Manganese-based bimetallic oxide mesoporous material, and preparation method and application thereof

A technology of bimetallic oxides and mesoporous materials, applied in the direction of silicon compounds, non-metallic elements, chemical instruments and methods, etc., can solve the problems of inseparable recovery of catalysts, narrow adaptable range of reaction pH, etc., and achieve low energy consumption and low cost. The effect of easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

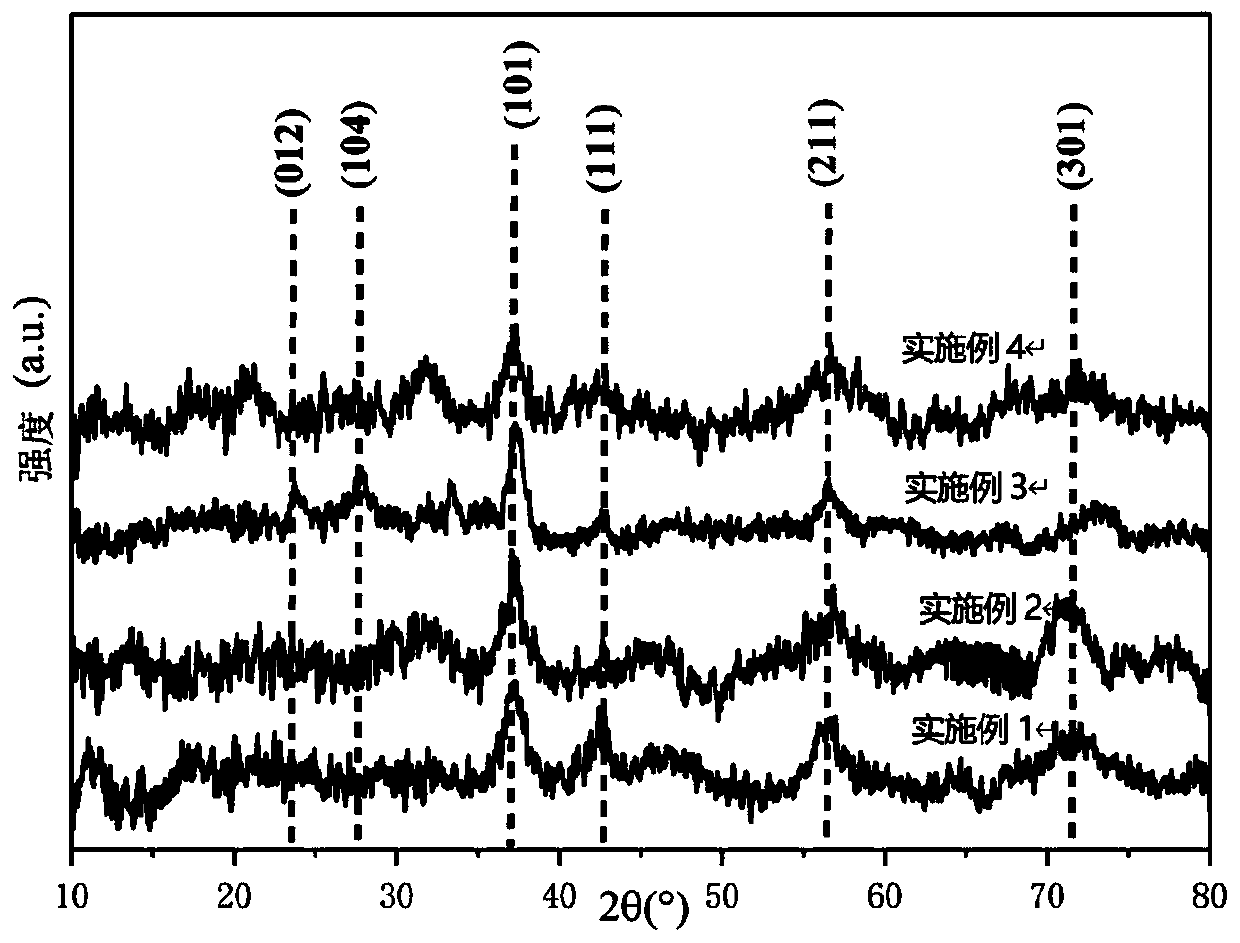

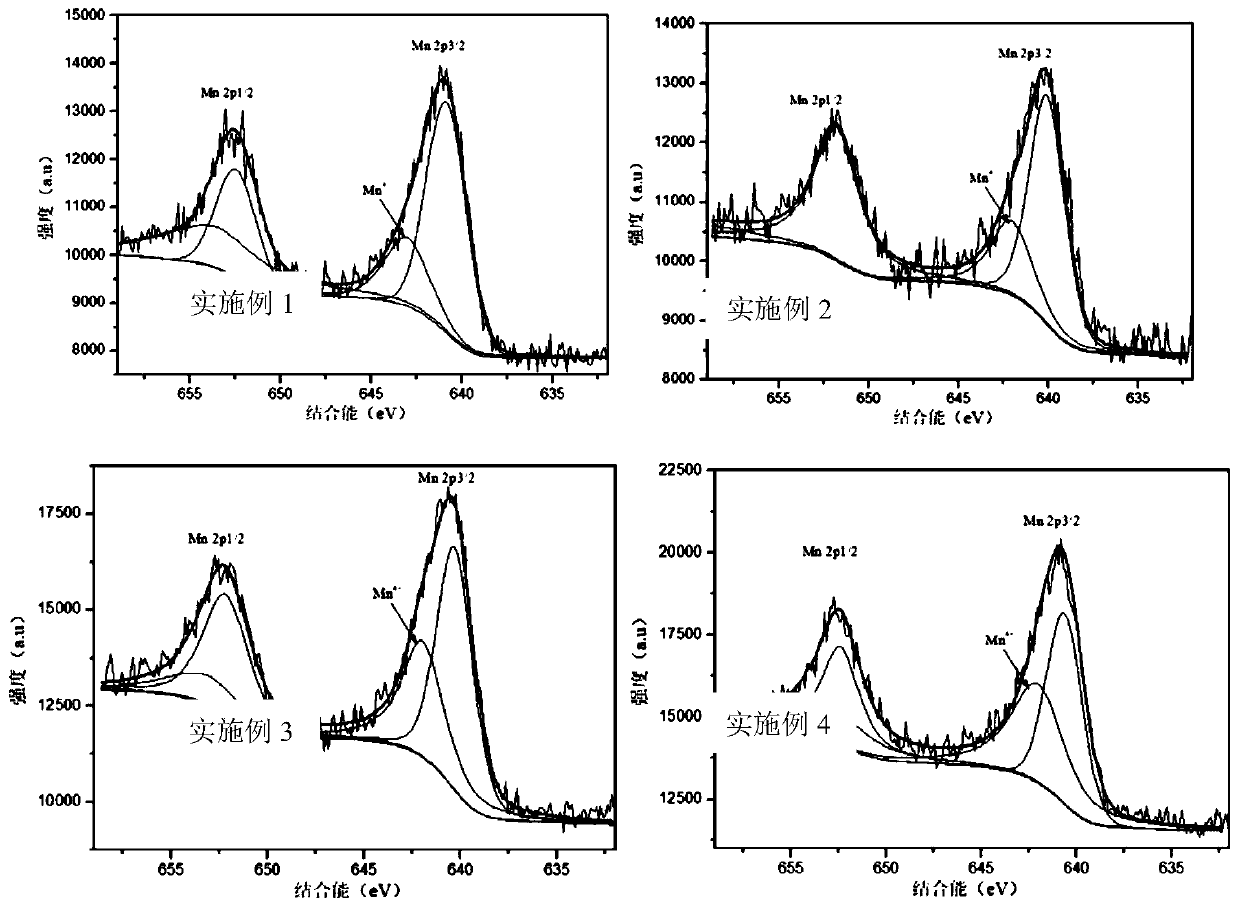

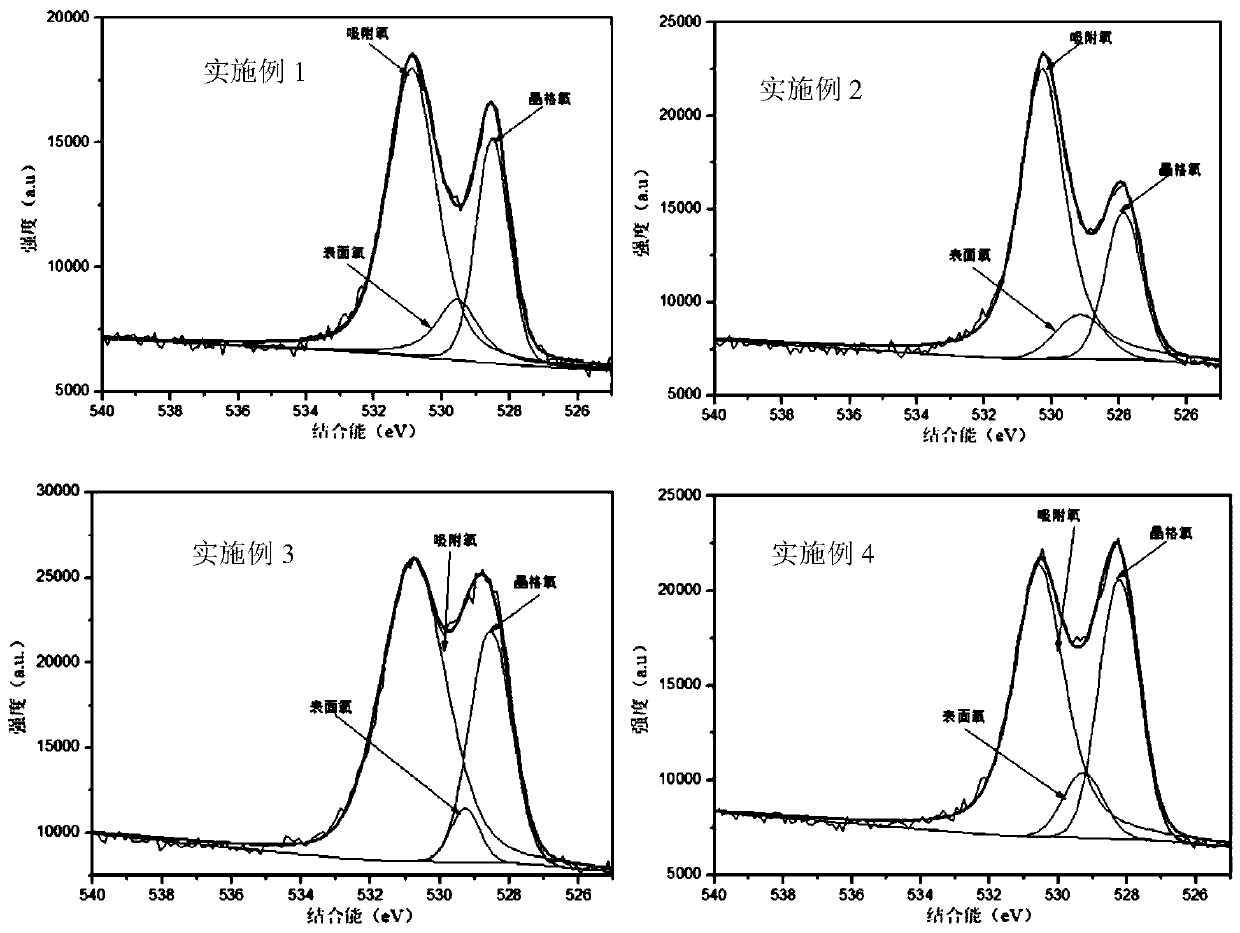

Embodiment 1

[0047] (1) Catalyst preparation

[0048] Add 3.0g SBA-15 silicon template agent into 100mL acetone and disperse under stirring until a stable suspension system is formed. Then, 2 mL of 30% manganese nitrate aqueous solution was added to the suspension system while stirring in a water bath at 30° C., and the stirring and adsorption were continued for one hour. The suspension solution was filtered, washed, and dried at room temperature, then transferred to a muffle furnace for calcination at 500°C for 1 hour to form a composite of manganese oxide and SBA-15. Then, redisperse the compound