Smoked roasting based preparation method for cured streaky pork

A technology for smoking bacon and pork belly, which is applied in separation methods, chemical instruments and methods, and meat/fish preservation, etc. It can solve the problems of not bright enough color, burnt yellow, and inconvenient movement of baking racks, etc., and achieve a long-lasting meat flavor. , the effect of burnt yellow color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

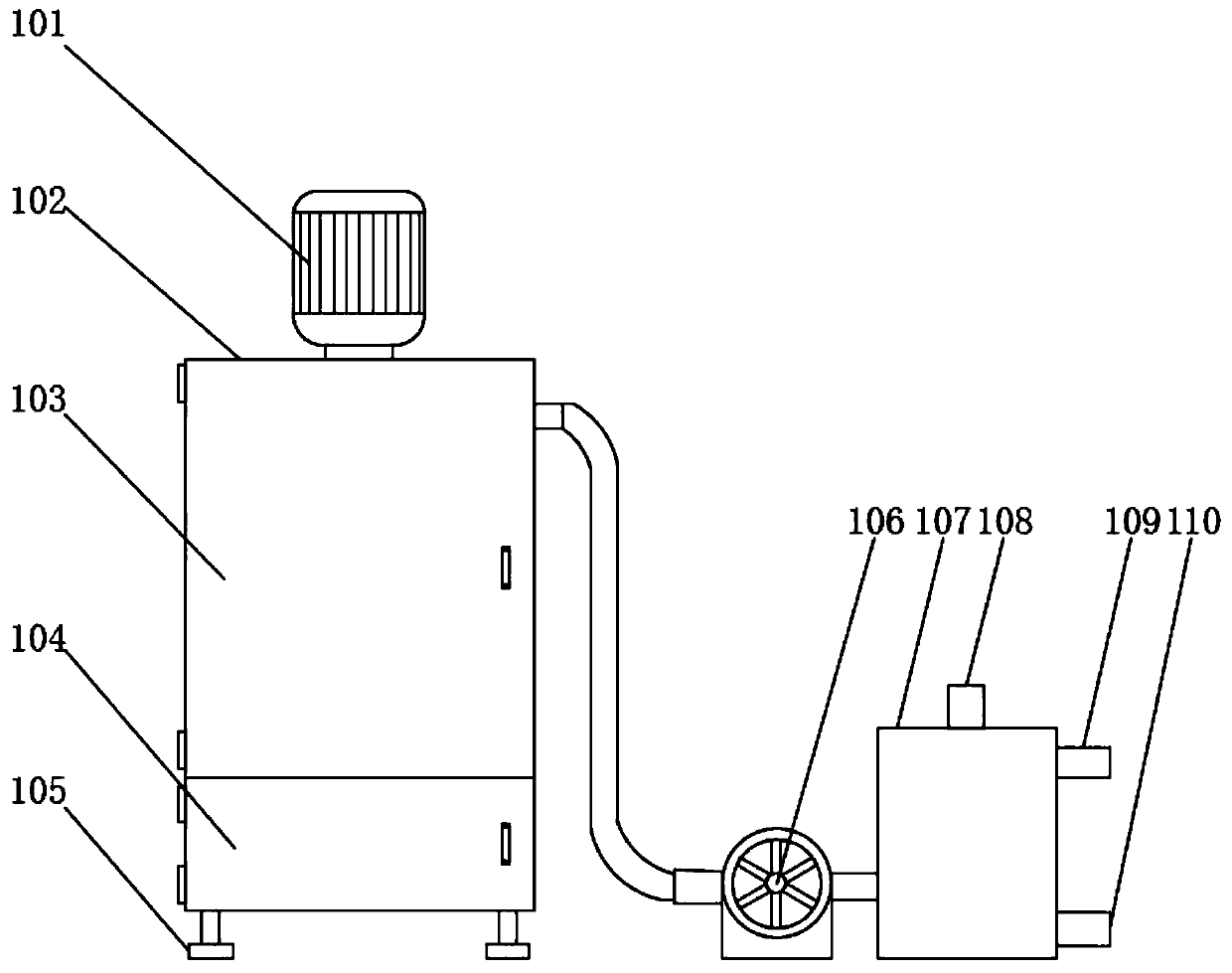

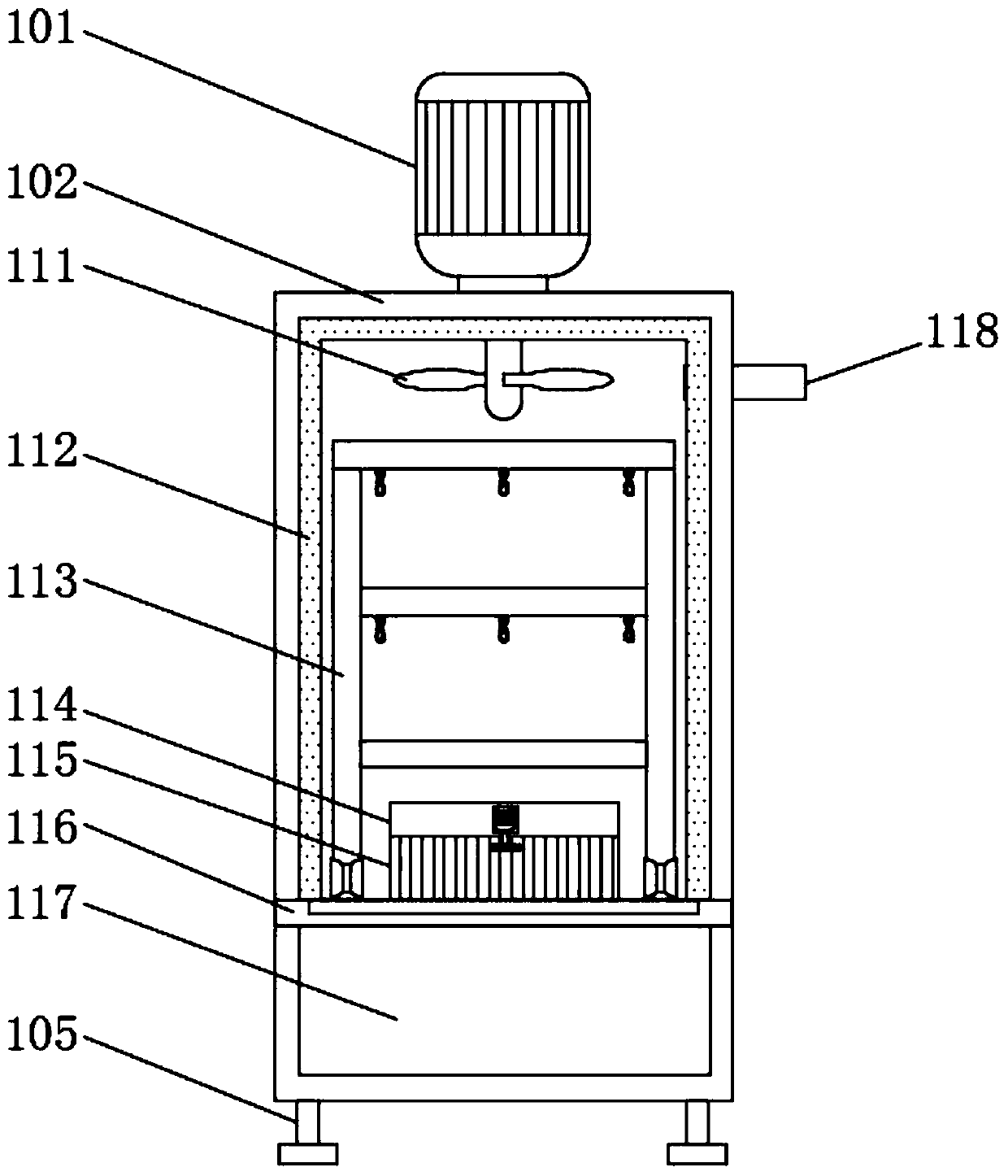

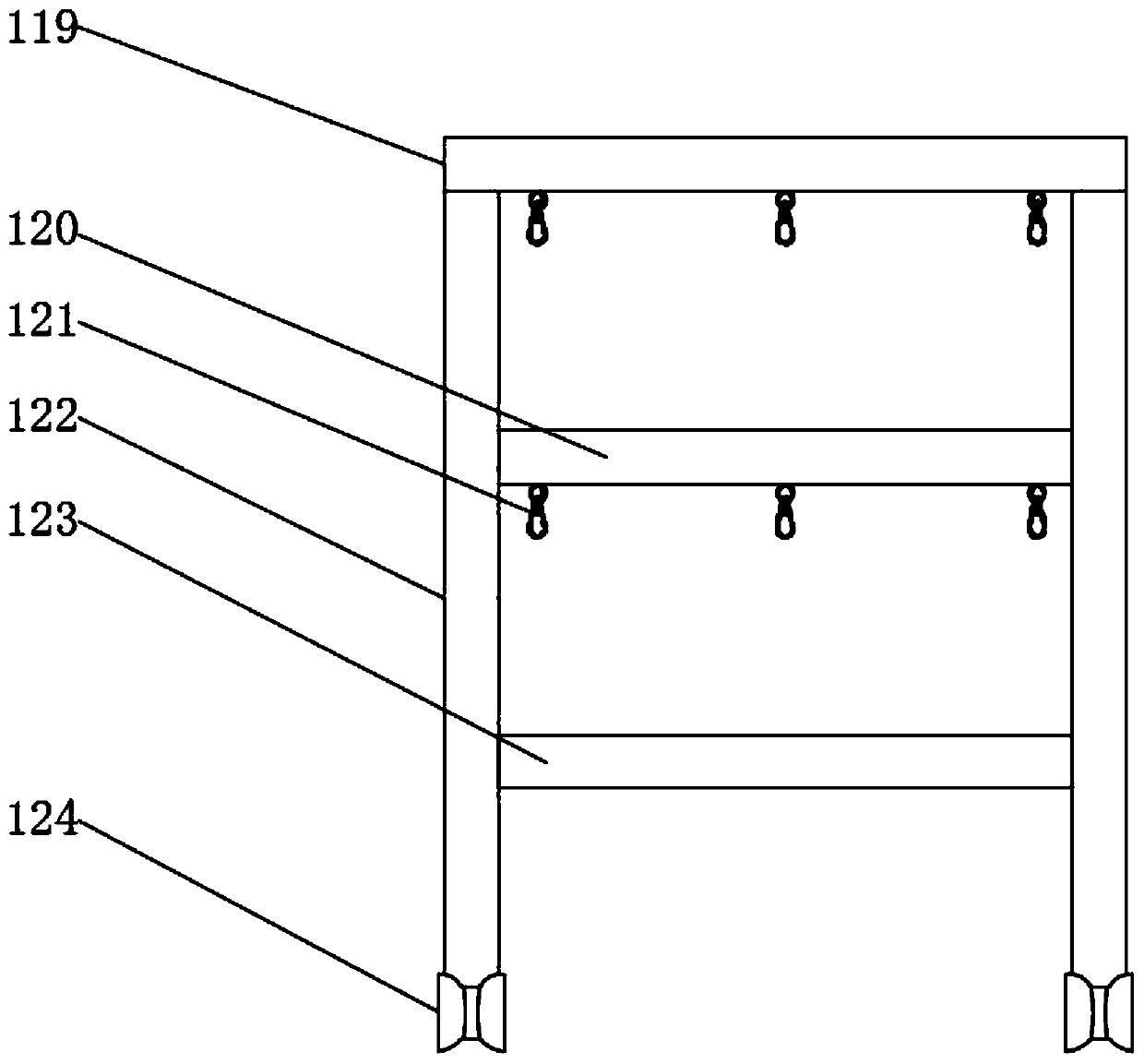

[0061] see Figure 1-11 As shown, this embodiment is a method for preparing cured pork belly based on smoked and roasted pork belly, which includes the following components in parts by weight: 100 parts of pork belly, 20 parts of ingredient 1, 5 parts of ingredient 2 share;

[0062] Ingredients 1 includes the following components in parts by weight: 80 parts of edible salt, 20 parts of Chinese prickly ash, 22 parts of pepper, 5 parts of star anise, 5 parts of tea polyphenols, 10 parts of sodium erythorbate, and 100 parts of cooking wine;

