Polypropylene composite material with high impact resistance and high bearing capacity and preparation method and application thereof

A composite material, polypropylene technology, applied in the field of polymer composite materials, can solve the problem of high usage of matrix resin, and achieve the effects of reducing usage, high performance indicators, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The preparation method of the high-impact, high-load-bearing polypropylene composite material described in embodiment one may further comprise the steps:

[0034] Step 1, using a silane coupling agent to carry out surface modification treatment on the filler and the reinforcing fiber, the surface modification method of the modified filler is: adding the silane coupling agent diluted with absolute ethanol to the talcum powder , the amount of silane coupling agent added is 0.8% to 1% of the mass of talcum powder, the mass ratio of absolute ethanol to silane coupling agent is 9:1, stir and mix evenly in a high-speed mixer, and the mixing time is 10 minutes; the modified The surface modification method of the reinforced fiber is as follows: add the silane coupling agent diluted with absolute ethanol to the wollastonite fiber, the amount of the silane coupling agent added is 0.8-1% of the wollastonite fiber mass, anhydrous The mass ratio of ethanol to silane coupling agent i...

Embodiment 6

[0039] Embodiment 6, mechanical performance test.

[0040] A. Tensile property test, carry out tensile property test to the composite material of embodiment 1 to embodiment 5, take single polypropylene material as control group, first composite material and control group are prepared into according to GB / T1040.2-2006 standard For standard splines, the pulling rate is set to 50mm / min. The tensile performance test of the composite material was carried out on a computer-controlled universal tensile testing machine. The tensile strength and elongation at break of the composite material could be obtained from the test. The results are shown in Table 4.

[0041] The composite material of table 4 embodiment one to embodiment five and the tensile strength (MPa) of control group

[0042]

[0043]Referring to Table 4, according to the average value of the tensile strength measurement data, it can be seen that in the composite materials prepared by adding different wollastonite fiber...

Embodiment 8

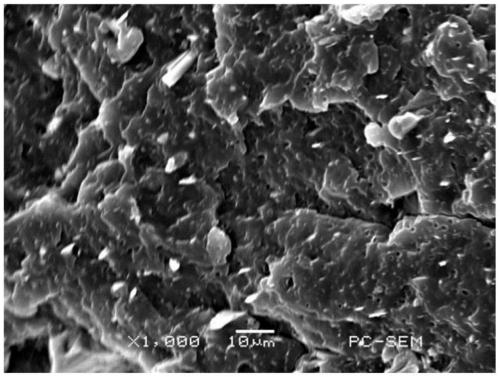

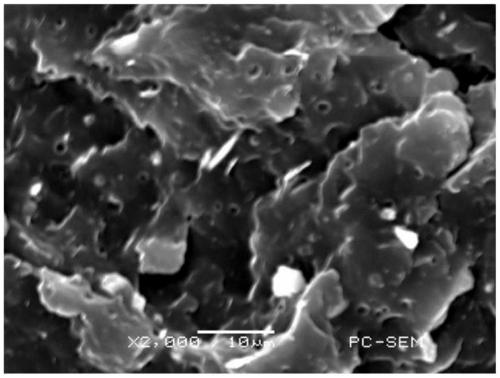

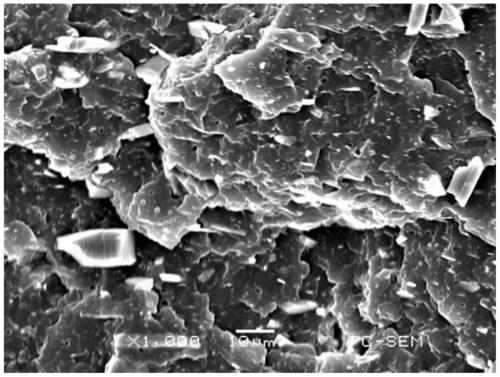

[0053] Embodiment 8, the composite materials of Embodiment 2 and Embodiment 3 were analyzed by scanning electron microscope respectively.

[0054] The cold and brittle section obtained by breaking the composite materials of Example 2 and Example 3 after cooling with liquid nitrogen, observed the structure and morphology of the section under the JSM-6460LV scanning electron microscope of JEOL Ltd., and the morphological structure presented in the microscopic The difference between the filler and the dispersion state of the filler in the polypropylene resin, because each part of the composite material is not conductive, so before putting it into the scanning electron microscope for observation, the sample should be gold-plated first, so that the composite material The surface is conductive, and then the cross-section of the composite material is scanned under an electron microscope to obtain SEM images of the composite material under different formulations. For the results, see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com