External curing agent for concrete

A curing agent and concrete technology, applied in the field of concrete external curing agent, can solve the problems of reducing the wear resistance and strength of concrete surface, high maintenance cost, high price, etc., and achieve the effect of increasing strength and saving maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

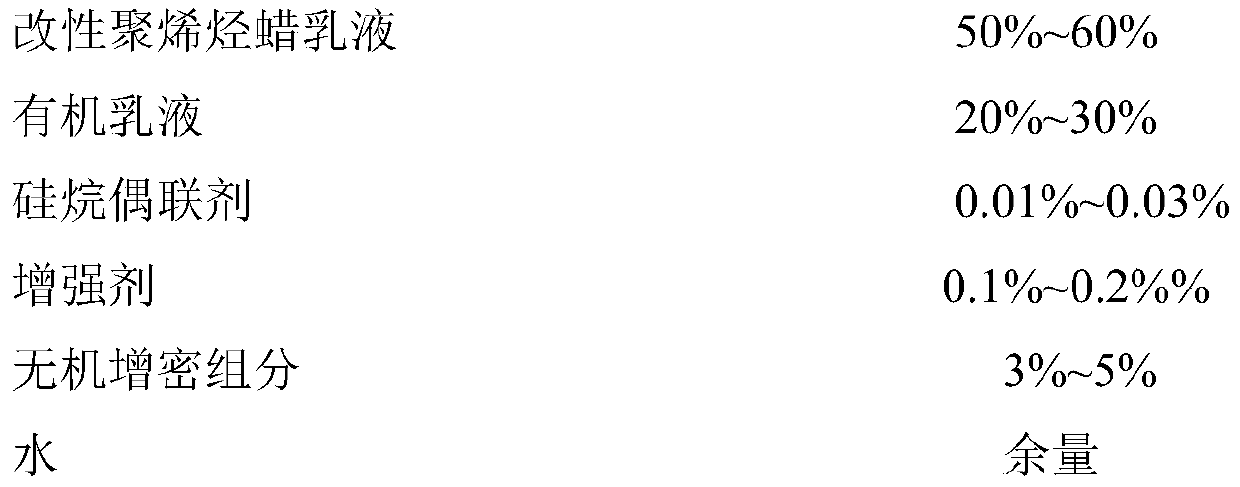

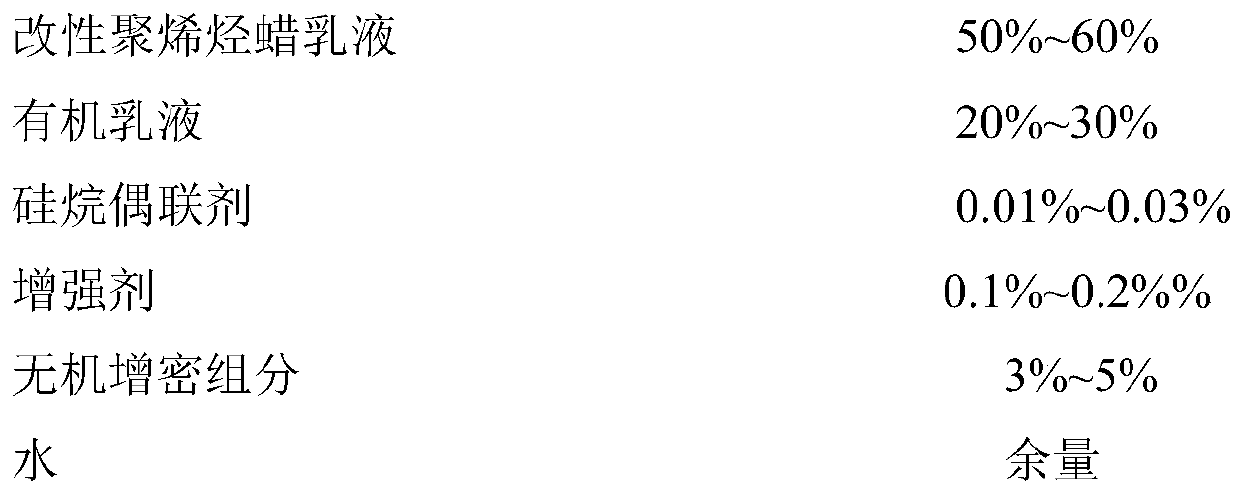

Method used

Image

Examples

Embodiment 1

[0013] A kind of preparation method of external curing agent for concrete is:

[0014] Step 1: take each raw material by weight percentage;

[0015] Modified polyolefin wax emulsion 60%, pure acrylic emulsion 30%, vinyl triethoxysilane coupling agent 0.02%, triethanolamine 0.02%, sodium silicate 3%, tap water 6.96%

[0016] Step 2: Put the weighed raw materials in a forced mixer and mix them evenly to obtain the concrete external curing agent.

