Special substrate sealing agent for dyed veneers and preparation method thereof

A technology of sealant and substrate, which is applied in the field of special substrate sealant for dyed veneer and its preparation, can solve the problems of inconsistent oxidation on the surface of dyed veneer, easy leakage of wood oil, and poor sealing performance, so as to prevent the leakage of veneer pipes, Strong anti-light aging ability, improve sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

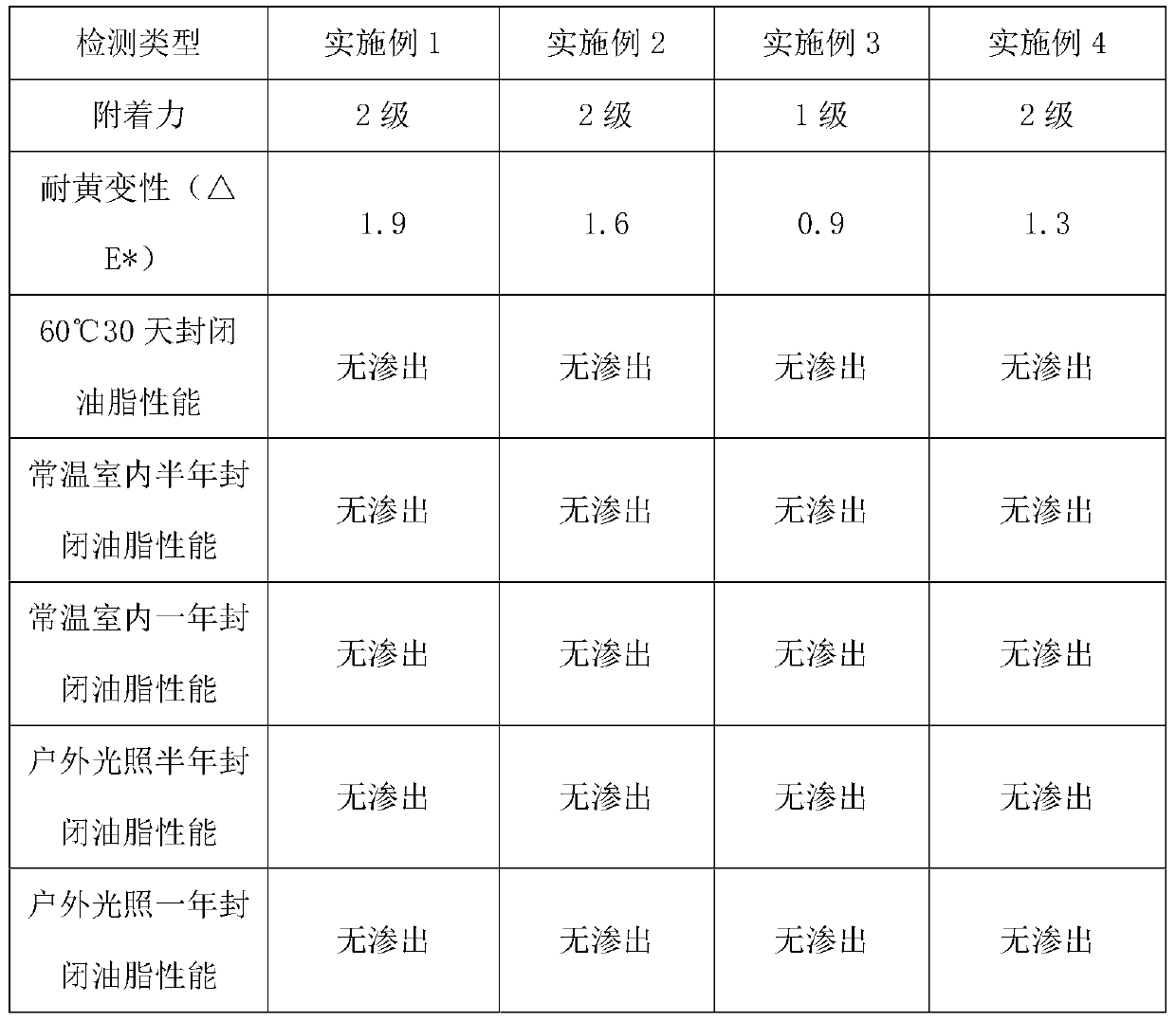

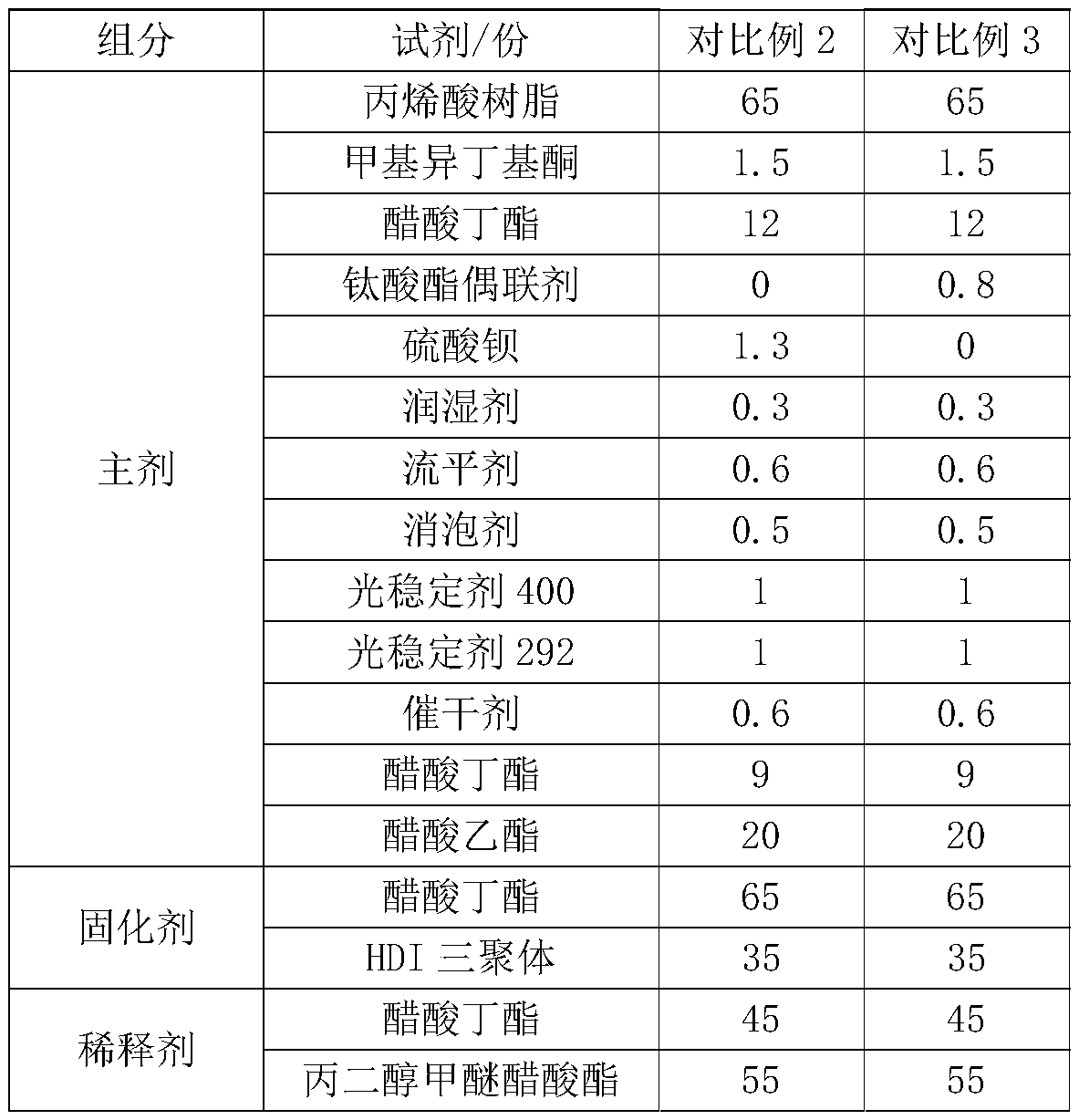

