Micro-lens hot reflux process analysis method in complex phase change characteristic fluid environment

A technology of process analysis and thermal reflow, applied in computer-aided design, design optimization/simulation, calculation, etc., can solve problems such as optimizing experimental parameters, difficult molding process, unfavorable, etc., to achieve optimized experimental parameters, precise manufacturing, processing shape controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] In this example, the technological process of PDMS-assisted thermal reflow processing cylindrical microlens is selected for simulation, and its forming process and forming mechanism are analyzed.

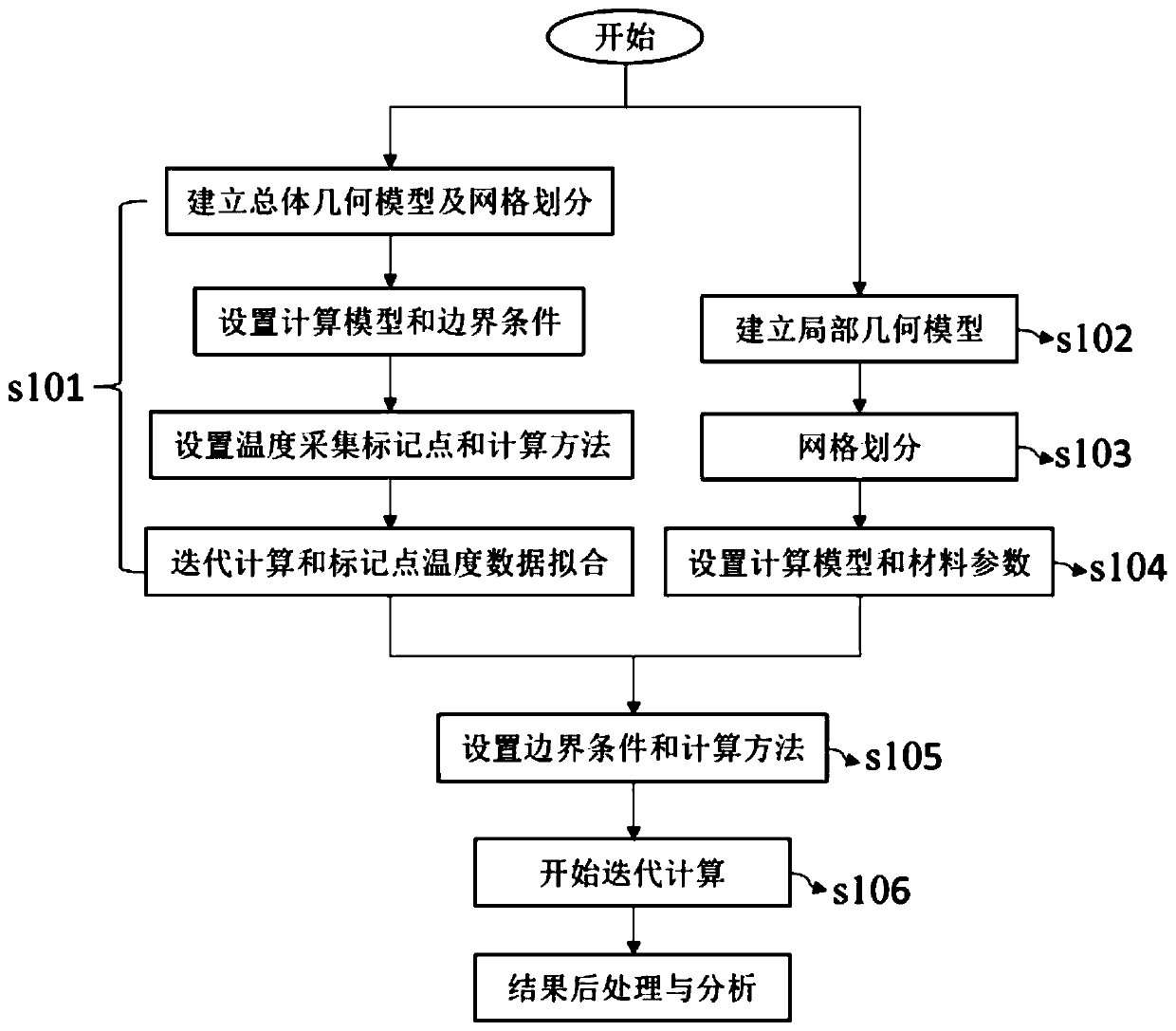

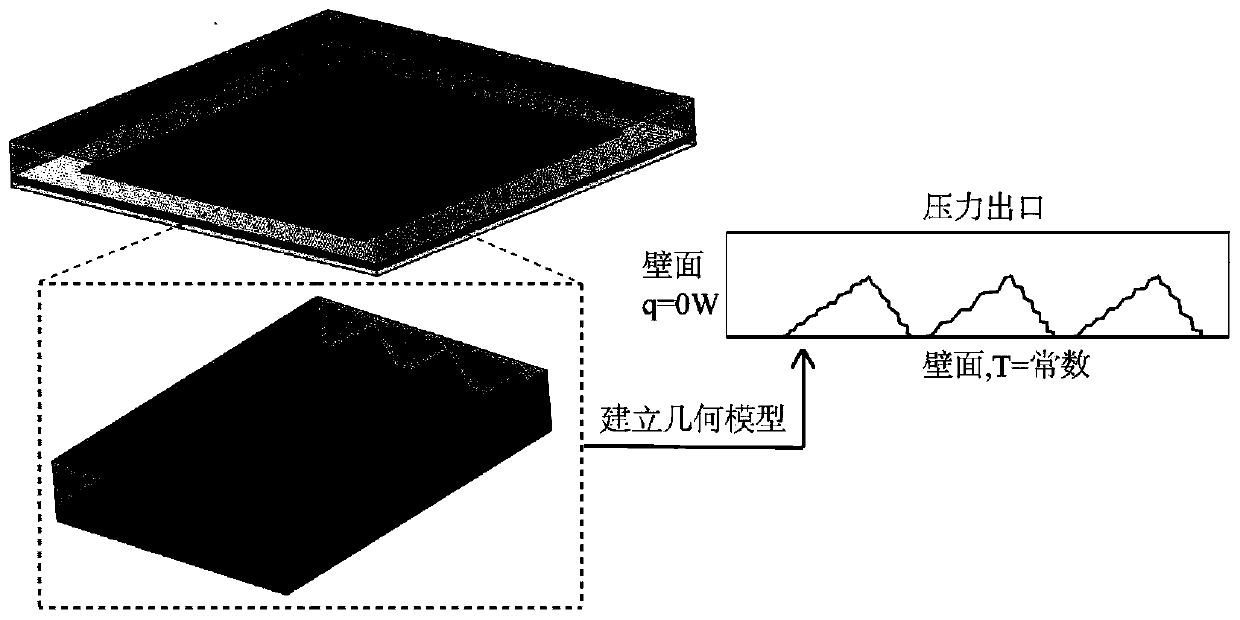

[0053] Such as figure 1 As shown, the microlens thermal reflow process analysis method with complex phase transition characteristics disclosed by the examples of the present invention is used for the process simulation of PDMS assisted thermal reflow processing cylindrical microlens. The specific implementation steps are as follows:

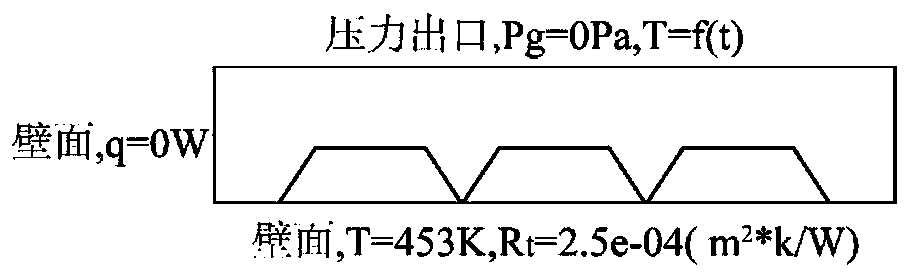

[0054] Step 1 (s101): According to the entire flow area of the two-phase fluid involved in the thermal reflux experiment, an overall three-dimensional geometric model is established. The overall geometric model is a cuboid, whose surface is the calculation boundary, and its interior is the calculation domain ;Use the simulation calculation pre-processing software to divide the grid, set the preliminary boundary conditions and the properties of...

Embodiment 2

[0079] In this example, the technological process of PDMS-assisted heat reflow processing of inclined cylindrical microlenses is selected for simulation, and its forming process and forming mechanism are analyzed.

[0080] The microlens thermal reflow process analysis method with complex phase change characteristics disclosed in this example is used for the process simulation analysis of PDMS-assisted thermal reflow processing of inclined cylindrical microlenses. The specific implementation steps are basically the same as the corresponding steps in Example 1. Wherein, the geometric model in step 2 is replaced with the simplified model of the simulation calculation of the inclined cylindrical lens, such as Figure 7 shown. The rest of the settings are unchanged. The contour evolution diagram of reflow and the velocity vector diagram when the time is 0.1s are as follows: Figure 8 with Figure 9 shown. The comparison between the simulation results and the experimental result...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com