Fe-Ni-Co composite Fenton-like catalyst and preparation method thereof

A fe-ni-co, composite technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of poor activity and long time consumption, and achieve rich adsorption capacity and process Simple, non-polluting process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

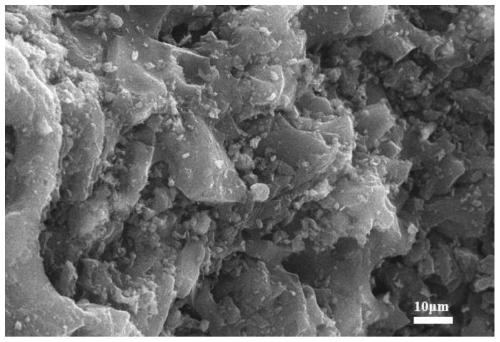

[0051] Pretreatment: Wash the activated carbon once with deionized water, transfer it to a high-temperature reactor and react at a high temperature of 100°C for 6 hours; after the reaction, wash it repeatedly with deionized water until it is neutral, and dry it at 50°C for 8 hours to complete the pretreatment of the carbon-based carrier. deal with.

[0052] Dissolve 4.04g of ferric nitrate, 1.16g of terephthalic acid in 50mL of DMF solution, add terephthalic acid and benzimidazole and stir to dissolve in DMF solution, stir well, add pretreated activated carbon and stir for 1-4h . Transfer to a high-temperature reactor, perform high-temperature hydrothermal reaction at 100-180°C for 9-20 hours, filter out the material after synthesis, pour off the supernatant of the reactor, and dry in an oven at 60-90°C for 4-8 hours.

[0053] Heating to 200-500°C in an air atmosphere at a heating rate of 10°C / min for calcination in a muffle furnace for 1-3h, then cooling to room temperature;...

Embodiment 2

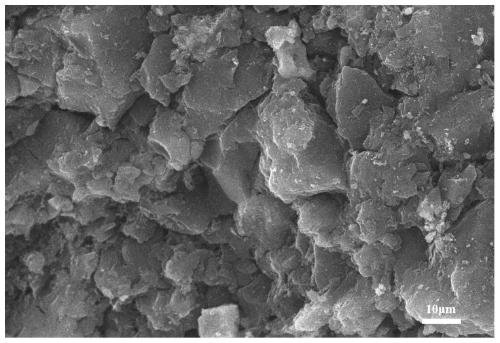

[0055] Pretreatment: Wash the coconut shell activated carbon with deionized water once, transfer it to a high-temperature reactor and react at a high temperature of 150°C for 2 hours; after the reaction, wash it repeatedly with deionized water until it is neutral, and dry it at 80°C for 5 hours to complete the carbon-based carrier preprocessing.

[0056] Dissolve 2.828g of iron nitrate, 0.872g of nickel nitrate (Fe:Ni=7:3), 1.16g of terephthalic acid in 50mL of DMF, add terephthalic acid and benzimidazole and stir to dissolve in the DMF solution, stir After uniformity, add pretreated coconut shell activated carbon and stir for 1 hour. Transfer to a high-temperature reactor, and perform a high-temperature hydrothermal reaction at 100°C for 20 hours. After the synthesis, the material was filtered out, and the supernatant of the reactor was poured out, and dried in an oven at 60°C for 8 hours.

[0057] Heating to 200°C in an air atmosphere at a heating rate of 10°C / min and calci...

Embodiment 3

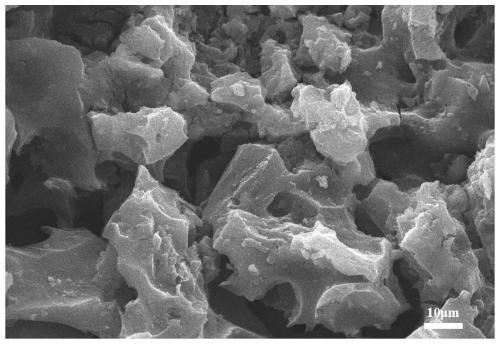

[0059] Pretreatment: Wash the carbon felt once with deionized water, transfer it to a high-temperature reactor and react at a high temperature of 120°C for 3 hours; after the reaction, wash it repeatedly with deionized water until it is neutral, and dry it at 60°C for 7 hours to complete the carbon-based carrier. preprocessing.

[0060] Dissolve 2.424g iron nitrate, 1.163g nickel nitrate (Fe: Ni=6; 4), 1.16g terephthalic acid in 50mL of DMF, add terephthalic acid and benzimidazole and stir to dissolve in the DMF solution, stir After uniformity, add the pretreated carbon felt and stir for 1-4 hours. Transfer to a high-temperature reactor, and conduct a high-temperature hydrothermal reaction at 110°C for 18 hours. After the synthesis, the material was filtered out, and the supernatant of the reactor was poured out, and dried in an oven at 65°C for 7 hours.

[0061] Heated to 220°C in an air atmosphere at a heating rate of 10°C / min and calcined in a muffle furnace for 2 hours, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com