A method of laser additive manufacturing shear type phase change crack resistance

A laser additive and additive manufacturing technology, which is applied in the direction of additive manufacturing, additive processing, and process efficiency improvement, can solve the problems of residual tensile stress and related cracks in 3D printing alloys

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) SLM printing single-phase FCC high-entropy alloy, single-phase FCC high-entropy alloy components are: Fe 20at.%, Mn20at.%, Co 20at.%, Cr 20at.%, Ni 20at.%.;

[0028] Additive manufacturing of high-entropy alloy powder with the above ingredients, the preparation method is gas atomization method, firstly, the prepared metal block is vacuum smelted, and then an inert gas is used for atomization and powder making, and the inert gas used is argon . The specific parameters for melting are: melting temperature: 1550°C; pressure inside the melting furnace is 0.5MPa; atomization pressure is 7MPa. The atomized metal powder is sieved and classified, and the metal powder with a mesh number of 200-325 is used as the raw material powder for additive manufacturing.

[0029] (2) Before additive manufacturing, the metal powder was dried in a vacuum oven for 12 hours at a drying temperature of 120°C.

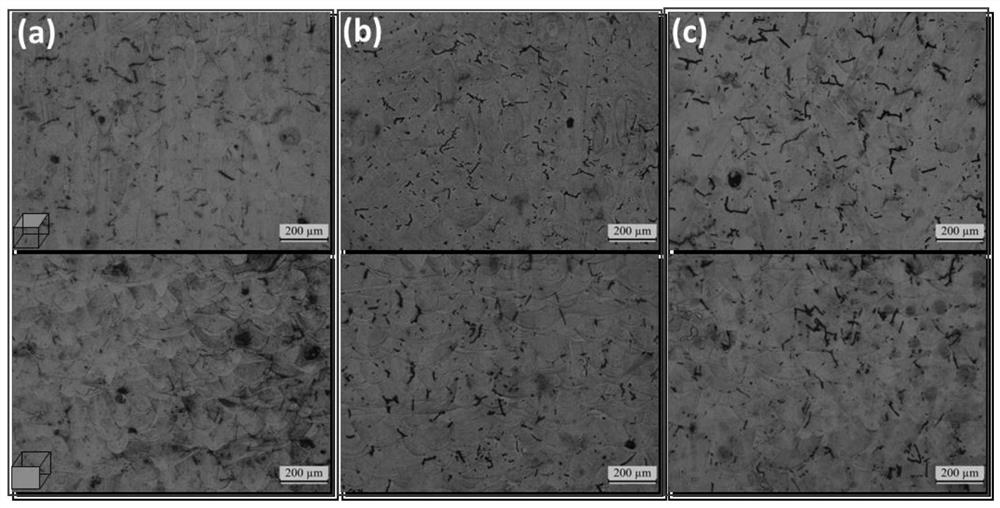

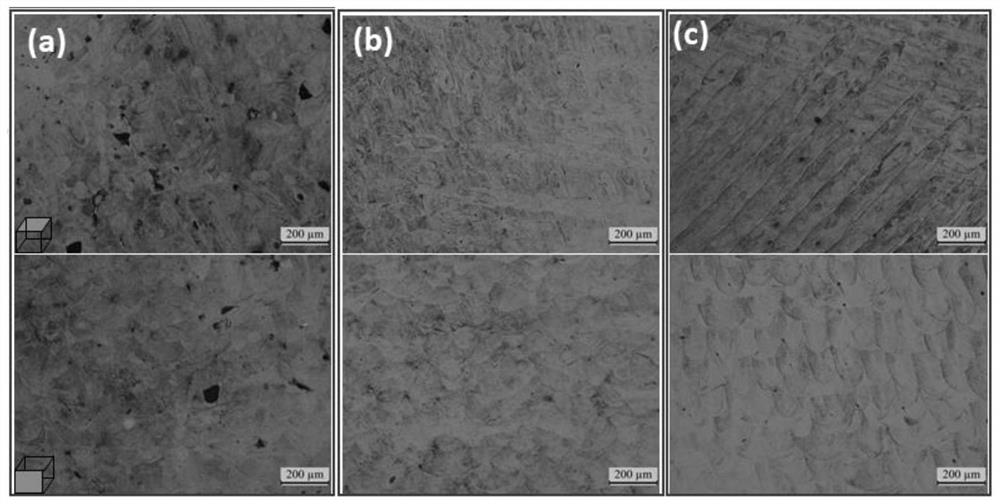

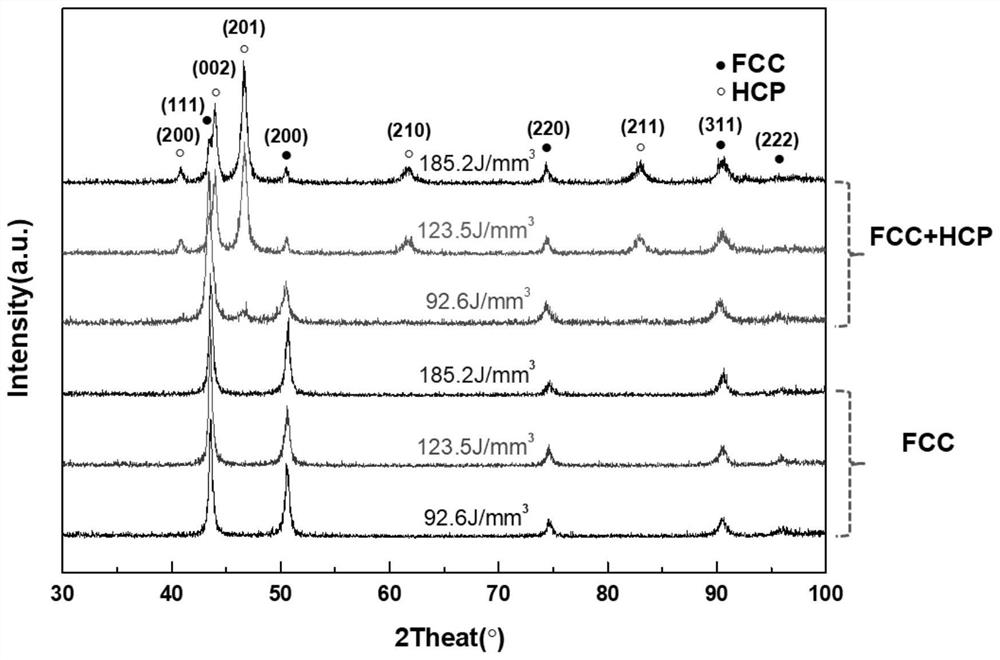

[0030](3) Perform additive manufacturing printing on the above-mentioned dried h...

Embodiment 2

[0034] (1) SLM prints single-phase FCC high-entropy alloys. The components of single-phase FCC high-entropy alloys are: Fe 25at.%, Co25at.%, Cr 25at.%, Ni 25at.%.;

