Nitrogen-doped-polymerized porous nano deposition positive electrode material and preparation method and application thereof

A positive electrode material and nano-deposition technology, applied in the direction of positive electrodes, chemical instruments and methods, nickel compounds, etc., can solve the problems of accelerating electrolyte immersion channels, hindering the normal transmission of sodium ions, destroying mechanical integrity, etc., to facilitate commercial applications , Improved recycling performance, high electrical conductivity and high chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

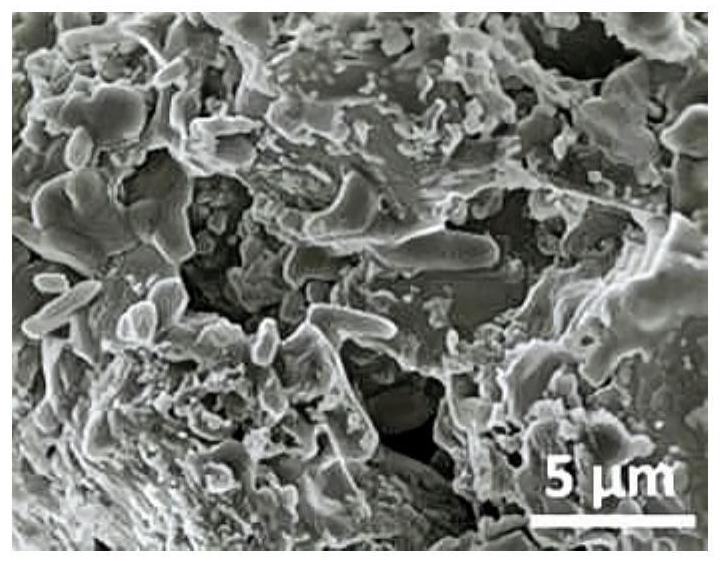

[0040] The nitrogen-doped-polymeric porous nano-deposition cathode material of the present embodiment has a formula of Na 0.8 Li 0.2 Ni 0.7 co 0.05 Mg 0.0 5 mn 0.2 o 2 @0.05NMC-Cu.

[0041] The preparation method of the nitrogen-doped-polymerized porous nano-deposited positive electrode material in this embodiment, the specific steps are as follows:

[0042] (1) Mix 140ml of 0.5mol / L nickel nitrate, 20ml of 1.0mol / L manganese nitrate, 10ml of 0.5mol / L cobalt nitrate, and 20ml of 0.25mol / L magnesium nitrate in a beaker. Add sodium carbonate to an oil bath box, stir, and separate to obtain a nickel-containing precipitate. Mix 80ml of 1.01mol / L sodium hydroxide and 20ml of 1.0mol / L lithium hydroxide to form a sodium-lithium mixture. The sodium-lithium mixture, containing Nickel precipitation is mixed, stirred, dried, sent to a tube furnace at 670°C for calcination for 10 hours, and ball milled to obtain a high-nickel sodium ion positive electrode material Na 0.8 Li 0.2 ...

Embodiment 2

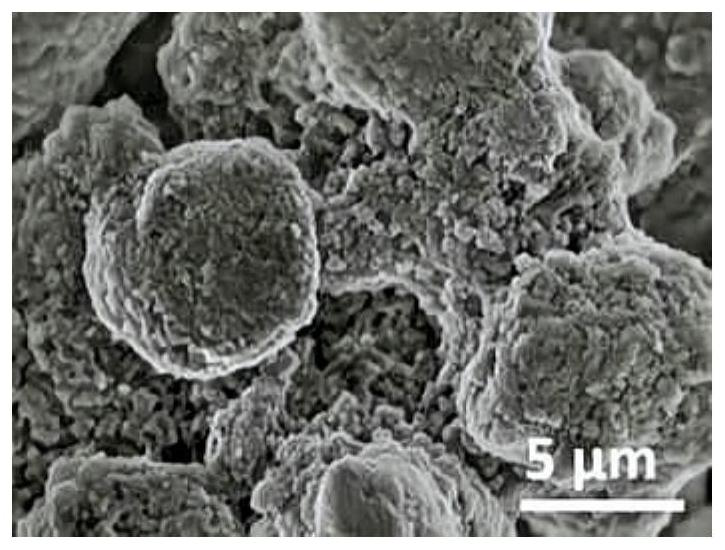

[0046] The nitrogen-doped-polymeric porous nano-deposition cathode material of the present embodiment has a formula of Na 0.75 Li 0.25 Ni 0.60 co 0.025 Mg 0.025 mn 0.35 o 2 @0.025NMC-Cu.

