Aeration disc and preparation method thereof

An aeration pan and microwave curing technology, which is applied in water aeration, chemical instruments and methods, water treatment parameter control, etc., can solve the problems of limited improvement of the compressive strength of the aeration pan and long curing time, and shorten the curing time. Time, improve production efficiency, improve the effect of compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

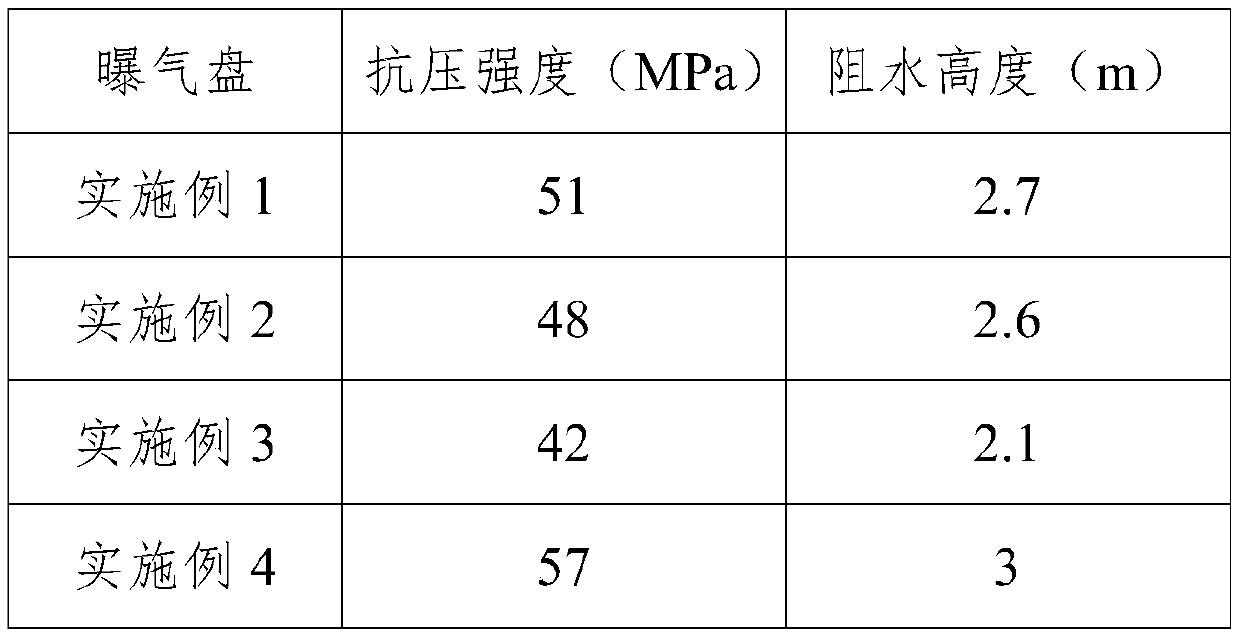

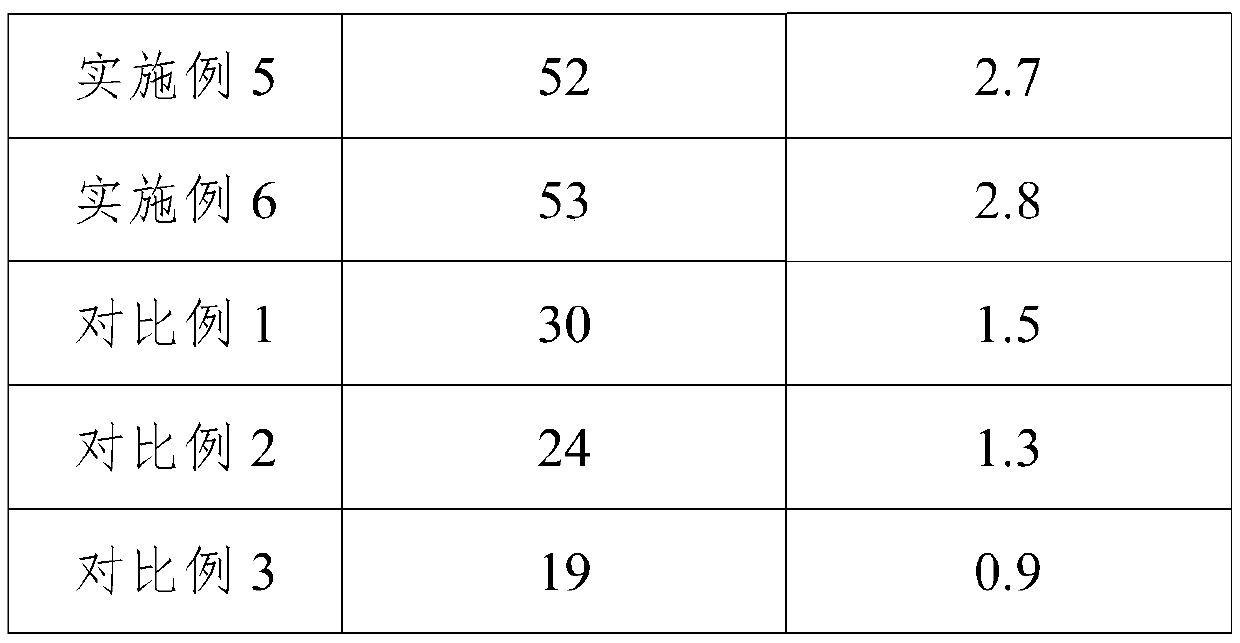

Examples

Embodiment 1

[0038] This embodiment provides a method for preparing an aeration tray, comprising the following steps:

[0039] 1) Add 0.8kg of ethylenediamine to 5kg bisphenol A type modified epoxy resin (epoxy value is 0.09-0.14mol / 100g, weight average molecular weight is 500), to obtain glue (the first mixed material);

[0040] 2) adding the glue solution to 100 kg of silica sand with a particle diameter of 0.06 mm, stirring and mixing evenly to obtain the second mixed material;

[0041] 3) Add the second mixed material into a steel mold, use a hydraulic press with a model number of YAW4605, pressurize the second mixed material at 20°C, and pressurize the second mixed material at a pressure of 3000N / cm 2 , the pressurization time is 1min, and then the pressure is removed to obtain the rough embryo of the aeration disc;

[0042] 4) Perform microwave curing on the rough embryo of the aeration disc. The microwave curing temperature is 130° C., and the microwave curing time is 8 minutes. Af...

Embodiment 2

[0044] This embodiment provides a method for preparing an aeration tray, comprising the following steps:

[0045] 1) Add 1kg of methylol ethylenediamine to 7kg bisphenol A type modified epoxy resin (epoxy value 0.09-0.14mol / 100g, weight-average molecular weight is 500), to obtain glue (the first mixed material );

