Preparation method of polystyrene resin-based spherical activated carbon

A polystyrene resin, spherical activated carbon technology, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of high cross-linking degree on the surface of phenolic resin balls, large pores of resin balls, cracking reaction, etc. Low cost of environmental protection treatment, low cost of preparation, and the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

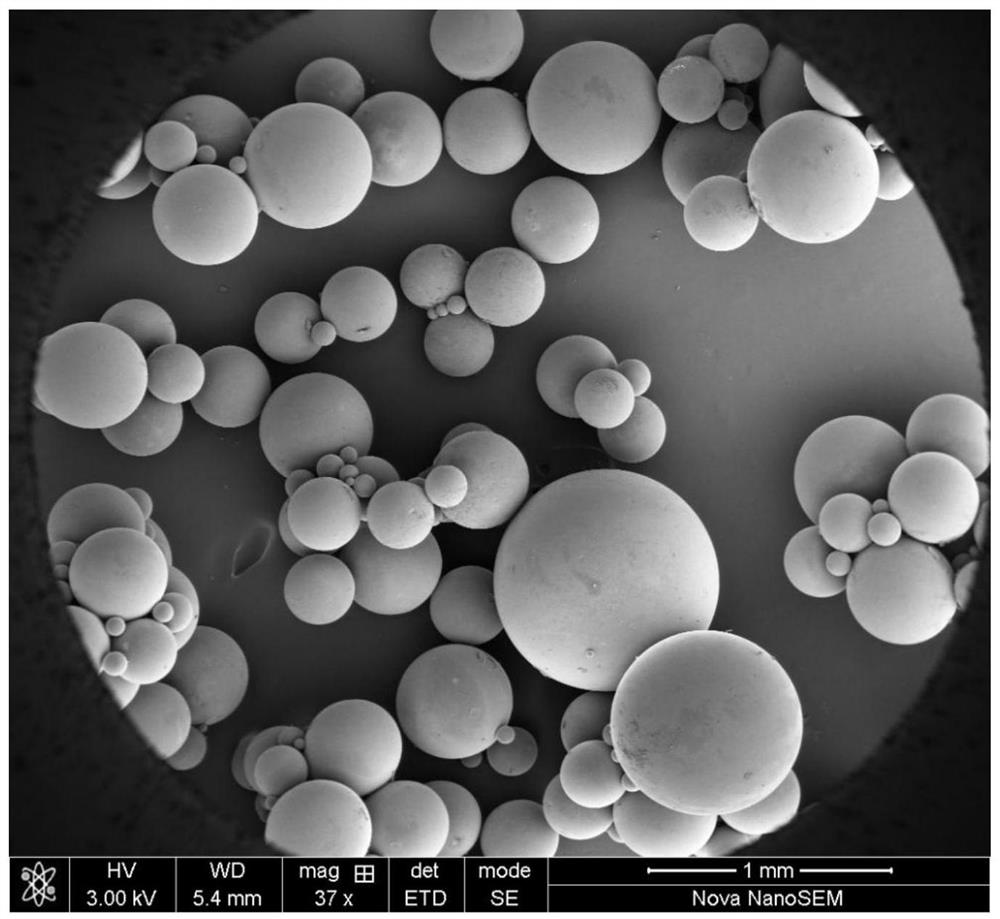

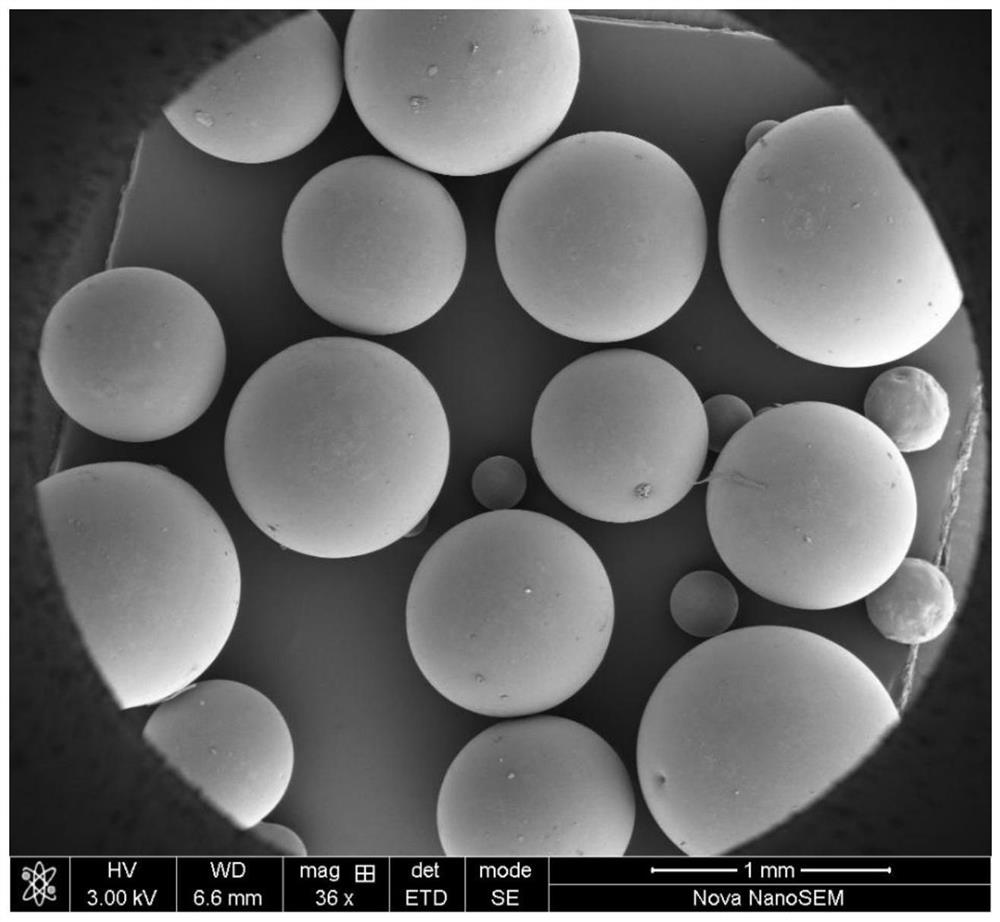

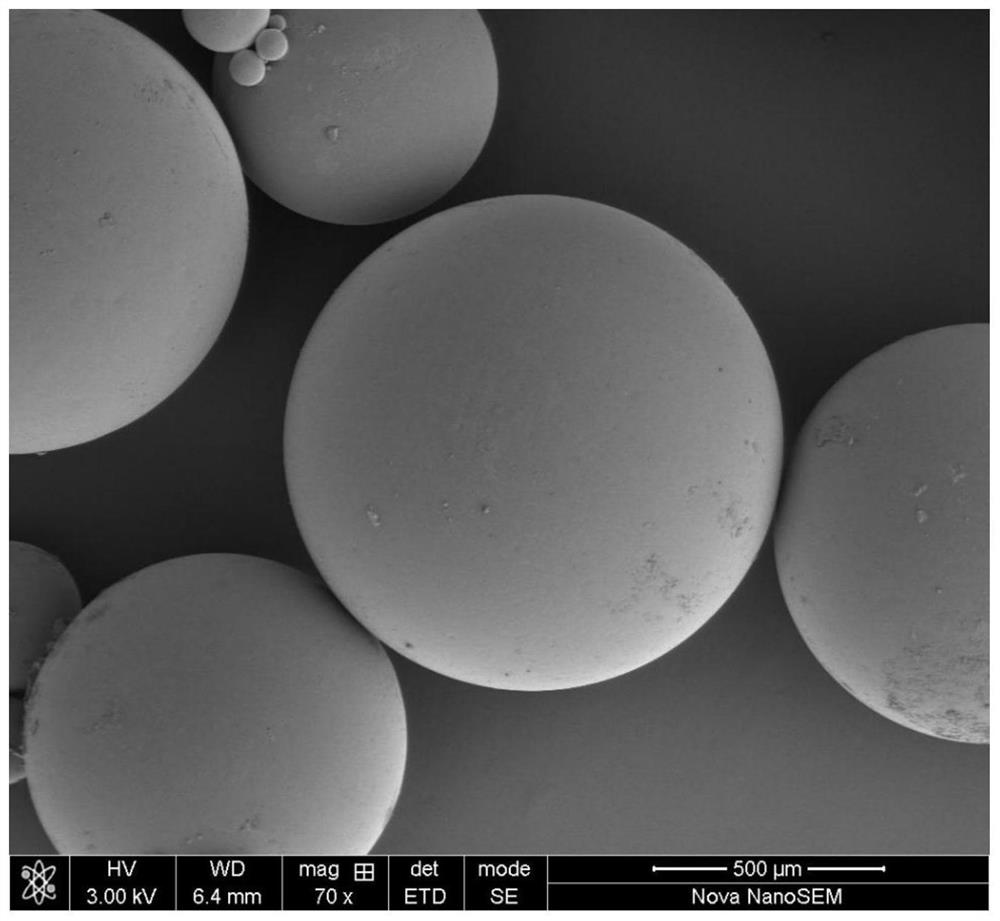

[0036] Using styrene as raw material, o-divinylbenzene as cross-linking agent, polyvinyl alcohol as surfactant, BPO as initiator, deionized water as dispersant, keep the temperature at 85°C and 300r / min for 4h, Polystyrene resin balls were prepared. Among them, the masses of styrene, ortho-divinylbenzene, polyvinyl alcohol, BPO, and deionized water are 40 g, 20 g, 1 g, 2 g, and 120 g, respectively. The average spherical diameter of the produced polystyrene resin balls was 520 µm. By increasing the content of the ortho-divinylbenzene crosslinking agent, the prepared polystyrene resin balls still maintain a complete spherical structure