Hollow structure biomass activated carbon fiber and preparation method thereof

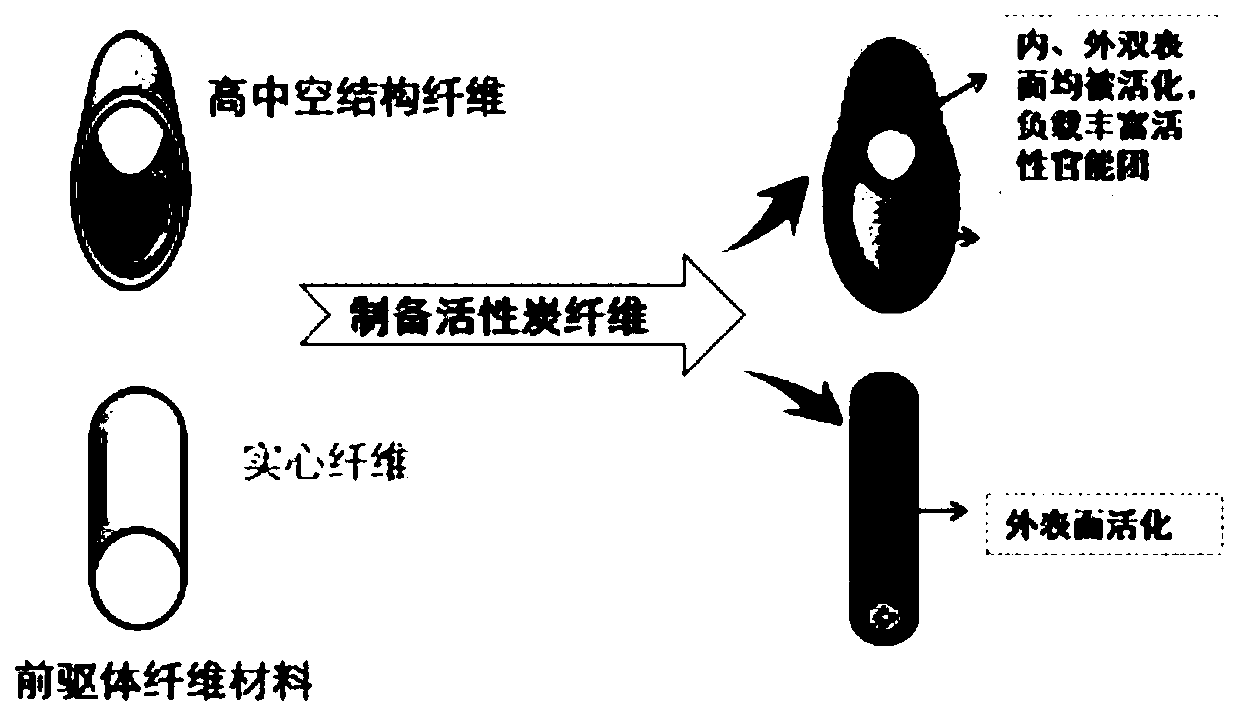

A technology of activated carbon fiber and biomass fiber, applied in the direction of fiber chemical characteristics, chemical instruments and methods, water pollutants, etc., can solve the problems of unsuitable environmental development, low specific surface area, affecting the application of carbon fiber, etc., and achieve excellent surface reaction performance , The effect of increasing the specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

