Preparation method of organic crystalline material, organic crystalline material, and light-emitting element

A technology of organic crystals and light-emitting elements, which is applied in the preparation of organic crystal materials, organic crystal materials and light-emitting elements, can solve the problems of slow crystal growth, weak interaction, and inability to realize preparation, and achieve the effect of high doping concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] In the preparation method of the organic crystal material provided by the embodiment of the present invention, in an inert environment, heat and anneal the two stacked metal complex amorphous doped films, and then cool to room temperature, wherein the metal complex amorphous doped film The host material is a complex of the first metal and the first ligand, and the guest material is the complex of the second metal and the second ligand; and, the difference between the metal atomic numbers of the first metal and the second metal is ≥ 10, the second A ligand is identical or has a spatially similar structure to a second ligand.

[0037]Although the method of high temperature crystallization can ensure fast and efficient preparation of organic crystal materials, the interaction between organic crystals is still weak at this time. In order to make molecules crystallize better and maintain long-term stability, In the preparation method of the organic crystal material provided ...

Embodiment 1

[0049] Raw material: guest material Ir(ppy) 3 and host material Alq 3

[0050] Preparation method: please refer to figure 1 ,

[0051] 1) In an inert environment, the guest material Ir(ppy) will be 3 and host material Alq 3 Two pieces of metal complex amorphous doped films prepared by co-evaporation are stacked face to face, and then placed on a closed hot stage;

[0052] 2) Heating the stacked metal complex amorphous doped film to 300°C and annealing for 25 minutes;

[0053] 3) Stop heating and cool to room temperature in a nitrogen environment to obtain defect-induced organic crystal materials.

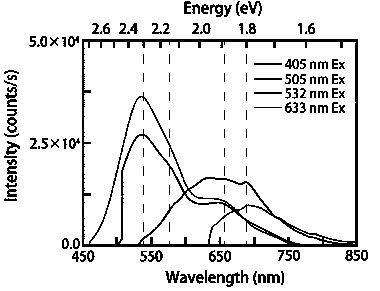

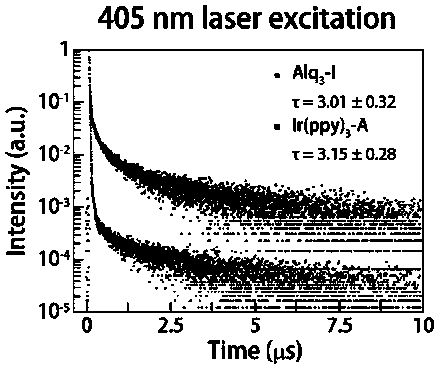

[0054] Product performance test: due to Ir(ppy) 3 Guest material and host material Alq 3 The ligand structure has a similar structure, the ligand of the guest material is phenylpyridine, and the ligand of the host material is hydroxyquinoline; and the atomic radius of the metal complex of the host material and the guest material has a large gap, and the guest material is He...

Embodiment 2

[0056] Raw material: guest material Alq 3 and host material Ir(ppy) 3

[0057] Preparation:

[0058] 1) In an inert environment, the guest material Alq 3 and host material Ir(ppy) 3 Two pieces of metal complex amorphous doped films prepared by co-evaporation are stacked face to face, and then placed on a closed hot stage;

[0059] 2) Heating the stacked metal complex amorphous doped film to 300°C and annealing for 25 minutes;

[0060] 3) Stop heating and cool to room temperature in a nitrogen environment to obtain defect-induced organic crystal materials.

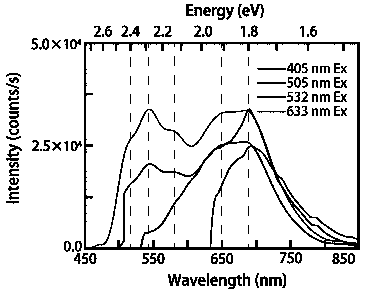

[0061] Product performance test: due to Alq 3 Guest material and host material Ir(ppy) 3 The ligand structure has a similar structure, the ligand of the guest material is hydroxyquinoline, and the ligand of the host material is phenylpyridine; and the atomic radius of the metal complex of the host material and the guest material has a large gap, and the guest material is Light metal Al, the main material is heavy me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com