A Segmented Electromagnetic Coupled Separator for Treating Oilfield Produced Fluid

A technology of electromagnetic coupling and production of liquid, which is applied in the direction of electric separation of liquid, separation method, electric/magnetic dehydration/demulsification, etc., which can solve the problems of roughness, low separation efficiency, and easy electrical breakdown.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0045] The functional effects of the present invention are specifically described below through examples.

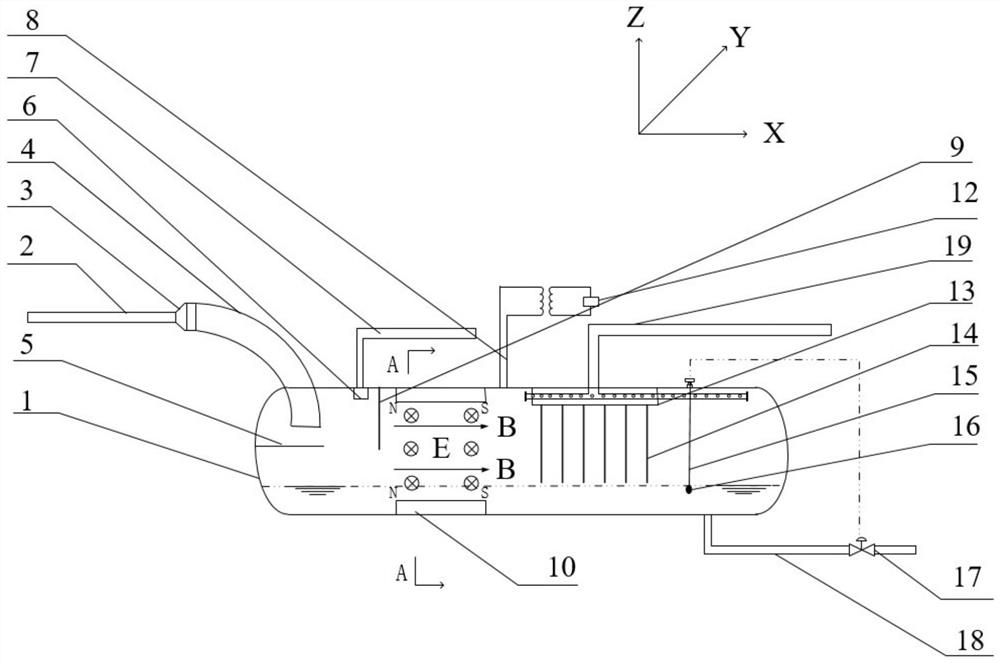

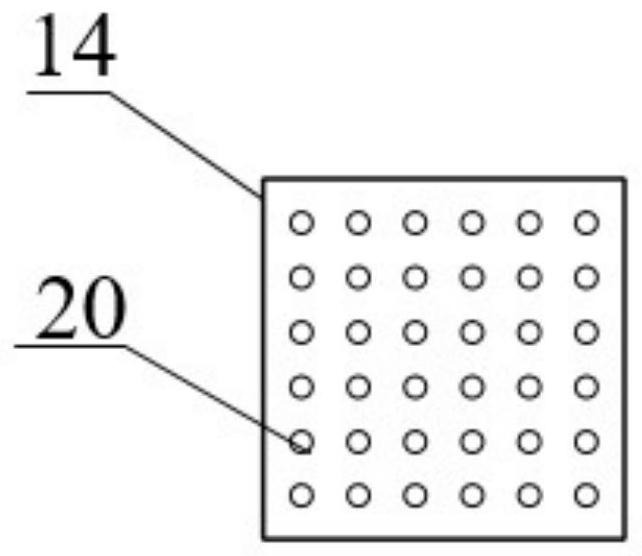

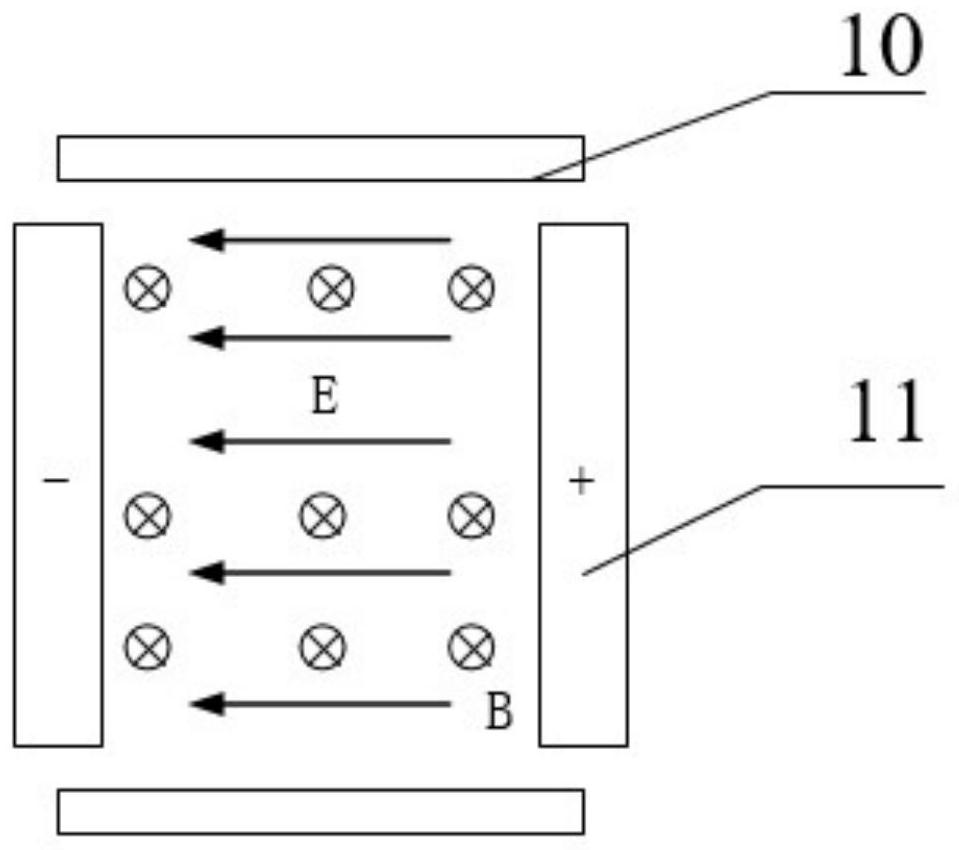

[0046] Such as figure 1 As shown, a segmented electromagnetic coupling separator for processing oilfield produced fluid, including a separator main body, a gas-liquid separation module, a high water content electromagnetic synergy dehydration module, a low water content electric dehydration module, a power supply system, and a liquid level controller , gas outlet, oil collection pipe and water outlet.

[0047] The separator tank body 1 is placed horizontally, and the upper part of one end is provided with an oil-gas-water inlet pipe. The oil-gas-water inlet pipe is composed of a horizontal straight pipe 2, a diameter-expanding pipe 3 and a downwardly inclined pipe 4, wherein the horizontal straight pipe 2 The cross-section is circular, the expansion angle of the expanding pipe 3 is between 10°~20°, the downturning angle of the downturning pipe 4 is between 25°~30°, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com