Packaging structure of igbt chip subunit and manufacturing method thereof

A technology of packaging structure and manufacturing method, applied in semiconductor/solid-state device manufacturing, electrical components, semiconductor/solid-state device components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with accompanying drawing.

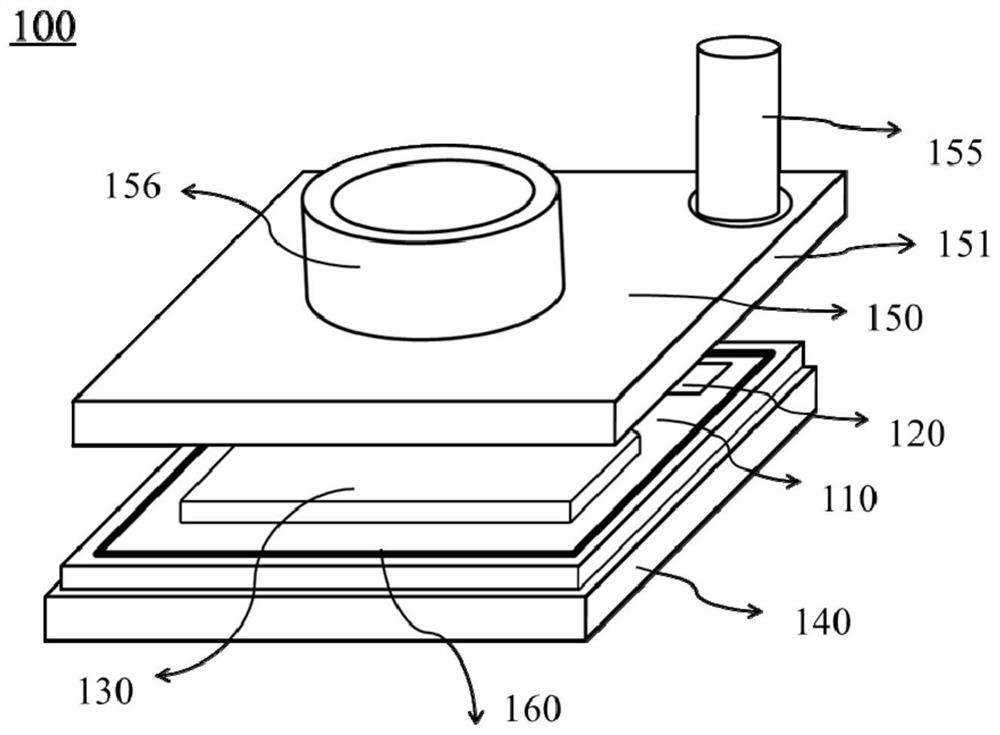

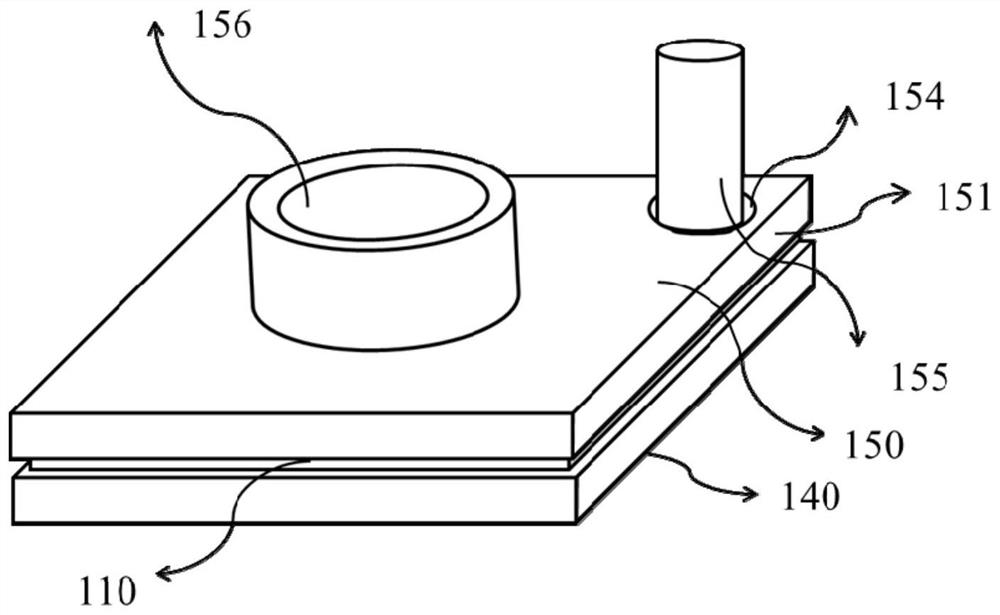

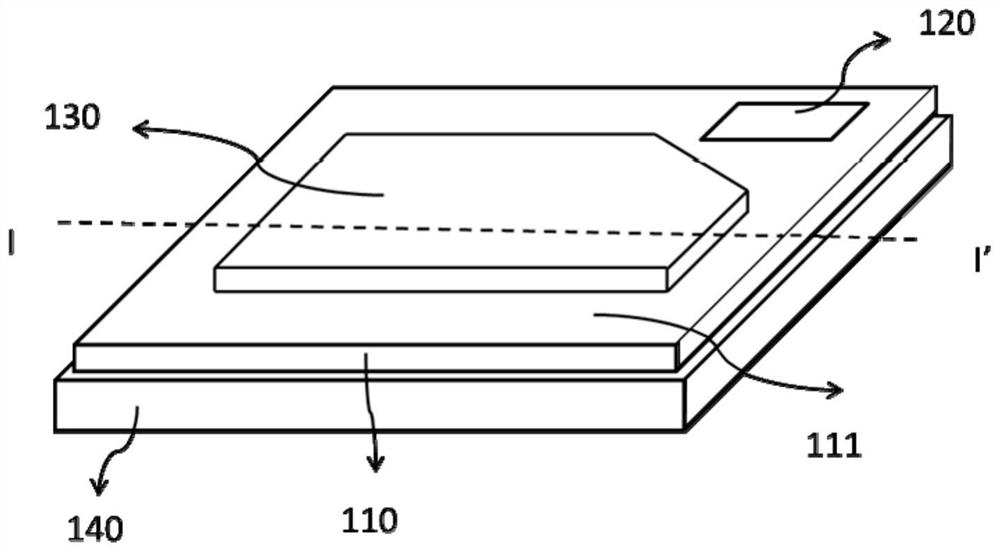

[0036] figure 1 and figure 2 It is a schematic structural diagram of the IGBT chip subunit packaging structure 100 provided in this application. like figure 1 and figure 2 As shown, the packaging structure 100 includes an IGBT chip 110, a gate 120 disposed on the IGBT chip, an upper molybdenum sheet 130 and a lower molybdenum sheet 130 electrically connected to the upper surface emitter 111 and the lower surface collector 112 of the IGBT chip 110 respectively. The chip 140 and the encapsulator 150 are coated with silicon rubber 160 on the emitter electrode 111 on the upper surface and along the terminal area 113 of the IGBT chip 110 .

[0037] Through the packaging structure of the IGBT chip subunit provided in this application, the terminal structure of the IGBT chip can be passivated and protected, preventing electrical breakdown caused by contamination of the chip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com