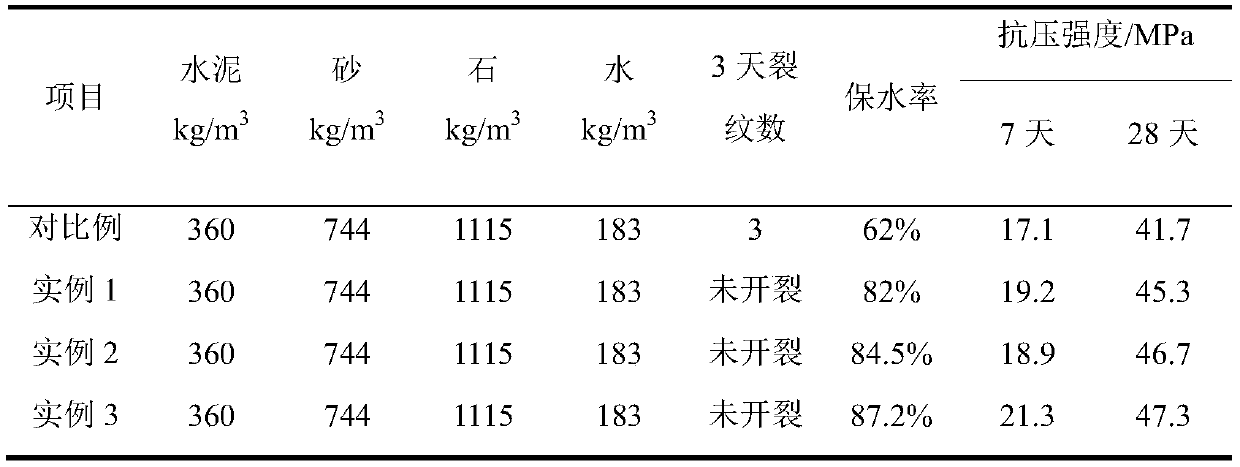

[0017] Spray on the surface of concrete components and concrete compressive strength test pieces according to the amount of 1.0Kg / m2, place the concrete components in an environment with a temperature of 40°C and a wind speed of 5m / s, and observe the cracking situation after 3 days; concrete compressive strength test pieces Place it in an environment with a temperature of 20°C±5°C and a humidity of 50%, and wait to test the compressive strength for 7d and 28d. (Test results are listed in Table 1)

Embodiment 2

[0019] A kind of preparation method of external curing agent for concrete is:

[0020] Step 1: Weigh each raw material by weight percentage; modified polyolefin wax emulsion 60%, styrene-acrylic emulsion 30%, vinyltrimethoxysilane coupling agent 0.02%, triisopropanol 0.02%, sodium silicate 3 %, tap water 6.96%

[0021] Step 2: Put the weighed raw materials in a forced mixer and mix them evenly to obtain the concrete external curing agent.

[0022] Spray on the surface of concrete components and concrete compressive strength test pieces according to the amount of 1.0Kg / m2, place the concrete components in an environment with a temperature of 40°C and a wind speed of 5m / s, and observe the cracking situation after 3 days; concrete compressive strength test pieces Place it in an environment with a temperature of 20°C±5°C and a humidity of 50%, and wait to test the compressive strength for 7d and 28d. (Test results are listed in Table 1)

Embodiment 3

[0024] A kind of preparation method of external curing agent for concrete is:

[0025] Step 1: Weigh each raw material by weight percentage; modified polyolefin wax emulsion 60%, styrene-acrylic emulsion 30%, vinyltrimethoxysilane coupling agent 0.02%, triethanolamine 0.03%, sodium silicate 5%, tap water 4.95%

[0026] Step 2: Put the weighed raw materials in a forced mixer and mix them evenly to obtain the concrete external curing agent.

[0027] Spray on the surface of concrete components and concrete compressive strength test pieces according to the amount of 1.0Kg / m2, place the concrete components in an environment with a temperature of 40°C and a wind speed of 5m / s, and observe the cracking situation after 3 days; concrete compressive strength test pieces Place it in an environment with a temperature of 20°C±5°C and a humidity of 50%, and wait to test the compressive strength for 7d and 28d. (Test results are listed in Table 1)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com