after being oxidized and infused at 350 °C. At a heating rate of 0.15°C / min, the oxidized polystyrene resin balls were raised from room temperature to 950°C in a nitrogen atmosphere and carbonized for 3 hours. The anti-vibration strength was 98.9%, and the average ball diameter was 0.5mm. The specific surface area is 830m 2 / g, S and N, and pol...

Embodiment 2

[0038] Using styrene as raw material, o-divinylbenzene as cross-linking agent, polyvinyl alcohol as surfactant, BPO as initiator, deionized water as dispersant, keep the temperature at 85°C and 300r / min for 4h, Polystyrene resin balls were prepared. Among them, the masses of styrene, ortho-divinylbenzene, polyvinyl alcohol, BPO, and deionized water are 40 g, 20 g, 1 g, 2 g, and 120 g, respectively. The average spherical diameter of the produced polystyrene resin balls was 520 µm. By increasing the content of the ortho-divinylbenzene crosslinking agent, the prepared polystyrene resin balls still maintain a complete spherical structure after being oxidized and infused at 350 °C. At a heating rate of 0.05°C / min, the oxidized polystyrene resin balls were raised from room temperature to 950°C in a nitrogen atmosphere and carbonized for 3 hours. The anti-vibration strength was 98.2%, and the average ball diameter was 0.5mm. The specific surface area is 1230m 2 / g, S and N, and po...

Embodiment 3

[0040] Using styrene as raw material, para-propyl styrene as crosslinking agent, polyvinyl alcohol as surfactant, BPO as initiator, and deionized water as dispersant, keep the temperature at 85°C and 300r / min for 4 hours. Polystyrene resin balls were prepared. Among them, the masses of styrene, p-propyl styrene, polyvinyl alcohol, BPO, and deionized water are 40g, 20g, 1g, 2g, and 120g, respectively. The average spherical diameter of the produced polystyrene resin balls was 520 µm. The prepared polystyrene resin ball still maintains a complete spherical structure after being oxidized and infused at 350°C. At a heating rate of 0.05°C / min, the oxidized polystyrene resin balls were raised from room temperature to 950°C in a nitrogen atmosphere and carbonized for 3 hours. The anti-vibration strength was 99.3%, and the average ball diameter was 0.5mm. The specific surface area is 1470m 2 / g, S and N, and polystyrene resin-based spherical activated carbon with ash content of 0% (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com