Method for preparing polypeptide complex by combining tea polyphenol and polypeptide

A technology of polypeptide complex and tea polyphenols, which is applied in the protein composition, application, and food science of vegetable seeds, and can solve problems such as waste, sedimentation and discarding, and research obstacles of insoluble matter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

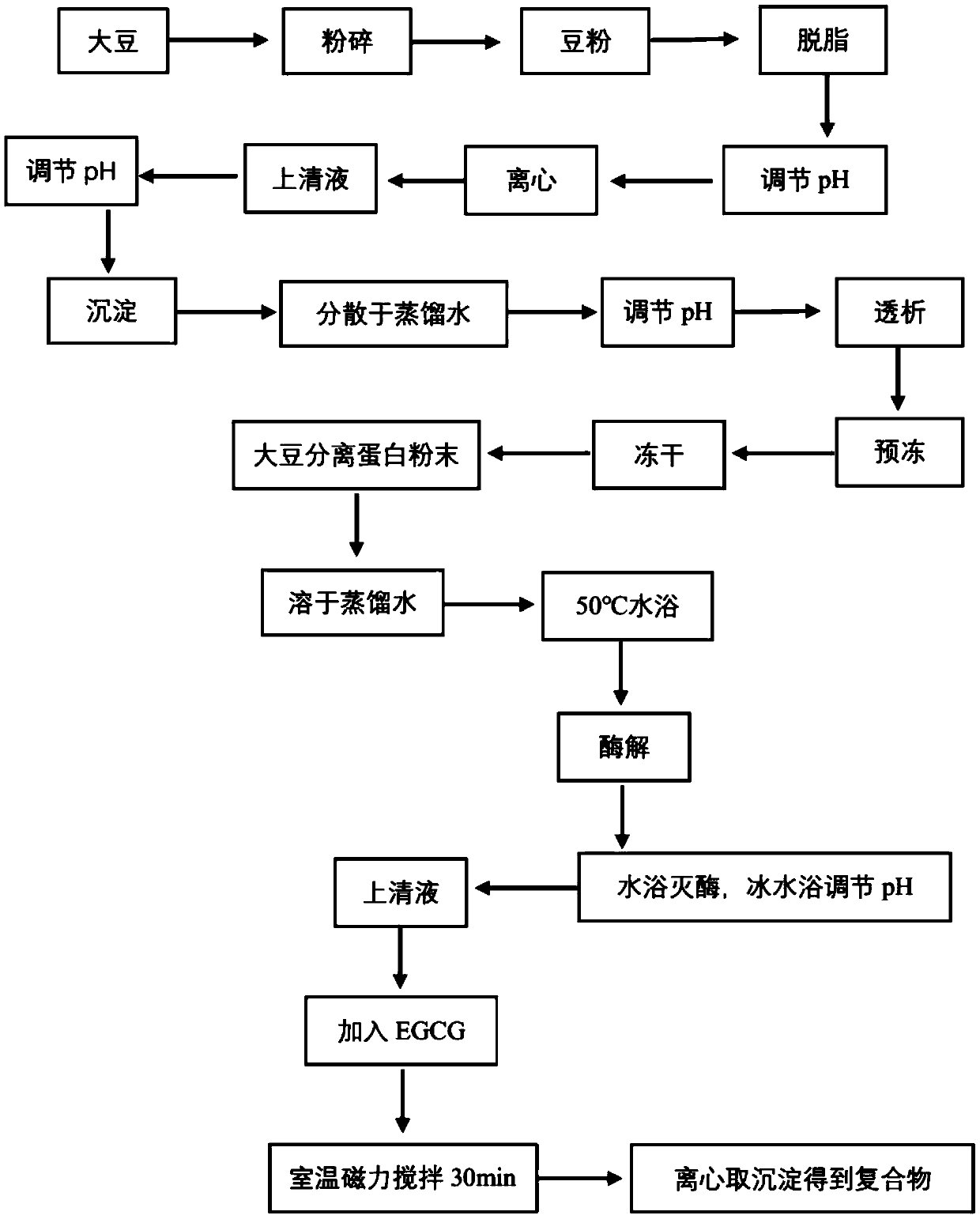

Method used

Image

Examples

Embodiment 1

[0014] According to the ratio of 1:3 (w / v), the soybean flour obtained after crushing was degreased three times with n-hexane, and placed in a fume hood to remove n-hexane, and the soybean powder from which n-hexane was removed was 1:8 (w / v) w) Dissolve in distilled water, adjust the pH to 8.5 with 2M NaOH, and mechanically stir the resulting slurry at 44 °C for 2 h, maintaining the pH at 8.5. Then centrifuge at 9000g for 20min, collect the supernatant and adjust the pH to 4.5 with 2M HCl, then centrifuge at 6000g for 20min, dissolve the obtained precipitate in distilled water, neutralize to pH 7.0 with 2M NaOH, and wash with Dialyze with distilled water for 24 hours, then pre-freeze at -40°C, freeze-dry, and grind to obtain soybean protein isolate powder; (2) Weigh soybean protein isolate powder and dissolve it in deionized water to prepare a 3% (w / v) soybean protein isolate solution , stirred mechanically at 50° C. for 2 h to make the soybean protein structure more loose, an...

Embodiment 2

[0016] According to the ratio of 1:3 (w / v), the soybean powder obtained after crushing was degreased three times with n-hexane, and placed in a fume hood to remove n-hexane, and the soybean powder from which n-hexane was removed was 1:10 (w / v). w) Dissolve in distilled water, adjust the pH to 8.5 with 2M NaOH, and mechanically stir the resulting slurry at 45 °C for 2 h, maintaining the pH at 8.5. Then centrifuge at 9000g for 20min, collect the supernatant and adjust the pH to 4.5 with 2M HCl, then centrifuge at 6000g for 20min, dissolve the obtained precipitate in distilled water, neutralize to pH 7.0 with 2M NaOH, and wash with Dialyze with distilled water for 24 hours, then pre-freeze at -40°C, freeze-dry, and grind to obtain soybean protein isolate powder; (2) Weigh soybean protein isolate powder and dissolve it in deionized water to prepare a 4% (w / v) soybean protein isolate solution , stirred mechanically at 50° C. for 2 h to make the soybean protein structure more loose,...

Embodiment 3

[0018] According to the ratio of 1:3 (w / v), the soybean flour obtained after crushing was degreased three times with n-hexane, and placed in a fume hood to remove n-hexane, and the soybean powder from which n-hexane was removed was 1:12 (w / v). w) Dissolve in distilled water, adjust the pH to 8.5 with 2M NaOH, and mechanically stir the resulting slurry at 46 °C for 2 h, maintaining the pH at 8.5. Then centrifuge at 9000g for 20min, collect the supernatant and adjust the pH to 4.5 with 2M HCl, then centrifuge at 6000g for 20min, dissolve the obtained precipitate in distilled water, neutralize to pH 7.0 with 2M NaOH, and wash with Dialyze with distilled water for 24 hours, then pre-freeze at -40°C, freeze-dry, and grind to obtain soybean protein isolate powder; (2) Weigh soybean protein isolate powder and dissolve it in deionized water to prepare a 5% (w / v) soybean protein isolate solution , stirred mechanically at 50° C. for 2 h to make the soybean protein structure more loose, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com