Coal water slurry gasification fine ash treatment system and process

A treatment system, coal-water slurry technology, applied in the field of coal chemical industry, to achieve the effect of increasing ash output speed, stable equipment operation and good heat transfer performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

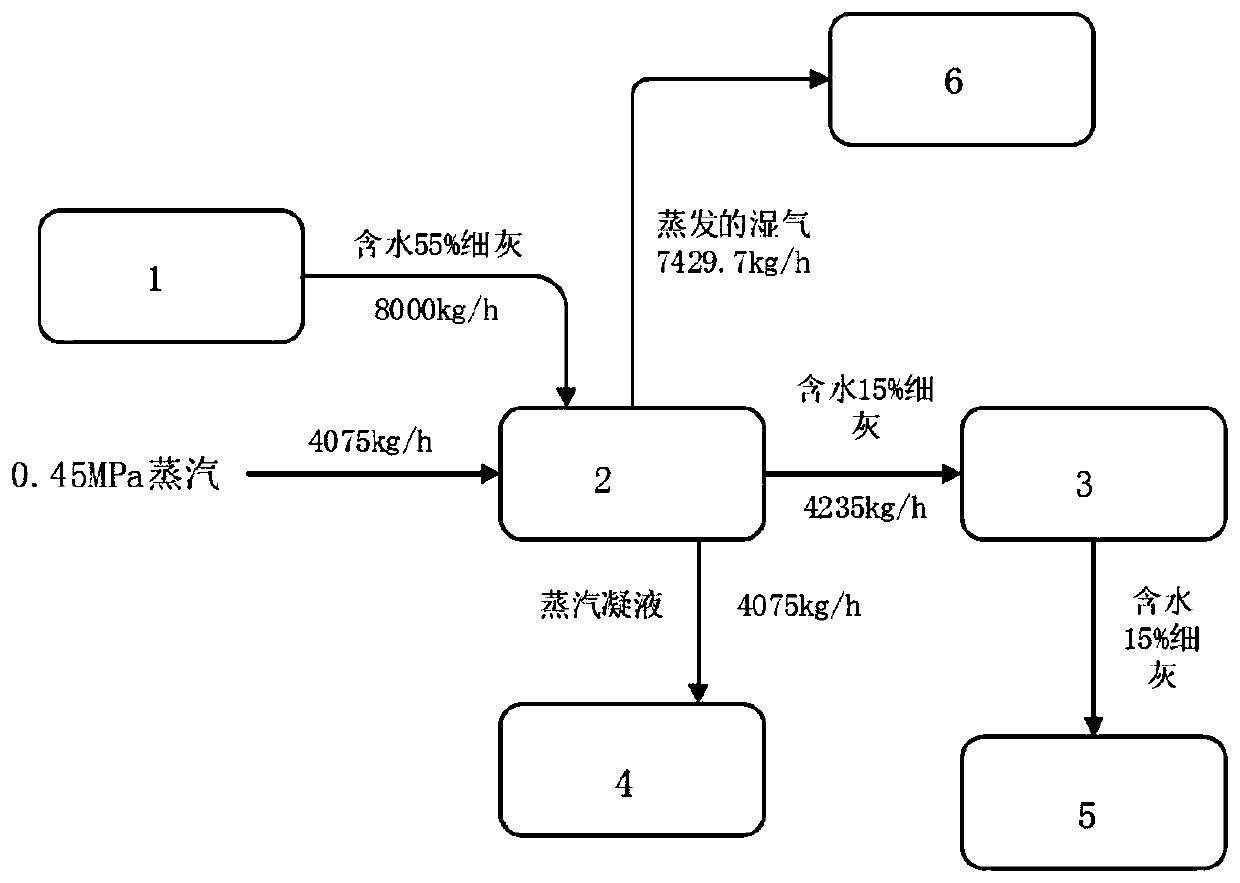

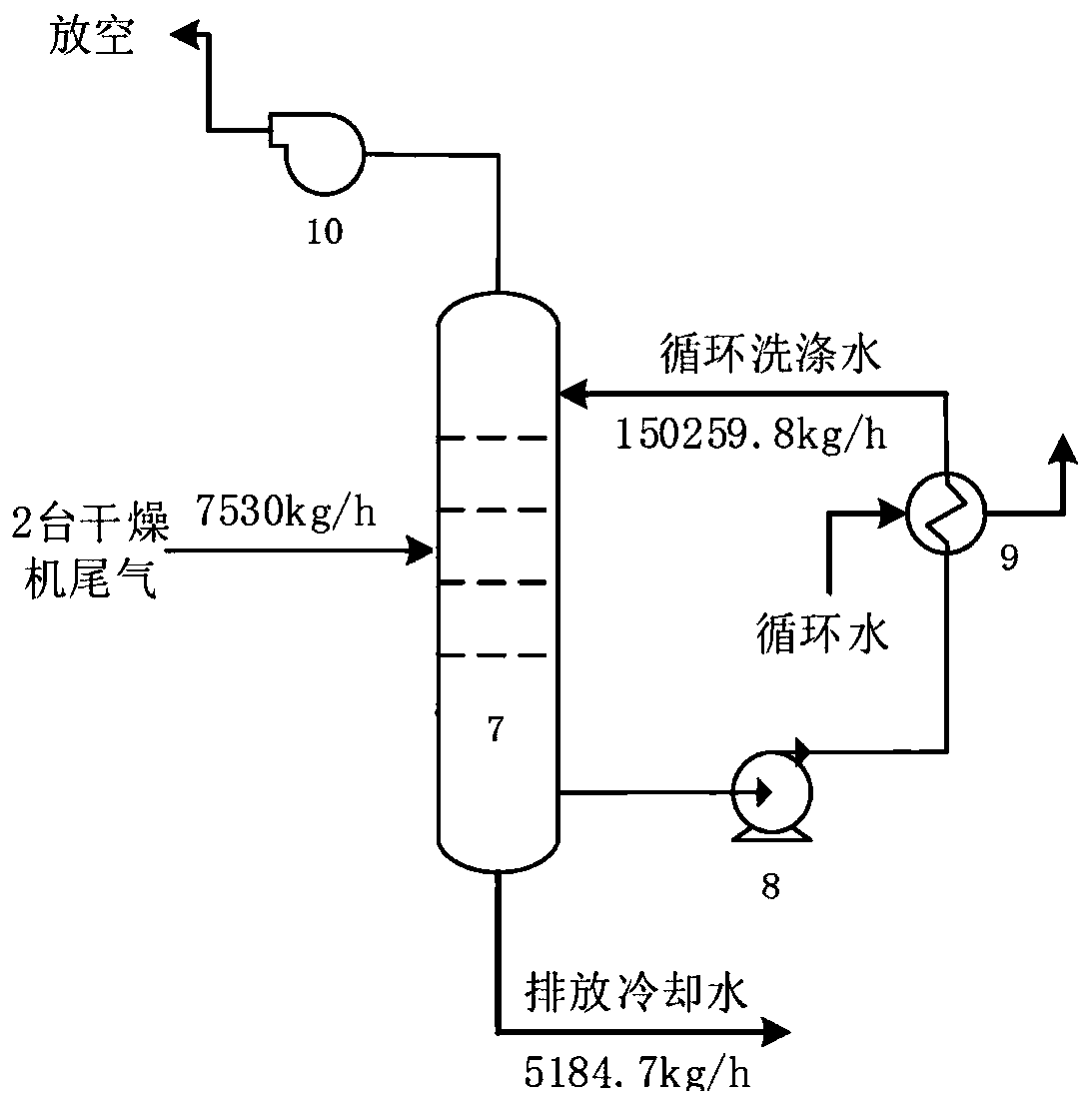

[0060] use Figure 1-5 In the gasification fine ash treatment system and process shown, the gasification fine ash filter cake with a moisture content of 55% from the upstream vacuum filter is 8000kg / h, and enters the inside of the dryer through the rotary valve at the feed port of the dryer for drying. After drying, the gasified fine ash powder 4235kg / h with a moisture content of 15% enters the downstream screw conveyor through the rotary valve at the outlet of the dryer, and is transported to the fine ash mixing device, where it is mixed with boiler coal and sent to the circulation Fluidized bed boiler for co-firing.

[0061] The disc-type steam dryer is used to dry the gasification fine ash filter cake as the heat medium is steam, and the steam is adjusted to the required pressure through the regulating valve and enters the jacket and the rotating shaft of the dryer to heat the material, using 0.45MPa low-pressure steam When the flow rate of added steam is 4075kg / h, the ste...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap