High-temperature-resistant anticorrosive primer for surface of metal structure and preparation method thereof

An anti-corrosion primer and metal structure technology, applied in primers, anti-corrosion coatings, fire-retardant coatings, etc., can solve the problems of difficult detection of corrosion in hidden places, difficult maintenance and repair, and easy rust of the coated object, so as to achieve long-term anti-corrosion. Rust anti-corrosion effect, good effect, no rust effect of coating film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

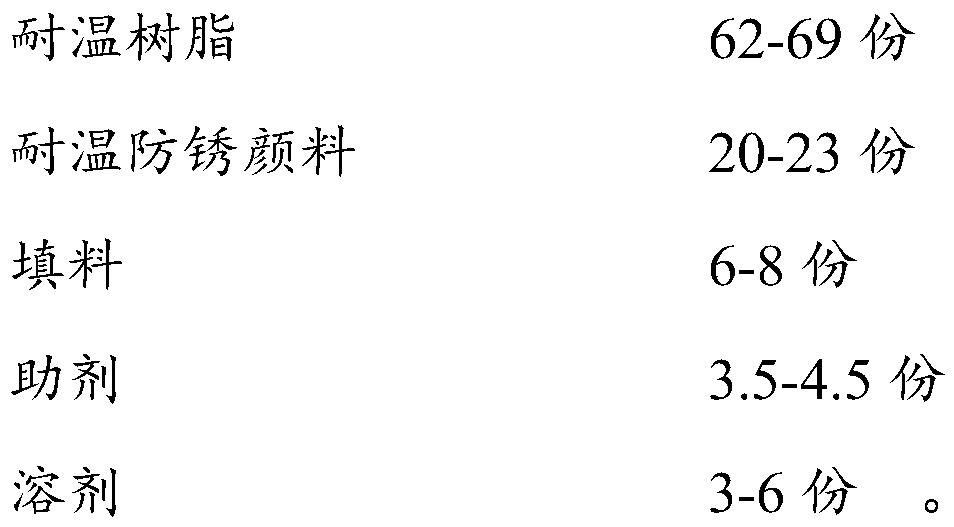

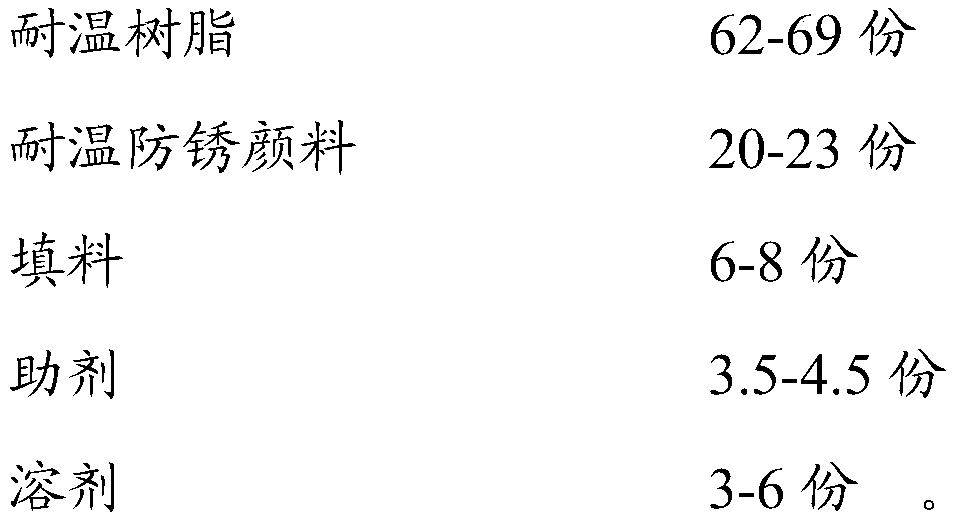

Method used

Image

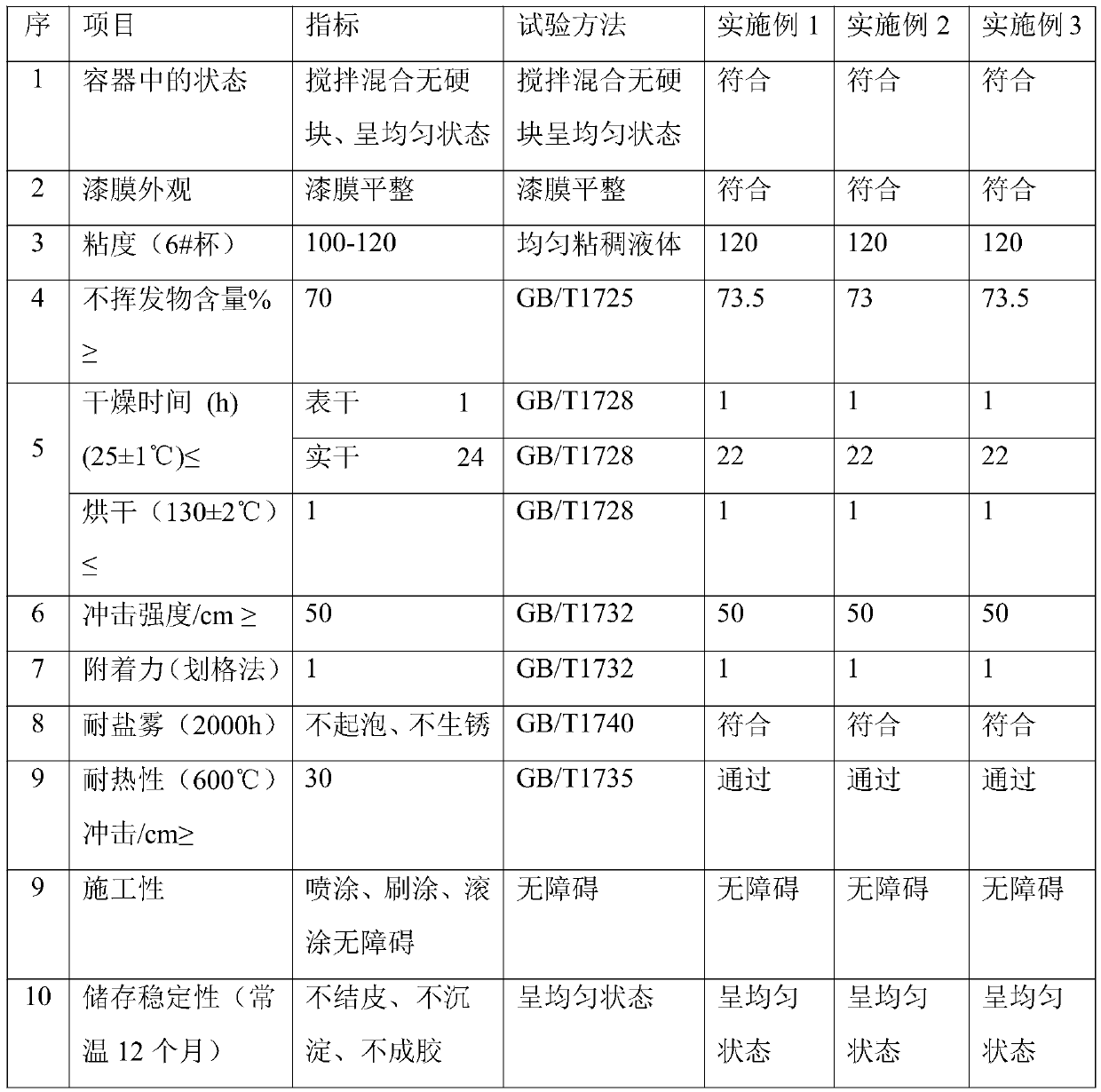

Examples

Embodiment 1

[0043] (1) Mix 20kg of xylene, 5kg of 833-606 dispersant, 6kg of HX-2080 defoamer, and 3kg of R972 fumed silica into the batching tank in turn, and put CIMA240 anti-sedimentation thixotropic agent 19 under stirring ㎏, 1#WET600 high temperature resistant resin 290㎏, 2#DSSZ20 resin 30㎏, PE550-1000 mesh glass powder 330kg, F9900M ferromanganese black 86㎏, 800 mesh graphite powder 8㎏, nano-scale talcum powder 50kg, 1250 mesh Precipitated barium sulfate 12kg, 500 mesh mica iron oxide 55kg, stirred at high speed (800-850 rpm) for 30-40 minutes, fully stirred and mixed evenly;

[0044](2) Sand mill and disperse the uniformly stirred mixture and stop sand milling and dispersing when it reaches the specified fineness (less than or equal to 50 microns), and input the above mixture (914 kg) into the paint mixing tank.

[0045] (3) Batch 12kg of xylene, 6kg of HS806 adhesion promoter, and 6kg of butyl acetate into the batching tank in sequence, and put in 62kg of N110 aluminum powder slur...

Embodiment 2

