Alpha-tricalcium phosphate biological ceramic material and preparation method thereof

A bioceramic material, tricalcium phosphate technology, applied in the intersection of material science and biomedicine, can solve the problems of long reaction time and low product yield, and achieve low equipment requirements, good biocompatibility, and simple operation methods. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] 1) Accurately weigh the analytically pure Ca(NO 3 ) 2 4H 2 O 23.615g and (NH 4 ) 2 HPO 4 8.204g, were dissolved in 100ml of distilled water to make a solution.

[0058] 2) At room temperature (25°C), accurately measure 20ml of analytically pure ammonia water with a graduated cylinder, add to (NH 4 ) 2 HPO 4 In the solution, make the pH around 10, under the condition of magnetic stirring, Ca(NO 3 ) 2 Quickly added to the solution (NH 4 ) 2 HPO 4 In the solution, seal the container and keep stirring, and the reaction is completed after 10 minutes.

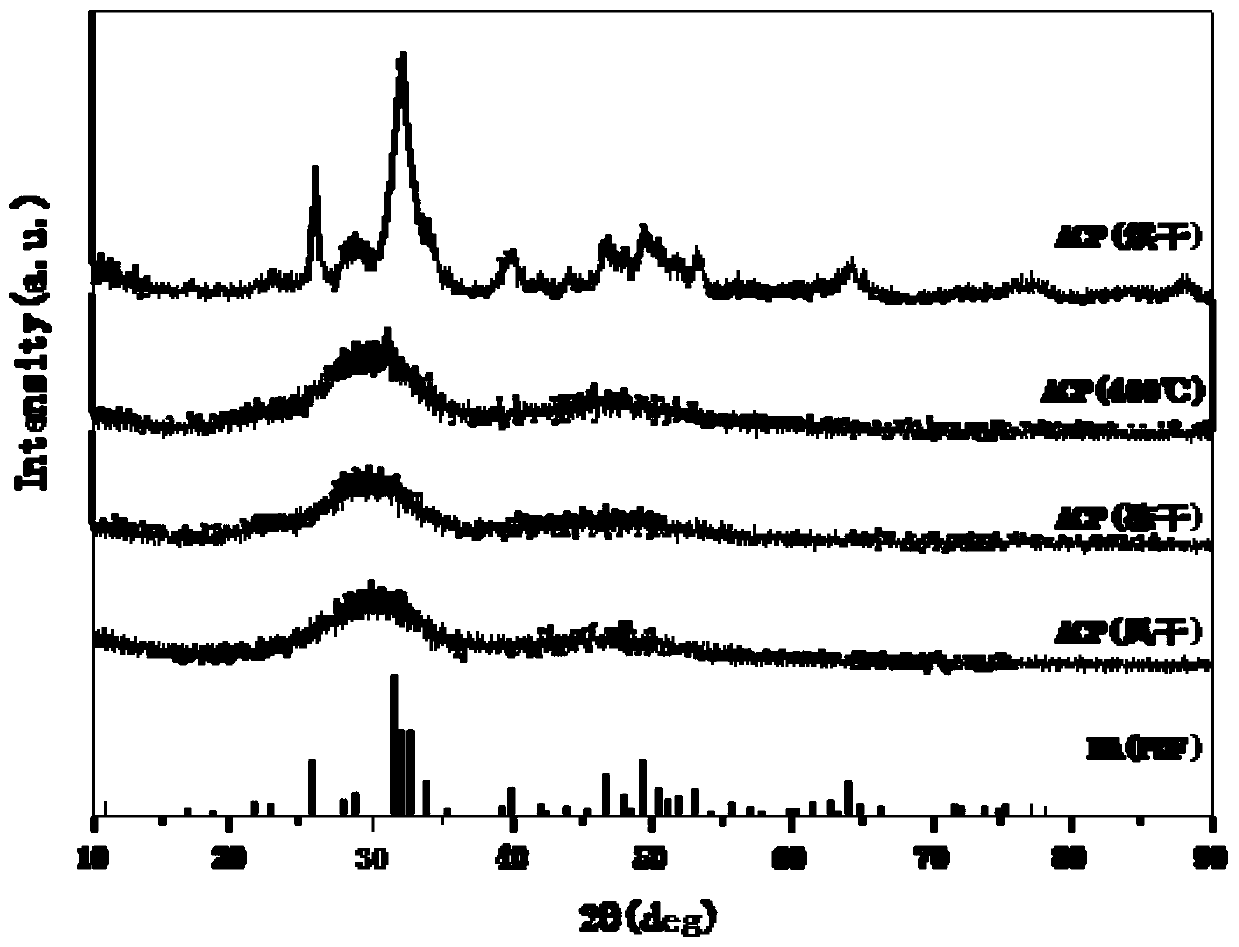

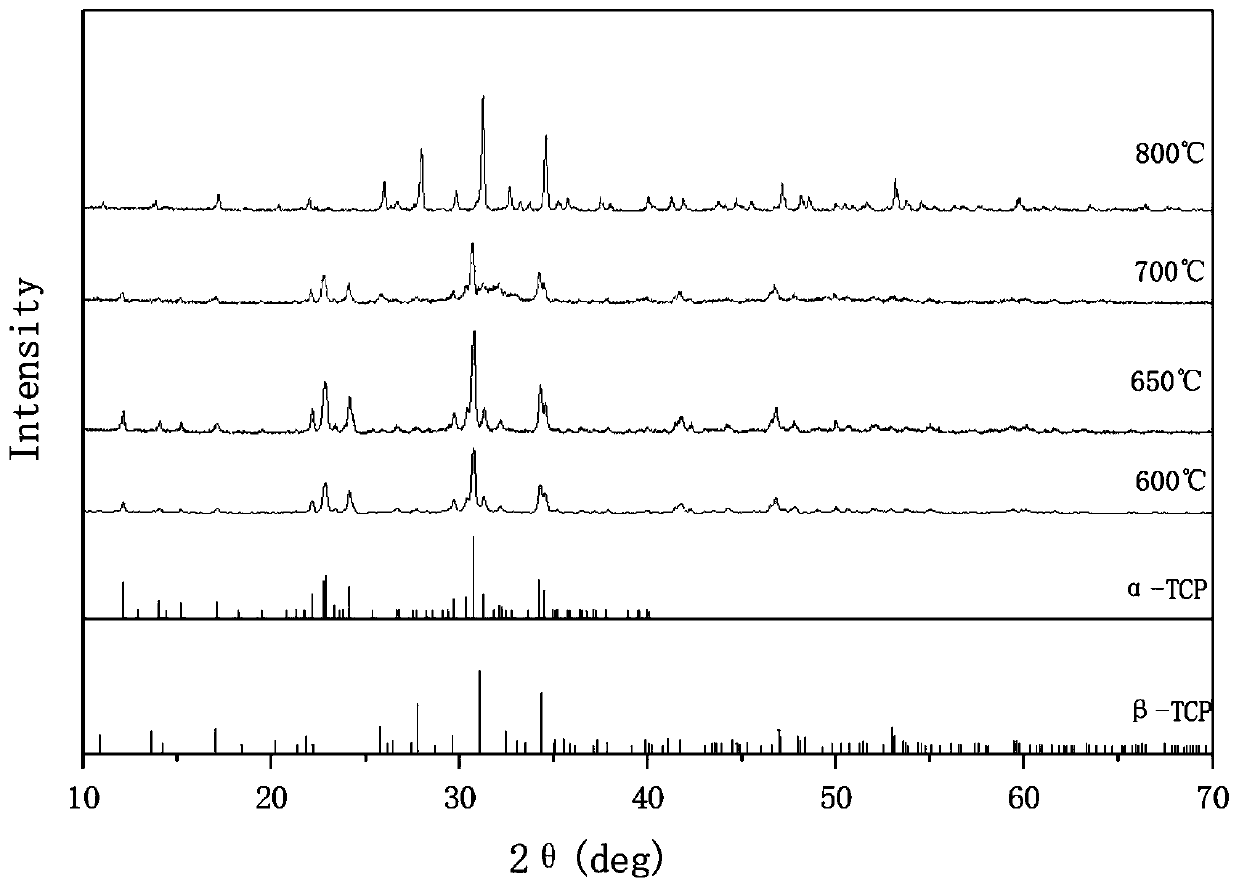

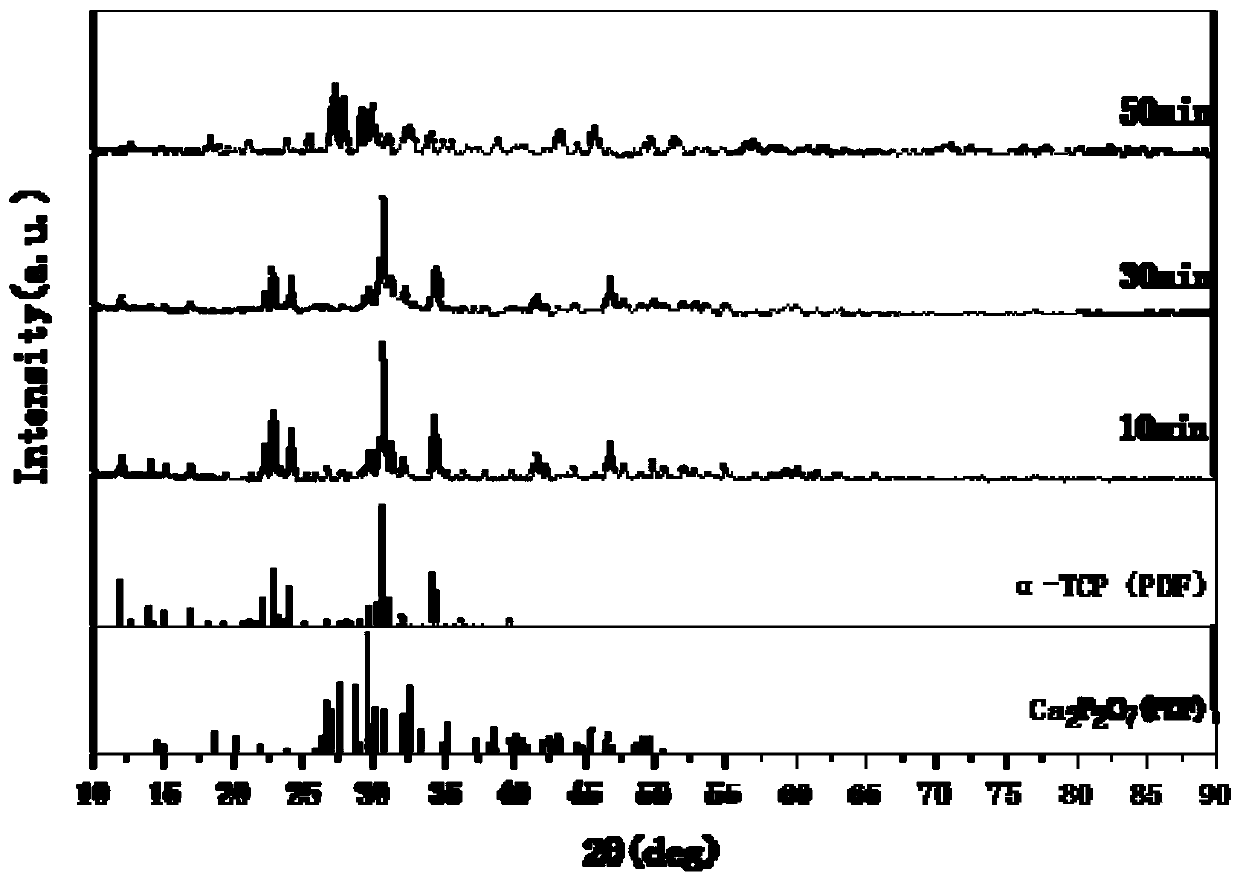

