Sequencing batch reaction process and device for single-step denitrification without moving parts

A sequential batch reaction and no motion technology, applied in the field of resources and environment, can solve the problems of low shock load adaptability, limited on-site personnel strength, large water quality changes, etc., to achieve strong adaptability, low power supply line requirements, and installed low power effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

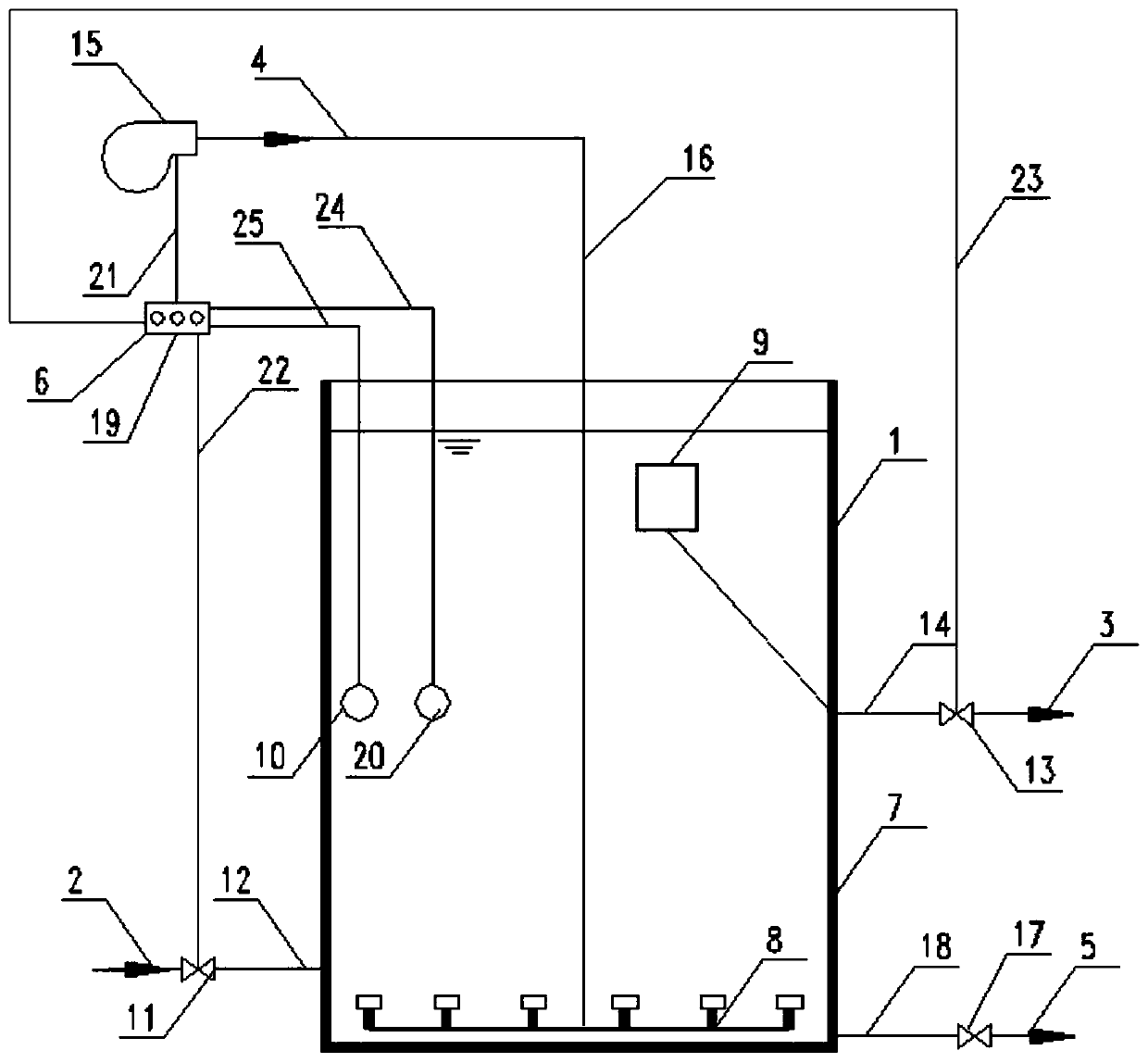

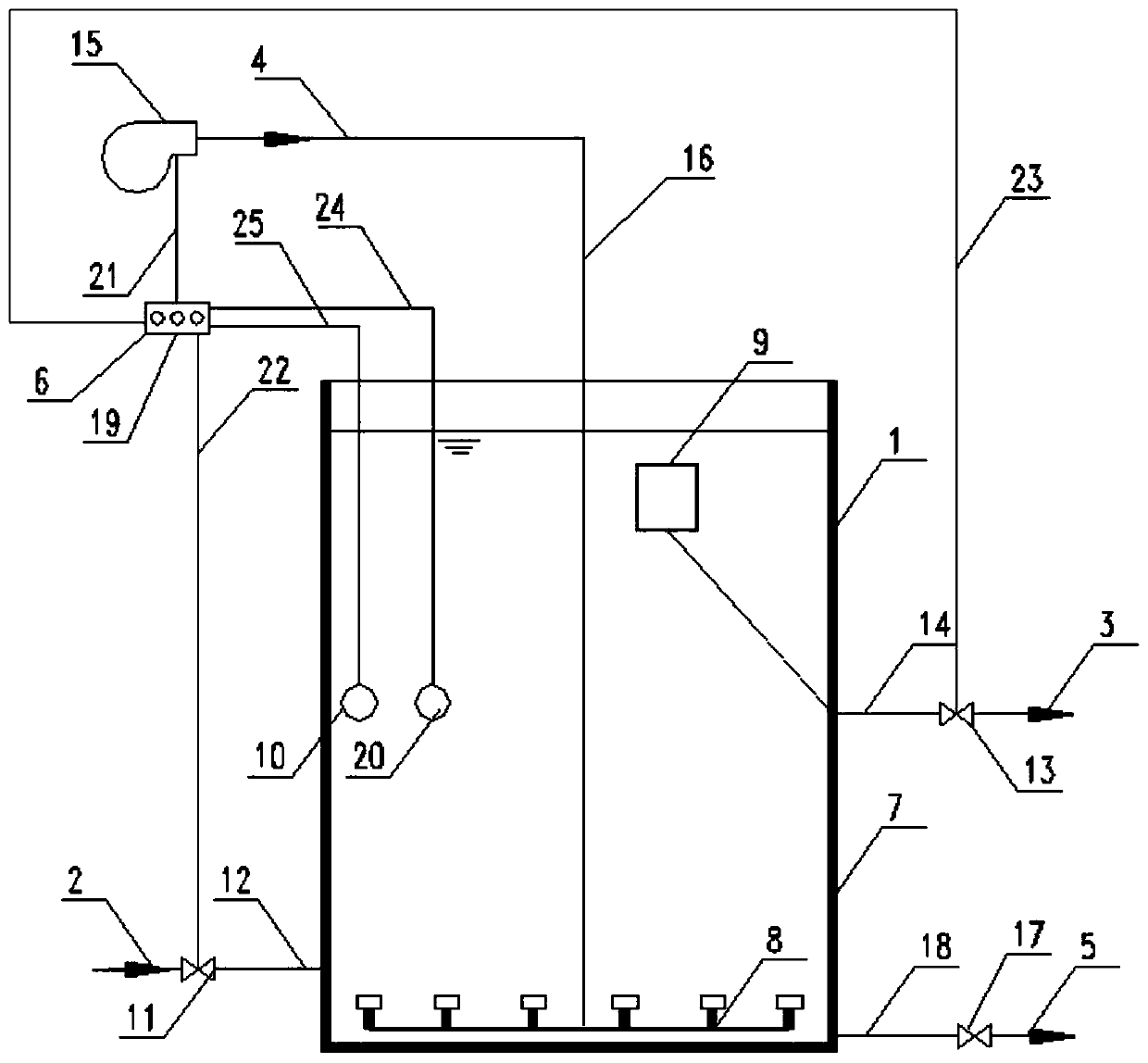

[0036] according to figure 1 As shown, the present invention adopts a sequence batch reaction process and device for single-step denitrification without mechanical stirring, without decanter, and without moving parts in the pool, and the technical scheme is as follows:

[0037] (1) Control the air blower 15 by PLC to realize limited aeration or intermittent aeration, which is used to replace the mechanical stirring device;

[0038] (2) The decanter is replaced by a combination of a fixed water collecting device 9 and a water outlet device controlled by PLC;

[0039] (3) Each cycle includes 3-stage modes of water inflow / outflow, aeration, and sedimentation, or 5-stage modes of water inflow, aeration, sedimentation, water outflow, and idle, etc., so that the water can be purified repeatedly;

