Brush-coating LED transparent primer, and preparation method and application thereof

A transparent primer and brushing technology, applied in primers, coatings, polyester coatings, etc., can solve the problems of poor surface drying and easy sagging, and achieve the effect of improving environmental protection, protecting the environment and good hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

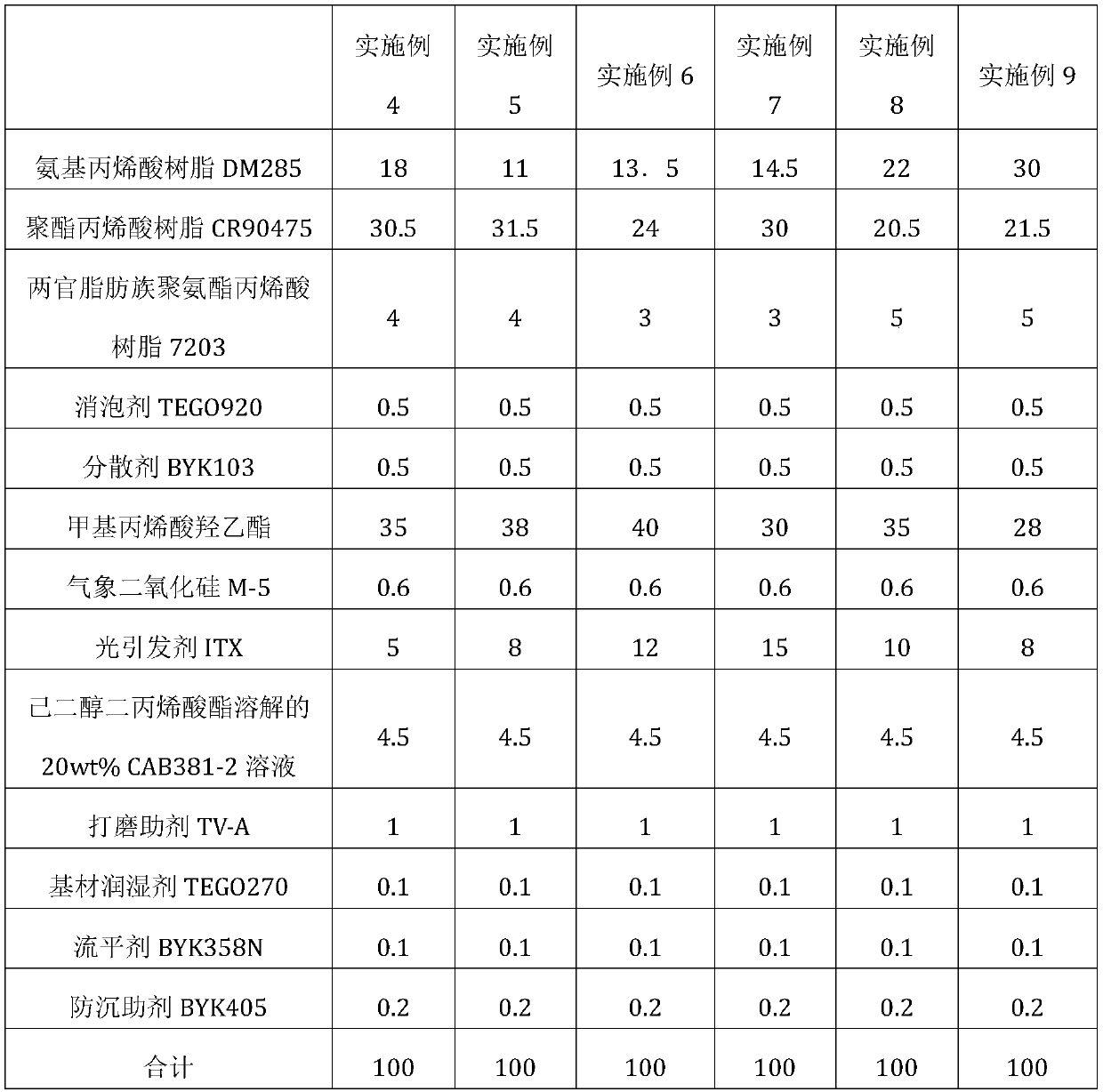

Examples

Embodiment 1

[0063] Embodiment 1: A transparent primer for brushing LEDs, comprising the following components in parts by weight: 18 parts of aminoacrylic resin, 30 parts of polyester acrylic resin, 3 parts of difunctional aliphatic polyurethane acrylic resin, defoamer 0.3 parts, 0.3 parts of dispersant, 25 parts of acrylate monomer, 0.5 part of meteorological silica, 5 parts of photoinitiator, 3 parts of acrylate monomer dissolved CAB solution, 0.5 part of grinding aid; substrate wetting agent 0.05 part, 0.05 part of leveling agent, and 0.1 part of anti-sedimentation additive.

[0064] Wherein, the CAB solution in which acrylate monomers are dissolved is a 20 wt % CAB381-2 solution in which hexanediol diacrylate is dissolved. The defoamer is TEGO920, the dispersant is BYK103, the acrylate monomer is hydroxyethyl methacrylate, the meteorological silica is M-5, the photoinitiator is ITX, the leveling agent is BYK358N, and the anti-sedimentation agent is BYK405 .

[0065] The preparation m...

Embodiment 2

[0069] Embodiment 2: A transparent primer for brushing LEDs, comprising the following components in parts by weight: 20 parts of aminoacrylic resin, 35 parts of polyester acrylic resin, 4 parts of difunctional aliphatic polyurethane acrylic resin, defoamer 0.6 parts, 0.8 parts of dispersant, 35 parts of acrylate monomer, 0.8 part of meteorological silica, 12 parts of photoinitiator, 4 parts of acrylate monomer dissolved CAB solution, 1 part of grinding aid; substrate wetting agent 0.12 parts, 0.11 parts of leveling agent, and 0.15 parts of anti-sedimentation additive.

[0070] Wherein, the CAB solution in which acrylate monomers are dissolved is a 20 wt % CAB381-2 solution in which hexanediol diacrylate is dissolved. The defoamers are TEGO920 and BYK055, and the weight ratio of TEGO920 and BYK055 is 1:1.2. The dispersant is AFCONA4010, the acrylate monomer is propoxylated (2) neopentyl glycol diacrylate, and the meteorological silica is M-5 and AEROSIL R972, wherein the weigh...

Embodiment 3

[0075] Embodiment 3: A kind of LED transparent primer for brushing, comprising the following components: 30 parts of aminoacrylic resin, 20 parts of polyester acrylic resin, 5 parts of difunctional aliphatic polyurethane acrylic resin, 1 part of defoamer, 1 part of dispersant 40 parts of acrylate monomer, 1 part of meteorological silica, 15 parts of photoinitiator, 5 parts of acrylate monomer dissolved CAB solution, 1.5 parts of polishing aid; 0.15 parts of substrate wetting agent, 0.15 parts of leveling agent part, 0.3 part of anti-sedimentation additive.

[0076] Wherein, the CAB solution in which acrylate monomers are dissolved is a 20 wt % CAB381-2 solution in which hexanediol diacrylate is dissolved. The defoamer is BYK055, the dispersant is BYK204, the acrylate monomer is hydroxyethyl methacrylate, the meteorological silica is AEROSIL R972, the photoinitiator is DETX, the leveling agent is BYK361N, and the anti-sedimentation additive is 6900- 20X.

[0077] The preparat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com