Method for preparing impregnated MM type cathode through microwave sintering

A microwave sintering and impregnation technology, which is applied in cathode manufacturing, cold cathode manufacturing, electrode system manufacturing, etc., can solve the problem that the emission current density of tungsten-iridium alloy cathode cannot meet the high current density, etc., and achieve fine grains and high-intensity emission. , the effect of high emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

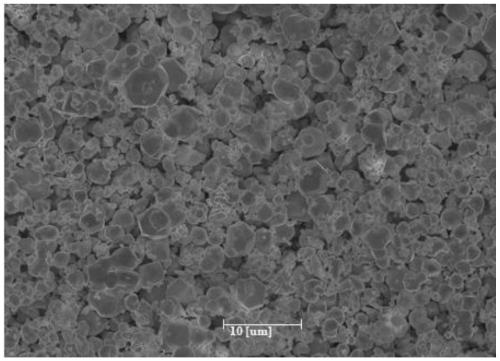

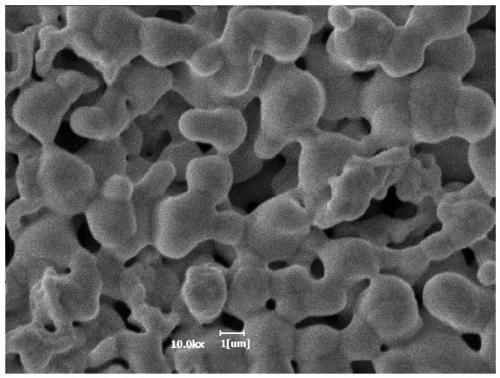

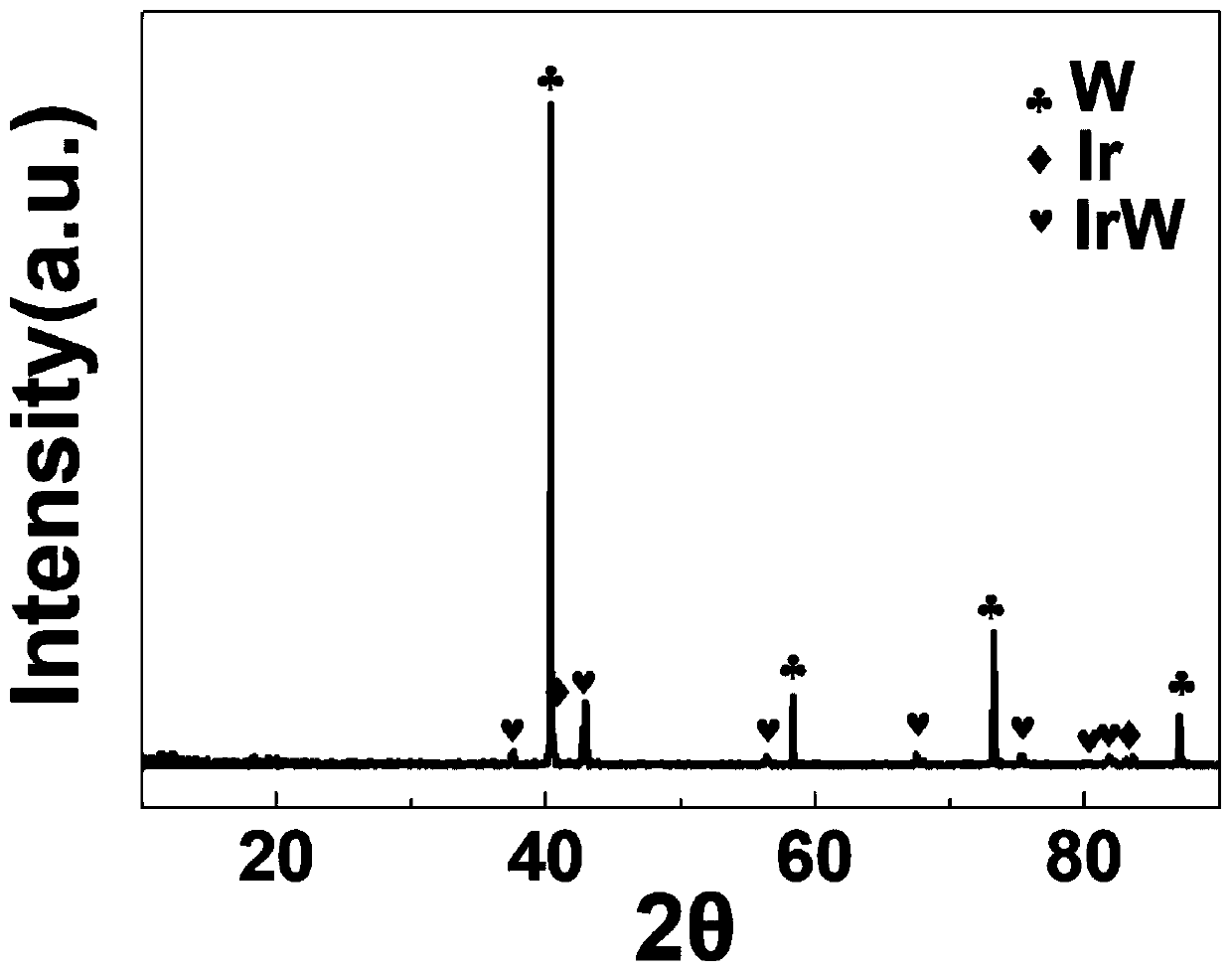

[0025] (1) Take 10g of micron-sized W powder (2.3μm) and 10g of micron-sized Ir powder (5μm), put them into crucibles respectively, and anneal at 1000°C for 1h in a tube furnace filled with hydrogen to ensure the original powder purification.

[0026] (2) According to the mass ratio of 15% Ir and 85% W, the above-mentioned powders were weighed and mechanically mixed and ground respectively, and passed through a 200-mesh sieve after being uniformly mixed to ensure the uniformity of the particle size of the mixed powder. Take a small amount of mixed powder, and use a stainless steel mold to cold press at a pressure of 4.0-7.0t / cm 2 Within the range, it is pressed into a green body with a diameter of 3mm and a height of 1.2-2mm.

[0027] (3) the green compact that step (2) is pressed is put into Al 2 o 3 In the crucible, they are placed together in a cavity surrounded by zirconia balls with a diameter of 3 mm as the auxiliary heat material, and are heated in argon-hydrogen (8%...

Embodiment 2

[0032] (1) Take 10g of micron-sized W powder (2.3μm) and 10g of micron-sized Ir powder (5μm), put them into crucibles respectively, and anneal at 1000°C for 1h in a tube furnace fed with hydrogen to ensure the original powder purify.