[0053] (1) Mix 20kg of xylene, 5kg of 833-606 dispersant, 6kg of HX-2080 defoamer, and 3kg of R972 fumed silica into the batching tank in turn, and put CIMA240 anti-sedimentation thixotropic agent 19 under stirring ㎏, 3#W90A high temperature resistant resin 290㎏, 2#DSSZ20 resin 30㎏, PE550-1000 mesh glass powder 330kg, F9900M ferromanganese black 86㎏, 800 mesh graphite powder 8㎏, nano-scale talcum powder 50kg, 1250 mesh Precipitated barium sulfate 12kg, 500 mesh mica iron oxide 55kg, stirred at high speed (800-850 rpm) for 30-40 minutes, fully stirred and mixed evenly;

[0054] (2) Sand mill and disperse the evenly stirred mixture and stop sand milling and dispersing when the specified fineness (less than or equal to 50 microns) is reached, and input the above mixture (914kg in total) into the paint mixing tank;

[0055] (3) Batch 12 kg of xylene, 6 kg of HS806 adhesion promoter, and 6 kg of butyl acetate into the batching tank in sequence, and put 62 kg of N110 aluminum powder...

Embodiment 3

[0063] (1) Mix 20kg of xylene, 5kg of 833-606 dispersant, 6kg of HX-2080 defoamer, and 3kg of R972 fumed silica into the batching tank in turn, and put CIMA240 anti-sedimentation thixotropic agent 19 under stirring ㎏, 4#SH-961 high temperature resistant resin 290㎏, 2#DSSZ20 resin 30㎏, PE550-1000 glass powder 330㎏, F9900M ferromanganese black 86㎏, 800 mesh graphite powder 8㎏, nano-scale talc powder 50㎏, 1250 12kg of precipitated barium sulfate, 55kg of mica iron oxide of 500 mesh, stirred at high speed (800-850 rpm) for 30-40 minutes, fully stirred and mixed evenly;

[0064] (2) Sand mill and disperse the evenly stirred mixture and stop sand milling and dispersing when the specified fineness (less than or equal to 50 microns) is reached, and input the above mixture (914kg in total) into the paint mixing tank;

[0065] (3) Add 12kg of xylene, 6kg of HS806 adhesion promoter, and 6kg of butyl acetate in sequence, and put in 62kg of N110 aluminum powder slurry (86kg in total) under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com