Application of spiral crystal selector in preparation of thermocouple wire material, thermocouple wire and application of thermocouple wire

A technology of spiral crystal selector and galvanic couple, which is applied in the field of materials, can solve the problems of measurement accuracy error and interference measurement accuracy, and achieve the effects of reducing internal resistance, improving temperature measurement accuracy, and small internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

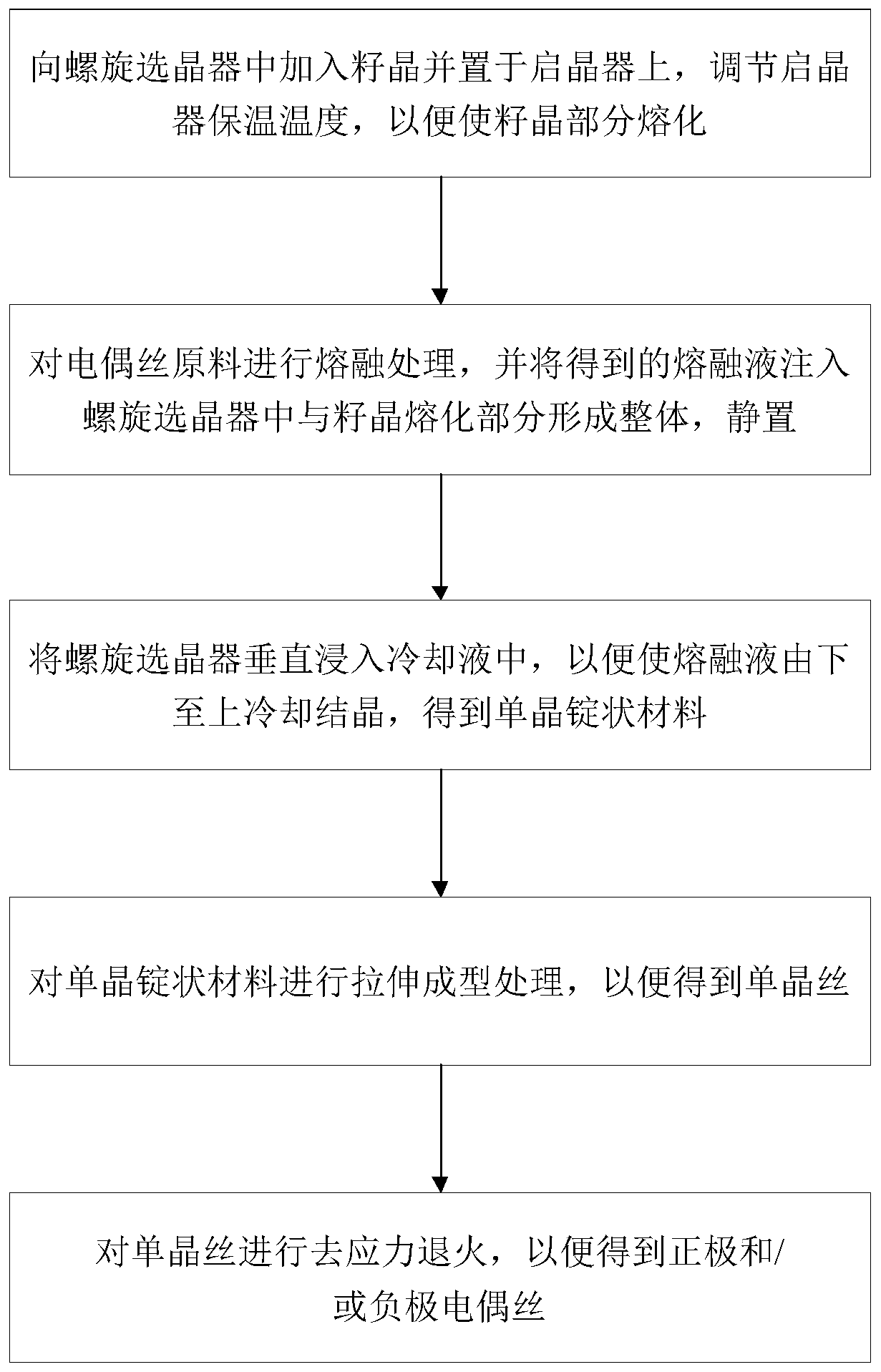

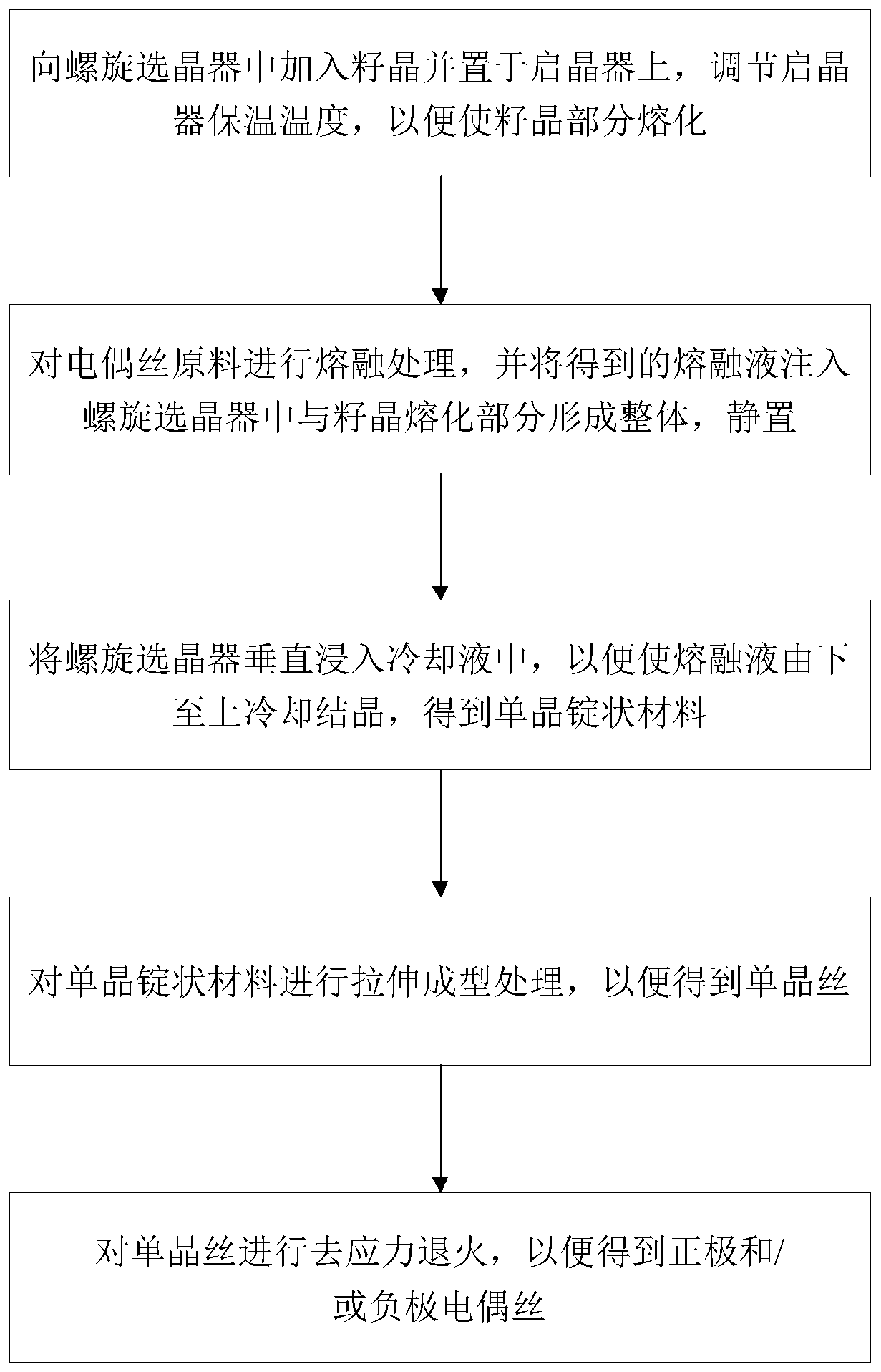

[0052] According to the second aspect of the present invention, the present invention provides a galvanic wire. According to an embodiment of the present invention, such as figure 1 As shown, the preparation method of the galvanic couple wire includes: (1) adding a seed crystal to a spiral crystal selector and placing it on the crystal starter, and adjusting the temperature of the crystal starter to partially melt the seed crystal; (2) The raw material of the galvanic wire is melted, and the obtained molten liquid is injected into the spiral crystal selector to form a whole with the melting part of the seed crystal, and stand still; (3) The spiral crystal selector obtained in step (2) is vertically immersed in the cooling liquid , In order to cool and crystallize the molten liquid from bottom to top to obtain a single crystal ingot material; (4) stretch the single crystal ingot material to obtain a single crystal wire; (5) perform stress relief annealing on the single crystal w...

Embodiment 1

[0069] An ultra-long T-type single crystal couple wire, and its preparation method includes the following steps:

[0070] 1) Preparation of positive and negative single crystal ingot materials:

