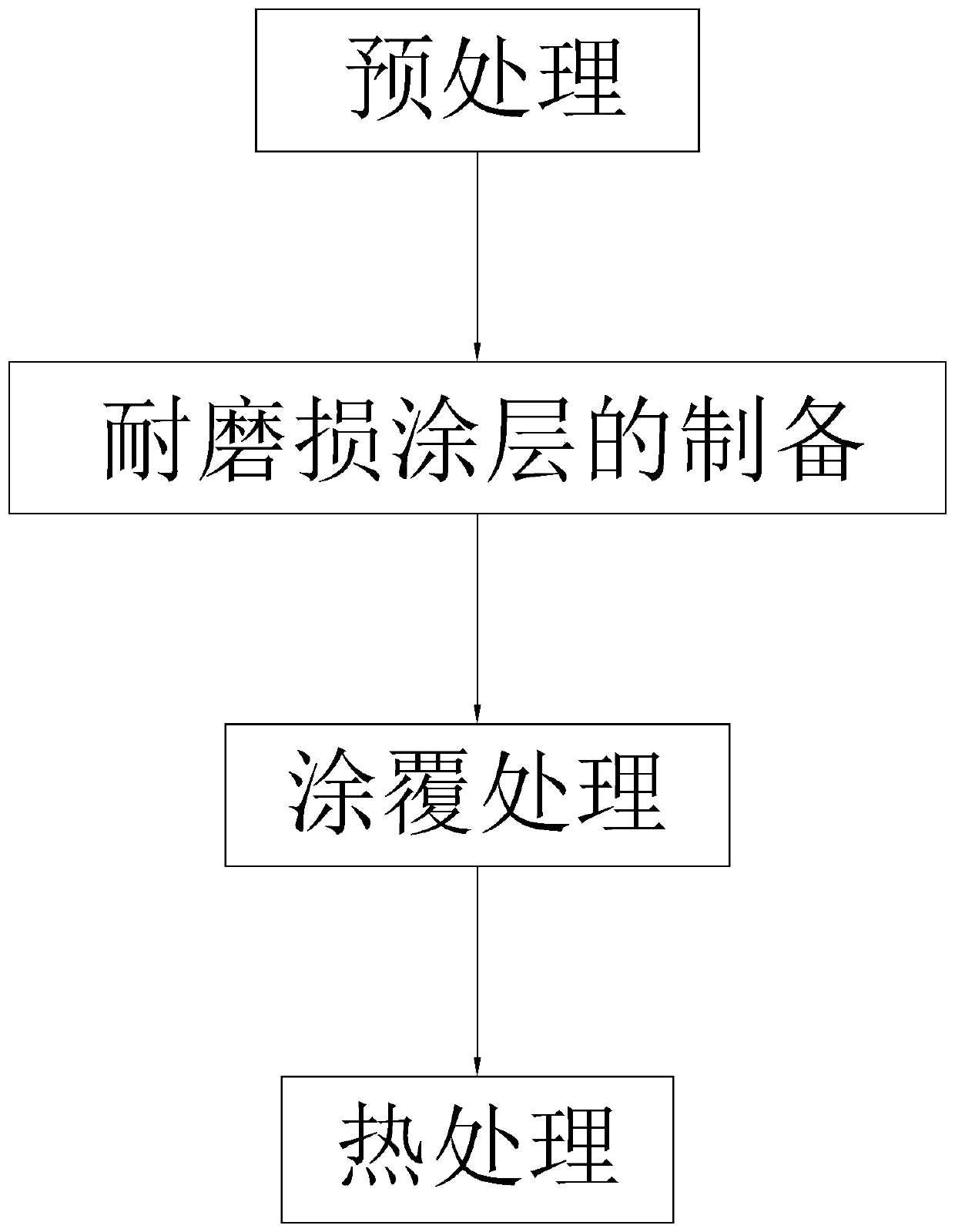

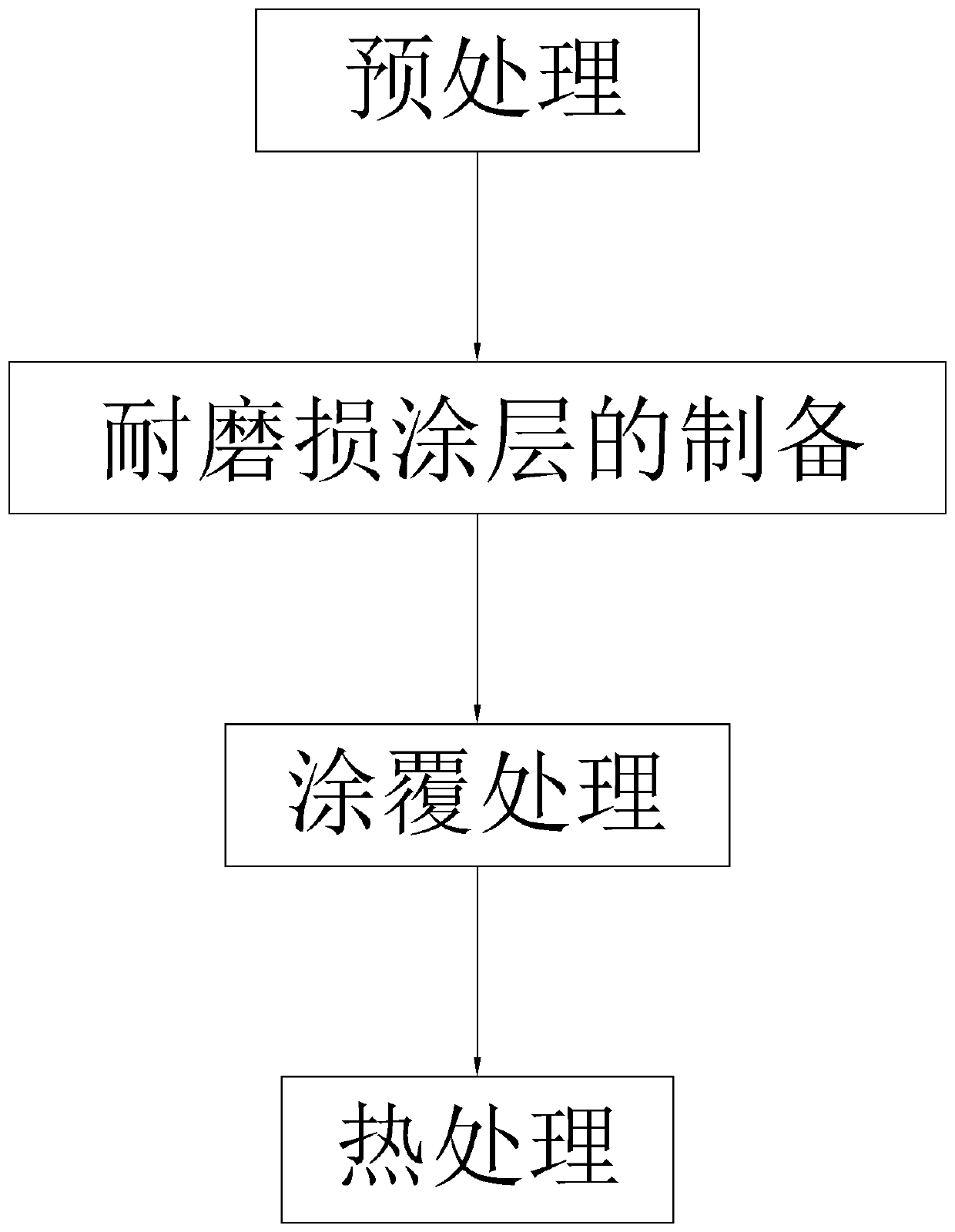

[0045] refer to figure 1 , is a preparation process of a wear-resistant welded steel pipe disclosed by the present invention, comprising the following steps:

[0046] S1. pretreatment; use trichlorotrifluoroethane that accounts for less than 4% of the total cleaning agent as the main component of the cleaning agent, and the rest is water to prepare the cleaning agent to clean the surface of the steel pipe;

[0047]S2. Preparation of wear-resistant coating; weigh required components, mix malein rosin, propylene alcohol and acetone, then add zinc oxide, stir and reflux at a constant temperature of 180°C for 5h, and then Add epoxy resin and compatibilizer, and react at a temperature of 135°C for 3 hours to obtain a mixture; lower the temperature to 55°C, and then add montmorillonite and 4-ethylphenylamine to Malay In the mixture of rosin, acrylic alcohol and epoxy resin, stir for 35 minutes; then add toluene diisocyanate, then raise the temperature to 115°C, react with zinc oxid...

Embodiment 2

[0052] refer to figure 1 , is a preparation process of a wear-resistant welded steel pipe disclosed by the present invention, comprising the following steps:

[0053] S1. pretreatment; use trichlorotrifluoroethane that accounts for less than 4% of the total cleaning agent as the main component of the cleaning agent, and the rest is water to prepare the cleaning agent to clean the surface of the steel pipe;