[0047] The preparation method of the nitrogen-doped-polymerized porous nano-deposited positive electrode material in this embodiment, the specific steps are as follows:

[0048] (1) Mix 120ml of 0.5mol / L nickel sulfate, 35ml of 1.0mol / L manganese sulfate, 5ml of 0.5mol / L cobalt sulfate, and 10ml of 0.25mol / L magnesium sulfate in a beaker, and place the beaker at 55°C In an oil bath, add sodium carbonate, stir, and separate to obtain a nickel-containing precipitate. Mix 75ml of 1.01mol / L sodium hydroxide and 25ml of 1.0mol / L lithium hydroxide to form a sodium-lithium mixture. The sodium-lithium mixture, nickel-containing Precipitate, mix, stir, dry, send to a tube furnace at 670°C for calcination for 10 hours, and ball mill to obtain the high-nickel sodium ion positive electrode materi...

Embodiment 3

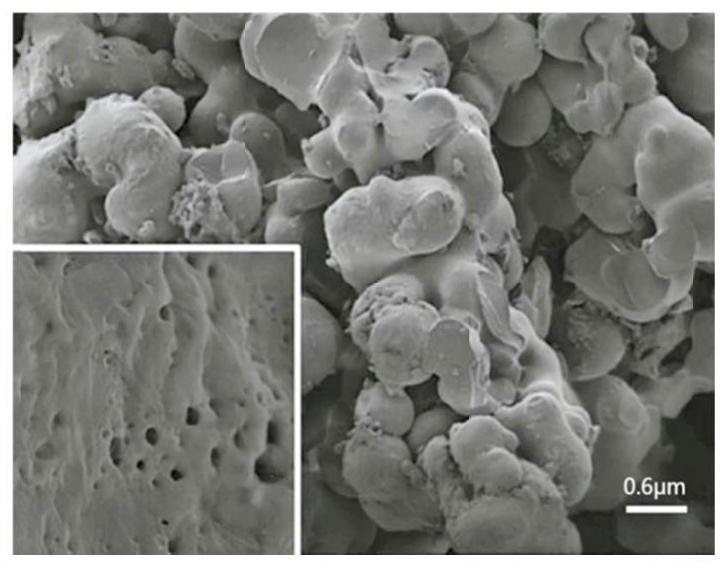

[0052] The nitrogen-doped-polymeric porous nano-deposition cathode material of the present embodiment has a formula of Na 0.88 Li 0.12 Ni 0.68 co 0.065 Al 0.05 Mo 0.023 mn 0.182 o 2 @0.0625NMC-Cu.

[0053] The preparation method of the nitrogen-doped-polymerized porous nano-deposited positive electrode material in this embodiment, the specific steps are as follows:

[0054] (1) 0.85mol / L nickel sulfate of 80ml, 1.3mol / L manganese sulfate of 14ml, 0.65mol / L cobalt sulfate of 10ml, 0.5mol / L aluminum chloride of 10ml, 0.74mol / L ammonium molybdate of 3ml Mix in a beaker, place the beaker in an oil bath at 60°C, add sodium carbonate, stir, and separate to obtain a nickel-containing precipitate, mix 195ml of 0.45mol / L sodium acetate and 20ml of 0.61mol / L lithium hydroxide to prepare sodium Lithium mixture, mixing sodium-lithium mixture and nickel-containing precipitation, stirring, drying, sending to a tube furnace at 730°C for sintering for 8 hours, and ball milling to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com