of manganese oxide and SBA-15 in 100mL of acetone, and add 1mL of 5% ferric nitrate aqueous solution to the suspension system while stirring in a water bath at 0°C. After half an hour of adsorption, continue to add Add 2mL of 30% manganese nitrate aqueous solution, continue to stir and absorb for half an hour. The above suspension solution is filtered, washed and dried, then transferred to a m...

Embodiment 2

[0055] (1) Catalyst preparation

[0056] Add 3.0g SBA-15 silicon template agent into 100mL acetone and disperse under stirring until a stable suspension system is formed. Then, 2 mL of 30% manganese nitrate aqueous solution was added to the suspension system while stirring in a water bath at 30° C., and the stirring and adsorption were continued for one hour. The suspension solution was filtered, washed, and dried at room temperature, then transferred to a muffle furnace for calcination at 500°C for 1 hour to form a composite of manganese oxide and SBA-15. Then, redisperse the compound of manganese oxide and SBA-15 in 100mL of acetone, add 1mL of 10% ferric nitrate aqueous solution to the suspension system while stirring in a water bath at 0°C, after half an hour of adsorption, continue to add to the suspension system Add 2mL of 30% manganese nitrate aqueous solution, continue to stir and absorb for half an hour. The above suspension solution is filtered, washed and dried, t...

Embodiment 3

[0063] (1) Catalyst preparation

[0064] Add 3.0g SBA-15 silicon template agent into 100mL acetone and disperse under stirring until a stable suspension system is formed. Then, 2 mL of 30% manganese nitrate aqueous solution was added to the suspension system while stirring in a water bath at 30° C., and the stirring and adsorption were continued for one hour. The suspension solution was filtered, washed, and dried at room temperature, then transferred to a muffle furnace for calcination at 500°C for 1 hour to form a composite of manganese oxide and SBA-15. Then, redisperse the compound of manganese oxide and SBA-15 in 100mL of acetone, add 1mL of 15% ferric nitrate aqueous solution to the suspension system while stirring in a water bath at 0°C, after half an hour of adsorption, continue to add to the suspension system Add 2mL of 30% manganese nitrate aqueous solution, continue to stir and absorb for half an hour. The above suspension solution is filtered, washed and dried, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com