[0054] S2. Preparation of wear-resistant coating; weigh the required amount of components, mix maleic rosin, propylene alcohol and acetone, then add zinc oxide, stir and reflux at a constant temperature of 160 ° C for 4 hours, and then Add epoxy resin and compatibilizer, react at a temperature of 120°C for 2 hours to obtain a mixture; lower the temperature to 50°C, and then add the evenly mixed montmorillonite and 4-ethylphenylamine to the In the mixture of rosin, acryl alcohol and epoxy resin, stir for 30 minutes; then add toluene diisocyanate, then raise the temperature...

Embodiment 3

[0059] refer to figure 1 , is a preparation process of a wear-resistant welded steel pipe disclosed by the present invention, comprising the following steps:

[0060] S1. pretreatment; use trichlorotrifluoroethane that accounts for less than 4% of the total cleaning agent as the main component of the cleaning agent, and the rest is water to prepare the cleaning agent to clean the surface of the steel pipe;

[0061] S2. Preparation of wear-resistant coating; weigh the required amount of components, mix malein rosin, propylene alcohol and acetone, then add zinc oxide, stir and reflux at a constant temperature of 190 ° C for 6 hours, and then Add epoxy resin and compatibilizer, and react at a temperature of 140°C for 3 hours to obtain a mixture; lower the temperature to 60°C, and then add the evenly mixed montmorillonite and 4-ethylphenylamine to the In the mixture of rosin, acryl alcohol and epoxy resin, stir for 40 minutes; then add toluene diisocyanate, then raise the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com