[0033] (2) According to the mass ratio of 20% Ir and 80% W, the above-mentioned powders were weighed, mechanically mixed and ground, and passed through a 200-mesh sieve after being uniformly mixed to ensure the uniformity of the particle size of the mixed powder. Take a small amount of mixed powder, and use a stainless steel mold to cold press at a pressure of 4.0-7.0t / cm 2 Within the range, it is pressed into a green body with a diameter of 3mm and a height of 1.2-2mm.

[0034] (3) the green compact that step (2) is pressed is put into Al 2 o 3 In the crucible, they are placed together in a cavity surrounded by zirconia balls with a diameter of 3 mm as the auxiliary heat material, and are heated in argon-hydrogen (8% H 2 ) under a protectiv...

Embodiment 3

[0039] (1) Take 10g of micron-sized W powder (2.3μm) and 10g of micron-sized Ir powder (5μm), put them into crucibles respectively, and anneal at 1000°C for 1h in a tube furnace fed with hydrogen to ensure the original powder purify.

[0040] (2) According to the mass ratio of 25% Ir and 75% W, the above-mentioned powders were weighed and mechanically mixed and ground, and passed through a 200-mesh sieve after being uniformly mixed to ensure the uniformity of the particle size of the mixed powder. Take a small amount of mixed powder, and use a stainless steel mold to cold press at a pressure of 4.0-7.0t / cm 2 Within the range, it is pressed into a green body with a diameter of 3mm and a height of 1.2-2mm.

[0041] (3) the green compact that step (2) is pressed is put into Al 2 o 3 In the crucible, they are placed together in a cavity surrounded by zirconia balls with a diameter of 3 mm as the auxiliary heat material, and are heated in argon-hydrogen (8% H 2 ) under a protec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com