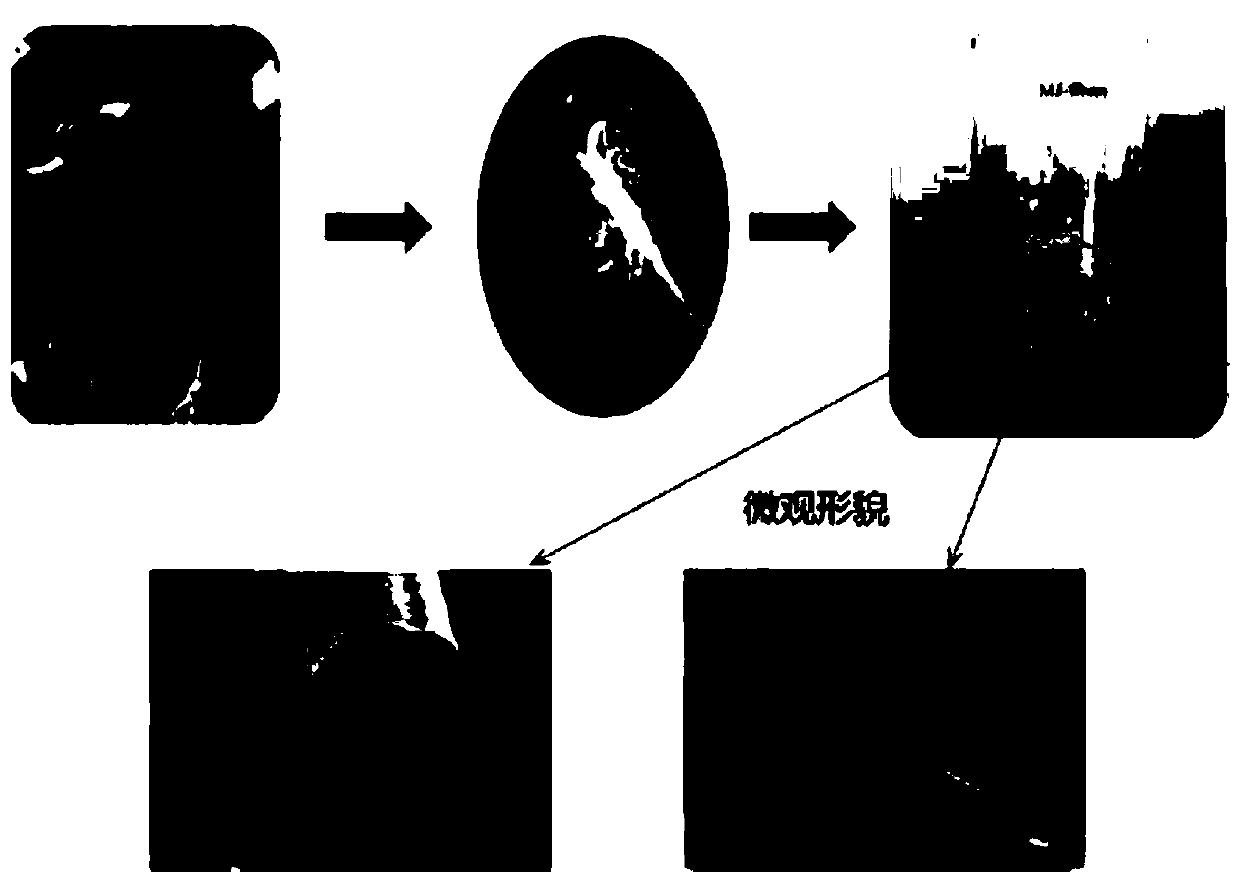

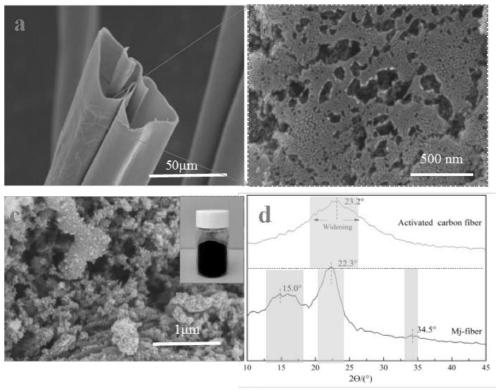

Method used

Image

Examples

Embodiment Construction

[0032] For the following, through the description of the examples, the specific implementation of the present invention, such as the manufacturing process involved, the operation and use method, etc., will be described in further detail, so as to help those skilled in the art to have a more complete concept of the invention and the technical solution of the present invention. , accurate and in-depth understanding.

[0033] Radish is a perennial herbaceous vine. Its roots, fruit shells, stems, leaves, and seeds can be used in traditional Chinese medicine. It is a characteristic Chinese medicinal material resource in Anhui Province and is now widely planted. The seed hair fiber of radish is derived from the villi of the seed, which is a companion organism. Each plant of radish can produce 320-650g seed fiber, which is abundant and easy to collect. The fiber has the characteristics of light weight, high bulkiness, and biodegradability. Contains medicinal active ingredients, has n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com