Method for tanning leather by external electric field

A technology of applied electric field and leather, applied in small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather hide/fur chemical treatment, chemical treatment before tanning, etc., can solve the problem of low shrinkage temperature and fracture of leather Problems such as poor elongation, limitation of chrome-free tanning method, etc., to achieve good tanning effect, low cost and improve tanning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

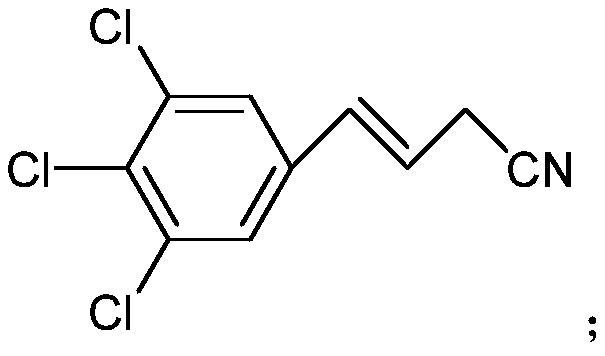

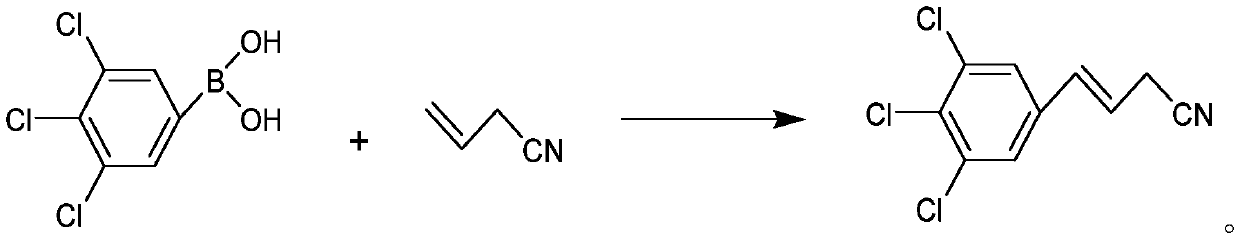

[0029] The preparation method of the (E)-4-(3,4,5-trichlorophenyl)but-3-enenitrile is:

[0030] At room temperature, 150 mmol (3,4,5-trichlorophenyl)boronic acid, 100 mmol 3-butenenitrile, 10 mmol catalyst palladium acetate, 5 mmol 2,2'-bipyridine, 250 mmol oxidant silver acetate and 600 mmol trifluoroacetic acid were added to Stir and mix in a reaction vessel with 20ml of solvent tetrahydrofuran, mix evenly, and react at a temperature of 90°C for 25 hours to obtain (E)-4-(3,4,5-trichlorophenyl ) but-3-enenitrile; Productive rate is 83.7%;

[0031] characterizing data

[0032] 1 H NMR (400MHz, CDCl 3 )δ7.06(s,2H),6.52-6.49(m,1H),6.25-6.21(m,1H),3.02(s,2H); 13 C NMR (100MHz, CDCl 3 )δ141.8, 135.7, 132.1, 129.8, 125.3, 121.4.117.1, 20.3;

[0033] Its reaction formula is

[0034]

Embodiment 2

[0036] A method for tanning leather with an external electric field, comprising the following steps: the amount of additives in each process is based on the quality of acid leather

[0037] Step 1: Add 100% deionized water and 8% sodium chloride into the drum, rotate for 20-30min, then add acid skin, continue to rotate for 20min, then adjust the pH of the system to 7.0-7.5, then rotate for 50min, control dry;

[0038] Step 2: Add 4% organic chlorine tanning agent, 0.4% cotanning agent and 100% deionized water into the drum, rotate at 32°C for 3 hours, and then perform the first tanning at 40°C , the tanning time is 4h, after the tanning is finished, control the drying;

[0039] Step 3: Add 100% deionized water into the drum, then adjust the pH of the system to 2.5-3.0 with a 10% sulfuric acid aqueous solution, and then rotate for 60 minutes; then add 2% zirconium tanning to the drum 15% sodium bicarbonate solution to adjust the pH of the system to between 5.5-6.0, and rotate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com