[0035] Additive manufacturing of high-entropy alloy powder with the above ingredients, the preparation method is gas atomization method, firstly, the prepared metal block is vacuum smelted, and then an inert gas is used for atomization and powder making, and the inert gas used is argon . The specific parameters for melting are: melting temperature: 1550°C; pressure inside the melting furnace is 0.5MPa; atomization pressure is 7MPa. The atomized metal powder is sieved and classified, and the metal powder with a mesh number of 200-325 is used as the raw material powder for additive manufacturing.

[0036] (2) Before additive manufacturing, the metal powder was dried in a vacuum oven for 12 hours at a drying temperature of 120°C.

[0037] (3) Perform additive manufacturing printing on the above-mentioned dried high...

Embodiment 3

[0040] (1) SLM prints single-phase FCC high-entropy alloys. The components of single-phase FCC high-entropy alloys are: Co 33at.%, Cr33at.%, Ni 33at.%.

[0041] Additive manufacturing of high-entropy alloy powder with the above ingredients, the preparation method is gas atomization method, firstly, the prepared metal block is vacuum smelted, and then an inert gas is used for atomization and powder making, and the inert gas used is argon . The specific parameters for melting are: melting temperature: 1550°C; pressure inside the melting furnace is 0.5MPa; atomization pressure is 7MPa. The atomized metal powder is sieved and classified, and the metal powder with a mesh number of 200-325 is used as the raw material powder for additive manufacturing.

[0042] (2) Before additive manufacturing, the metal powder was dried in a vacuum oven for 12 hours at a drying temperature of 120°C.

[0043] (3) Perform additive manufacturing printing on the above dried high-entropy alloy powder....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com