[0071] 2.75Kg pure copper powder and 2.25Kg pure nickel powder are uniformly mixed as negative electrode material; 5Kg pure copper powder is used as positive electrode material.

[0072] The seed crystals of the positive electrode and the negative electrode material are prepared separately, and the seed crystals are respectively installed on the crystal starter in the spiral crystal selector. The temperature of the crystal starter is adjusted to partially melt the seed crystals to form a solid-liquid paste zone, and the temperature is maintained for 30 minutes.

[0073] Smelt the negative electrode raw materials in a crucible at 1300°C to obtain a molten alloy melt; after the crystal starter is kept warm, pour the molten superalloy melt into the spiral crystal selector to form a whole with th...

Embodiment 2

[0078] An ultra-long J-type single crystal couple wire, and its preparation method includes the following steps:

[0079] 1) Preparation of positive and negative single crystal ingot materials:

[0080] 2.75Kg pure copper powder and 2.25Kg pure nickel powder are uniformly mixed as negative electrode material; 5Kg pure iron powder is used as positive electrode material.

[0081] The seed crystals of the positive electrode and the negative electrode material are prepared separately, and the seed crystals are respectively installed on the crystal starter in the spiral crystal selector. The temperature of the crystal starter is adjusted to partially melt the seed crystals to form a solid-liquid paste zone, and the temperature is maintained for 30 minutes.

[0082] Smelt the negative electrode raw materials in a crucible at 1300°C to obtain a molten alloy melt; after the crystal starter is kept warm, pour the molten superalloy melt into the spiral crystal selector to form a whole with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com