Resin composition, prepreg and laminated board

A technology of resin composition and prepreg, which is applied in the field of prepreg, laminate and resin composition, to achieve the effects of improving production efficiency, saving process cost, and good mechanical and thermal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Step 1: Add 3.5 parts of dicyandiamide, 0.9 parts of dimethylimidazole, and 1.8 parts of N-acyl imidazole into 60 parts of N,N-dimethylformamide and acetone organic solvent, and add 100 parts of bisphenol after the dissolution is complete A epoxy resin is prepared as an epoxy resin composition.

[0027] Step 2: Evenly coat the epoxy resin composition on the electronic grade glass fiber cloth and bake at 120--180°C for 2-5 minutes, then cool to room temperature to make a prepreg;

[0028] Step 3: Stack the prepreg 1 to multi-layer prepreg, attach the release film on both sides, stack the stainless steel plate up and down, send it into the stacked hot press machine, 140-160℃ / 0.5-5MPa high temperature and high pressure molding for 15-30min , made of thermosetting laminates ①.

[0029] Step 4: Store the prepreg at room temperature for 1 month, and perform hot-press molding according to the process of step 3 to make a thermosetting laminate②.

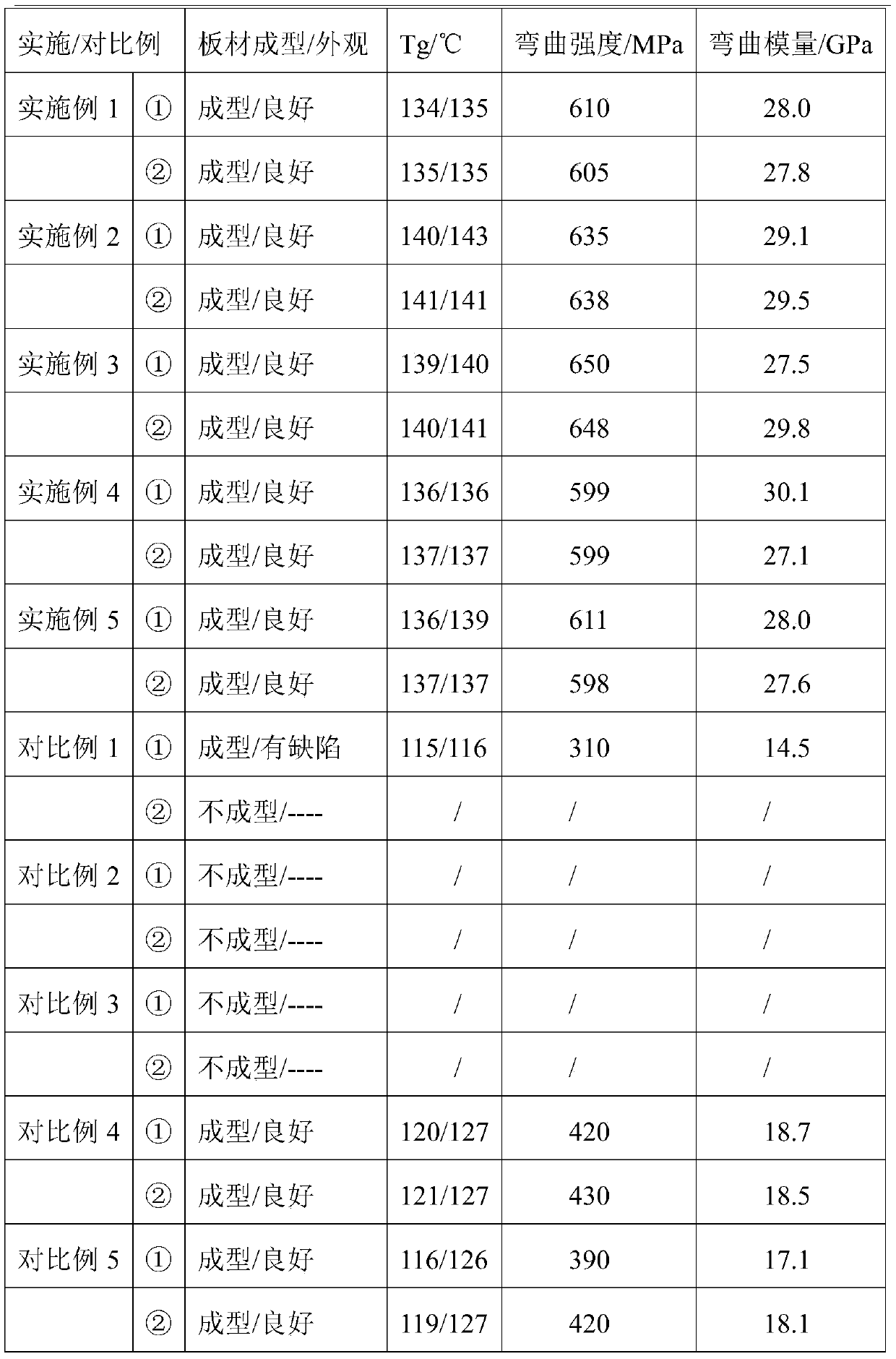

[0030] Observe the molding o...

Embodiment 2

[0032] Step 1: Add 10.3 parts of diaminodiphenyl sulfone, 1.9 parts of 2-ethyl-4 methylimidazole, 1.3 parts of tetramethylethylenediamine to 60 parts of N,N-dimethylformamide and acetone organic solvent After dissolving completely, add 100 parts of bisphenol A epoxy resin to prepare epoxy resin composition.

[0033] Preparation and testing were carried out according to the process steps of Example 1.

Embodiment 3

[0035] Step 1: Add 39.5 parts of linear phenol formaldehyde resin, 1.4 parts of 2-undecylimidazole (C11Z) imidazole, 2.3 parts of 1,2-dimethylimidazole to 80 parts of N,N-dimethylformamide and propylene glycol formaldehyde In the ether organic solvent, add 100 parts of bisphenol A epoxy resin and mix evenly after dissolving completely, and add 20 parts of silicon dioxide, 10 parts of titanium dioxide, 5 parts of talc powder, 0.8 parts of silane coupling agent, and 0.5 parts of fatty acid dispersant part, fully stirred to prepare an epoxy resin composition.

[0036] Preparation and testing were carried out according to the step process of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com