[0059] 3) Suction filter the above solution, wash 3 times with absolute ethanol after the suction filtration, and then air-dry for 4-8 hours (room temperature 25°C); then grind the dried particles in an agate mortar and then calcinate, The calcination treatment conditions are as follows: the heating rate is 10°C / min, the calcination time is 3h, the calcination temperature is 600°C, and the furnace is cooled to ob...

Embodiment 2

[0062] 1) Accurately weigh the analytically pure Ca(NO 3 ) 2 4H 2 O 23.615g and (NH 4 ) 2 HPO 4 8.204g, were dissolved in 100ml of distilled water to make a solution.

[0063] 2) At room temperature (25°C), accurately measure 20ml of analytically pure ammonia water with a graduated cylinder, add to (NH 4 ) 2 HPO 4 In the solution, make the pH around 10, under the condition of magnetic stirring, Ca(NO 3 ) 2 Quickly added to the solution (NH 4 ) 2 HPO 4 In the solution, seal the container and keep stirring, and the reaction is completed after 10 minutes.

[0064] 3) Suction filter the above solution, wash 3 times with absolute ethanol after the suction filtration, and then air-dry for 4-8 hours; then grind the dried particles in an agate mortar and then calcinate, the calcination treatment conditions are: The heating rate is 10°C / min, the calcination time is 3h, the calcination temperature is 650°C, and the α-tricalcium phosphate powder is obtained by cooling with ...

Embodiment 3

[0067] 1) Accurately weigh the analytically pure Ca(NO 3 ) 2 4H 2 O 23.615g and (NH 4 ) 2 HPO 4 8.204g, were dissolved in 100ml of distilled water to make a solution.

[0068] 2) At room temperature (25°C), accurately measure 20ml of analytically pure ammonia water with a graduated cylinder, add to (NH 4 ) 2 HPO 4 In the solution, make the pH around 10, under the condition of magnetic stirring, Ca(NO 3 ) 2 Quickly added to the solution (NH 4 ) 2 HPO 4 In the solution, seal the container and keep stirring, and the reaction is completed after 10 minutes.

[0069] 3) Suction filter the above solution, wash 3 times with absolute ethanol after the suction filtration, and then air-dry for 4-8 hours; then grind the dried particles in an agate mortar and then calcinate, the calcination treatment conditions are: The heating rate is 10°C / min, the calcination time is 3h, the calcination temperature is 700°C, and the α-tricalcium phosphate powder is obtained by cooling with ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap