Water blocking releasing agent for oil and gas reservoirs and preparation method thereof

A technology for water-blocking agents and oil and gas reservoirs, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of high cost of water-blocking agents, environmental pollution, complex production processes, etc., and increase the relative permeability of oil phase , good surface activity and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

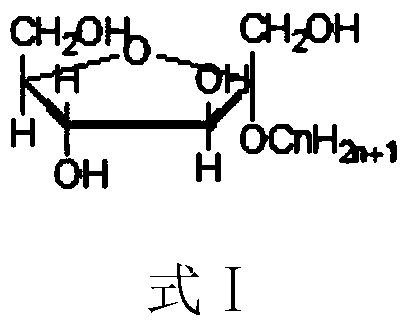

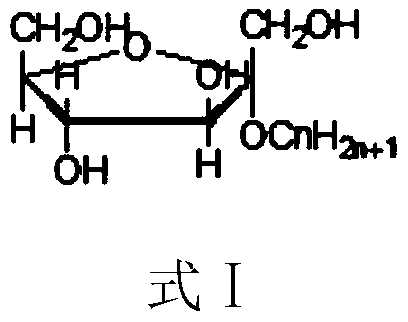

[0036] Example 1 Preparation of dodecyl fructoside:

[0037] Step 1: Add 6 mol of n-dodecyl alcohol and 1 mol of fructose (slowly and in batches) into the reactor, heat up to 90°C, and after stirring evenly, add the catalyst concentrated sulfuric acid and phosphoric acid (volume ratio 1:1), the amount added It is 0.1% of the total system mass, and the temperature is raised while stirring, and the appropriate time and pressure are controlled until the reactant in the four-necked flask changes from a white turbid liquid to a clear liquid, and the distillate is collected.

[0038] Step 2: After reacting for a period of time, take out a certain volume of reaction mixed liquid, neutralize it to pH 7, add Fehling's reagent to the mixed liquid, and heat it in a boiling water bath for 2 minutes. If many brick red precipitates are formed, it means synthesis The reaction is not completely over, and the reaction should be continued until a small amount of brick-red precipitate is formed...

Embodiment 2

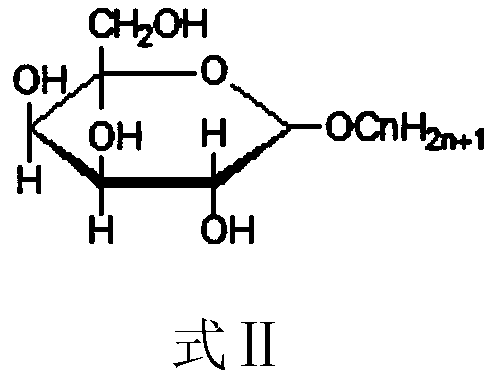

[0043] Example 2 Preparation of tetradecyl lactoside:

[0044]Step 1: Add 8 mol of n-tetradecyl alcohol and 1 mol of galactose (slowly and in batches) into the reactor, heat up to 125°C, and after stirring evenly, add catalyst concentrated sulfuric acid and phosphoric acid (volume ratio 1:1), add The amount is 0.5% of the total system mass, and the temperature is raised while stirring, and the appropriate time and pressure are controlled until the reactant in the four-necked flask changes from a white turbid liquid to a clear liquid, and the distillate is collected.

[0045] Step 2: After reacting for a period of time, take out a certain volume of reaction mixed liquid, neutralize it to pH 8, add Fehling's reagent to the mixed liquid, and heat it in a boiling water bath for 2 minutes. If a lot of brick red precipitates are formed, it means synthesis The reaction is not completely over, and the reaction should be continued until a small amount of brick-red precipitate is form...

Embodiment 3

[0048] Example 3 Chemical agents used to release reservoir water lock effect during oil and gas field development

[0049] include:

[0050] 0.01 wt% cationic polyacrylamide, the molecular weight of the cationic polyacrylamide is between 2 million and 3 million;

[0051] Lauryl glucoside 73.99wt%;

[0052] Ethylene glycol butyl ether 25wt%;

[0053] 25-40nm nanocrystalline cellulose 1wt%.

[0054] Preparation method: mix cationic polyacrylamide, dodecyl glucoside, ethylene glycol butyl ether, and 25-40nm nanocrystalline cellulose uniformly according to the proportion.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com