[0063] The second ingredient includes the following components in parts by weight: 35 parts of star anise, 30 parts of lotus leaf powder, 12 parts of cloves, 4 parts of Schisandra chinensis, 7 parts of fragrant leaves and 480 parts of cooking wine;

[0064] The smoked and roasted cured pork belly is prepared by the following steps:

[0065] Step 1: Raw material preparation:

[0066] Weigh the pork belly, wash it with flame singeing, cut i...

Embodiment 2

[0089] see Figure 1-11 As shown, this embodiment is a method for preparing cured pork belly based on smoked and roasted pork belly. The smoked and roasted cured pork belly includes the following components in parts by weight: 100 parts of pork belly, 22 parts of ingredient 1, and 8 parts of ingredient 2 share;

[0090] Ingredients 1 includes the following components in parts by weight: 90 parts of edible salt, 23 parts of Chinese prickly ash, 25 parts of pepper, 5 parts of star anise, 7 parts of tea polyphenols, 15 parts of sodium erythorbate, and 110 parts of cooking wine;

[0091] The second ingredient includes the following components in parts by weight: 37 parts of star anise, 35 parts of lotus leaf powder, 13 parts of clove, 6 parts of schisandra, 7 parts of bay leaf and 500 parts of cooking wine;

[0092] The smoked and roasted cured pork belly is prepared by the following steps:

[0093] Step 1: Raw material preparation:

[0094] Weigh the pork belly, wash it with fla...

Embodiment 3

[0117] see Figure 1-11 As shown, this embodiment is a method for preparing cured pork belly based on smoked and roasted pork belly. The smoked and roasted cured pork belly includes the following components in parts by weight: 100 parts of pork belly, 25 parts of ingredient one, and 10 parts of ingredient two share;

[0118] Ingredients 1 includes the following components in parts by weight: 100 parts of edible salt, 25 parts of Chinese prickly ash, 28 parts of pepper, 6 parts of star anise, 10 parts of tea polyphenols, 20 parts of sodium erythorbate, and 120 parts of cooking wine;

[0119] The second ingredient includes the following components in parts by weight: 40 parts of star anise, 40 parts of lotus leaf powder, 13 parts of cloves, 8 parts of Schisandra chinensis, 8 parts of fragrant leaves and 520 parts of cooking wine;

[0120] The smoked and roasted cured pork belly is prepared by the following steps:

[0121] Step 1: Raw material preparation:

[0122] Weigh the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com