Examples

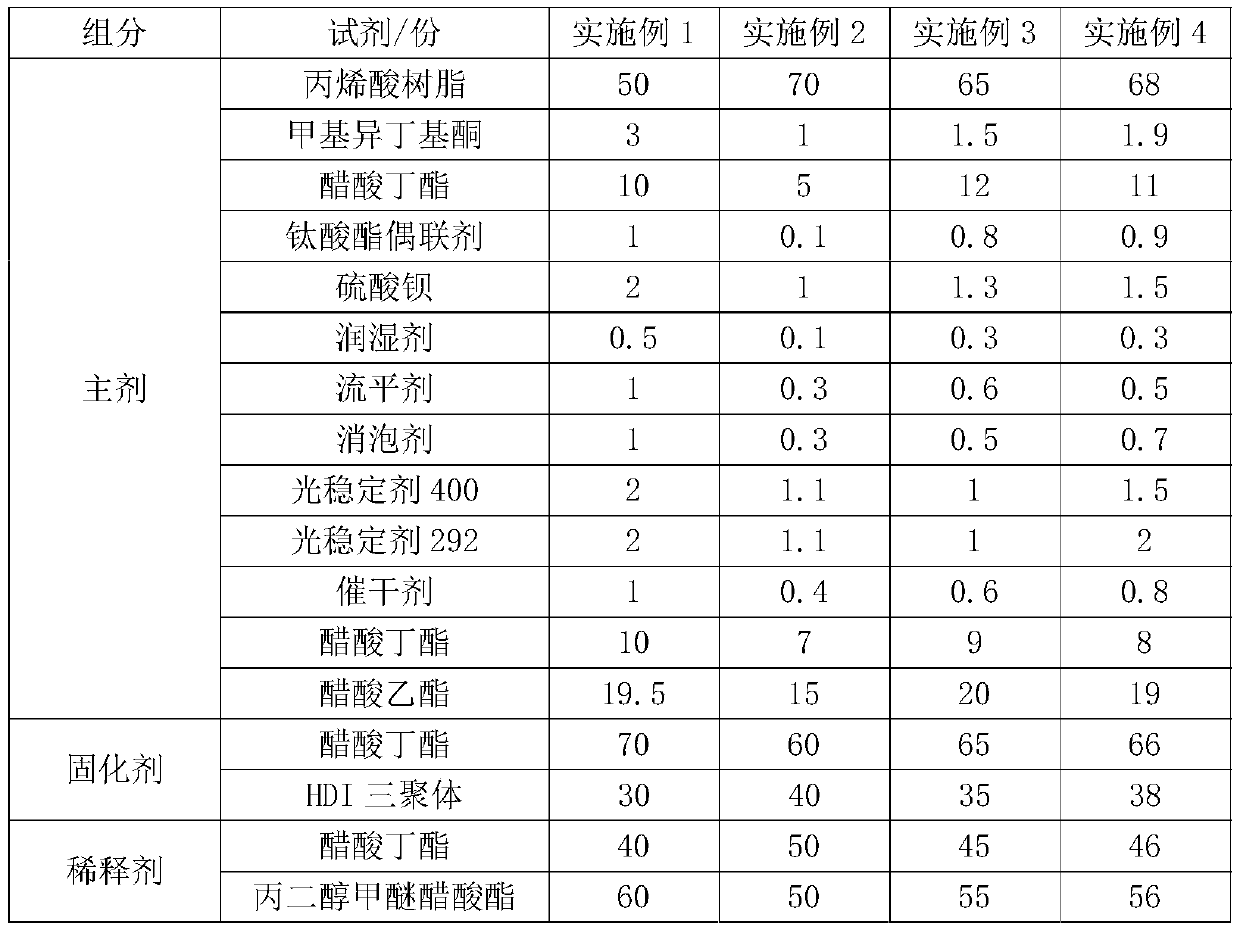

Embodiment 1-4

[0024] A preparation method of a special substrate sealant for dyeing veneer, which is prepared by the following method:

[0025] (1) Preparation of main agent: Choose a clean dispersing tank that meets the standard, and sequentially put in acrylic resin, methyl isobutyl ketone, butyl acetate, titanate coupling agent, barium sulfate, wetting agent, leveling agent, and disinfectant. After foaming agent, light stabilizer drier, butyl acetate and ethyl acetate materials, start the dispersing machine and disperse at a low speed of 800-900 rpm, viscosity: 1500±200CPS / 30℃;

[0026] (2) Preparation of curing agent: Choose a clean dispersing tank that meets the standard, put in butyl acetate and HDI trimer materials in turn, start the disperser, disperse at 800-900 revolutions / min for 30 minutes, and cool to 30 after holding at 65°C. ℃ Discharge and seal; after qualified, use 200 strainer to filter and pack into barrels for later use;

[0027] (3) Preparation of thinner: Choose a clean disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com