Comprehensive recovery process for difficult-to-separate copper-lead-zinc mixed concentrate

A technology of mixing concentrate, separation and recovery, applied in photography process, wet separation, solid separation and other directions, can solve the problems of ineffective separation and affecting the economic benefits of enterprises.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

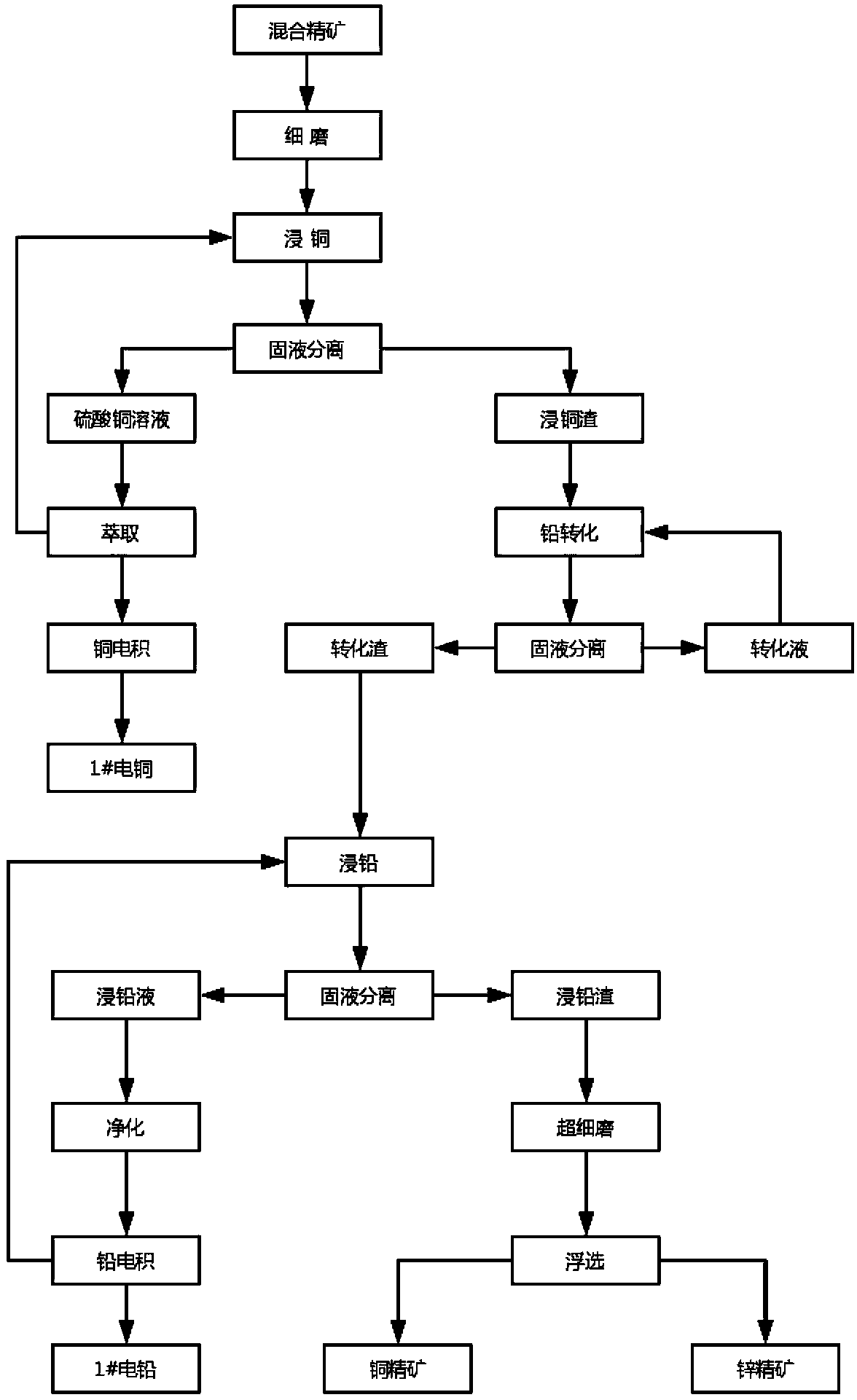

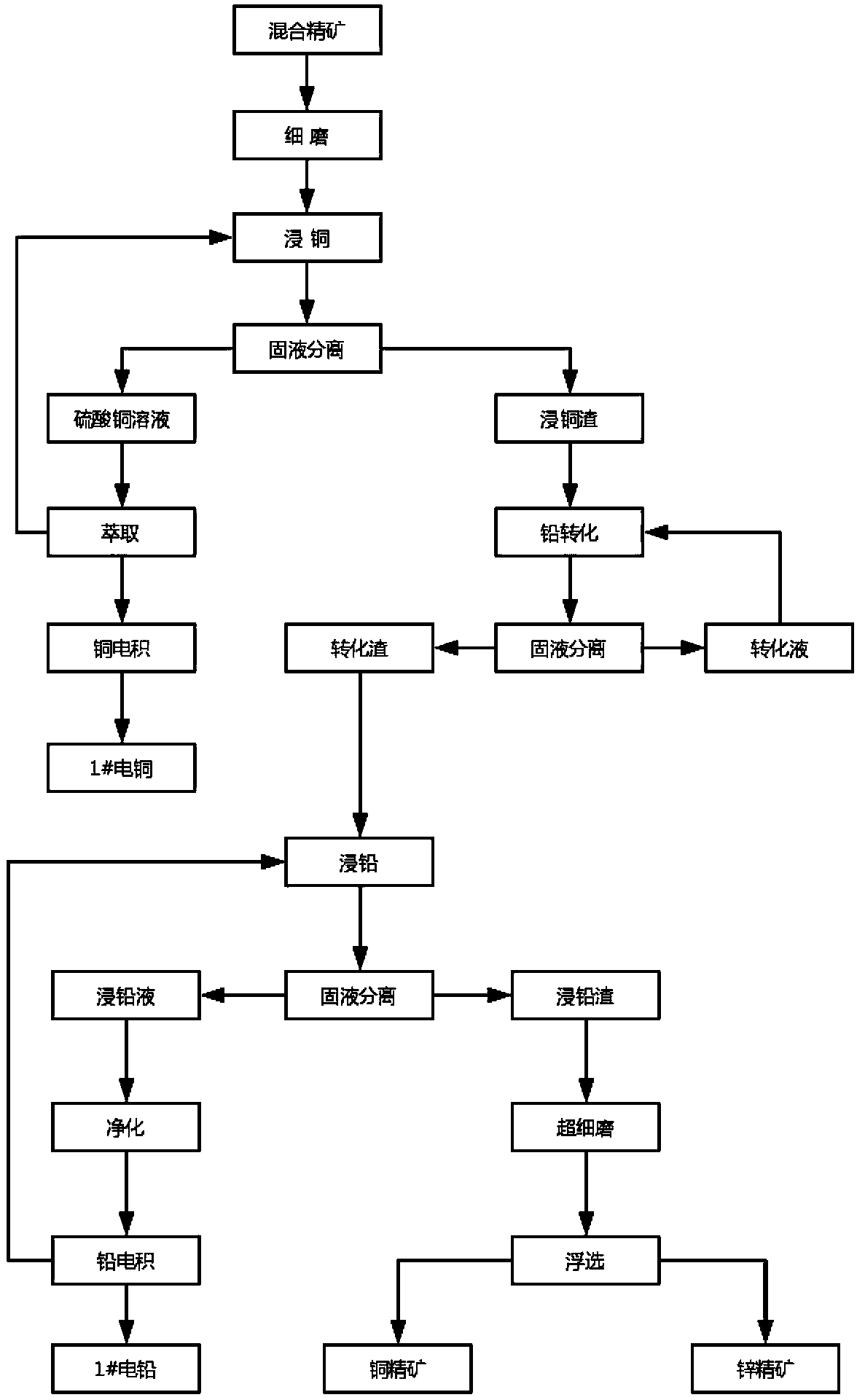

Image

Examples

Embodiment 1

[0024] A company in Shijiazhuang, Hebei uses cyanide tailings to produce gold, silver, copper, lead, and zinc mixed fine powder (the grades of gold, silver, copper, lead, and zinc are 5g / t, 300g / t, 3wt%, 20wt%, respectively. 15wt% hard-to-separate copper-lead-zinc mixed concentrate) because its nature is hard-to-separate fully sulfide gold-silver-copper-lead-zinc mixed concentrate, so there is no need for acid leaching-extraction-electrodeposition of the copper oxide part, and all subsequent processes are all match. After the raw materials are finely ground, the -200 mesh is greater than 95%, the pulping concentration is 15wt%, and the conversion agent and activator are added to enter the ammonia conversion process of lead elements. The specific conditions are: at a temperature of 52°C, the reaction time is 5-10 hours, the conversion agent is ammonium bicarbonate, and the catalyst is sodium lauryl sulfate. Based on the mixed concentrate, the addition amount of the conversion a...

Embodiment 2

[0027] A large state-owned enterprise in Tibet is currently producing refractory copper-lead-zinc mixed concentrates. The grades of gold, silver, copper, lead and zinc are 3g / t, 500g / t, 12wt%, 15wt%, 5wt% refractory Copper-lead-zinc mixed concentrates, such as figure 1 As shown, now the pulp concentration is 70wt% and finely ground to -200 mesh above 95%, then add water and 30g / L sulfuric acid and stir at 100 rpm for 30 minutes to leaching copper oxide, so that the concentration of the concentrate is 25wt%, and the pH of the pulp =2, solid-liquid separation to obtain copper sulfate solution and copper leaching slag, the copper sulfate solution is extracted, enriched and purified, and then enters the wet electrowinning process of copper. The specific conditions: the electrowinning solution contains 150 g / L of sulfuric acid and 50 g of copper ions / L, cell voltage 2 V, current density 240 A / m 2 , to produce the national standard 1# electrodeposited copper; the residual extracti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com