[0040] (4) The aeration stage is divided into three sub-stages: the early stage (mixing stage), the middle stage (carbonization and simultaneous nitrification / denitrification stage), and ...

Embodiment 2

[0059] The structure, connection relationship and process of Example 2 are the same as those of Example 1, and the sequential batch reaction process and device for single-step denitrification without mechanical stirring, no decanter, and no moving parts in the pool of Example 2 are used. The typical treatment effect of an organic wastewater is shown in the table below:

[0060] project COD BOD TP Ammonia nitrogen SS Influent (mg / L) 600 300 4.0 60 300 Effluent (mg / L) 40 10 0.5 0.9 30 Removal rate 93% 97% 87% 98% 90%

Embodiment 3

[0062] Embodiment 3 is the same as Embodiment 1 except that a dissolved oxygen or ORP sensor 10 is provided below the liquid level in the reactor main body 1 . The single-step denitrification sequencing batch reaction process and device without mechanical stirring, without decanter, and without moving parts in the pool of Example 3 are used for sewage in a certain village. The typical treatment effect is shown in the following table:

[0063] project COD BOD TP Ammonia nitrogen SS Influent (mg / L) 100 50 4.0 30 180 Effluent (mg / L) 35 15 1.0 5 20 Removal rate 65% 70% 75% 83% 89%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com