[0046] 2) Add the glue solution to 100 kg of silica sand with a particle diameter of 1.2 mm, stir and mix evenly to obtain the second mixed material;

[0047] 3) Add the second mixed material into a steel mold, use a hydraulic press with a model number of YAW4605, pressurize the second mixed material at 20°C, and pressurize the second mixed material at a pressure of 3000N / cm 2 , the pressurization time is 1min, and then the pressure is removed to obtain the rough embryo of the aeration disc;

[0048] 4) Perform microwave curing on the rough embryo of the aeration disc, the microwave curing temperature is 140° C., the microwave curing time is 3 minutes, and the mol...

Embodiment 3

[0050] This embodiment provides a method for preparing an aeration tray, comprising the following steps:

[0051] 1) Add 2kg of hydroxyethylethylenediamine to 1kg of modified acrylic resin to obtain glue (the first mixed material);

[0052] 2) adding the glue solution to 100 kg of river sand with a particle diameter of 1.2 mm, stirring and mixing evenly to obtain the second mixed material;

[0053] 3) Add the second mixed material into a steel mold, use a hydraulic press with a model number of YAW4605, pressurize the second mixed material at 20°C, and pressurize the second mixed material at a pressure of 2000N / cm 2 , the pressurization time is 5 minutes, and then the pressure is removed to obtain the rough embryo of the aeration disc;

[0054] 4) Perform microwave curing on the rough embryo of the aeration disc. The microwave curing temperature is 80° C., and the microwave curing time is 20 minutes. After microwave curing, the mold is removed to obtain the aeration disc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com