A new type of screen and its manufacturing method

A production method and screen technology, which are applied in the field of solar cells, can solve the problems of low conversion efficiency of solar cells, increased paste shading area, and reduced number of photons, etc., to achieve reduced silver paste consumption, convenient operation, and reduced paste density. The effect of material width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

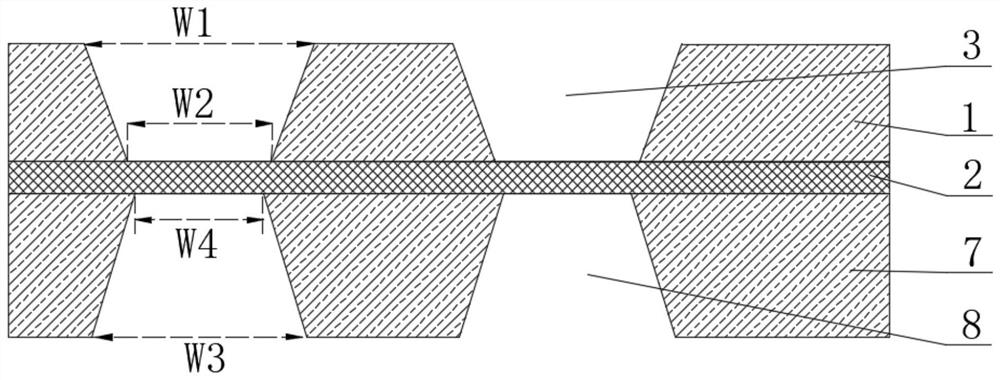

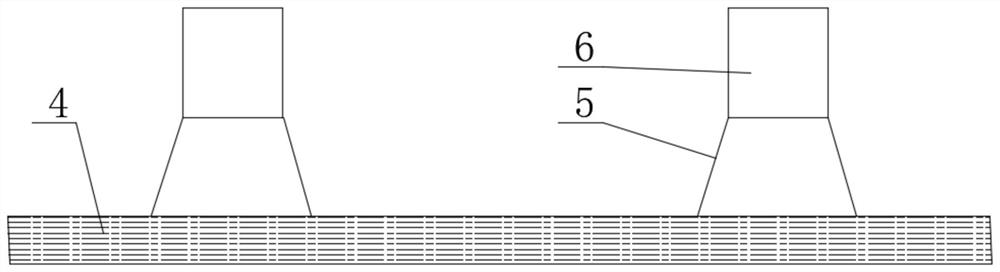

[0031] Such as figure 1 with figure 2 , Figure 4 As shown, the novel screen plate of the present embodiment comprises mesh cloth 2, and the two sides of mesh cloth 2 are respectively provided with upper membrane layer 1 and lower membrane layer 7, and upper membrane layer 1 is provided with at least one upper groove 3, lower The film layer 7 is provided with at least one lower groove 8 , the positions of the upper groove 3 and the lower groove 8 correspond up and down, and the central axes coincide, and the interconnected channels are formed through the mesh cloth 2 .

[0032] The width W1 of the notch of the upper groove 3 is greater than the width W2 of the groove bottom of the upper groove 3, and 5μm≤W2≤40μm, 10μm≤W1≤50μm, and the groove bottom of the upper groove 3 is located close to the mesh cloth 2- side.

[0033] The width W3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com