LED Bin dividing method and application product thereof

A product and standard technology, applied in the field of LED product application, can solve problems such as random selection of color coordinate range, insufficient research, different color saturation or color purity, etc., to achieve simple and convenient implementation, excellent light and color consistency, Good color consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

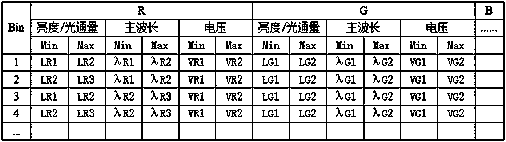

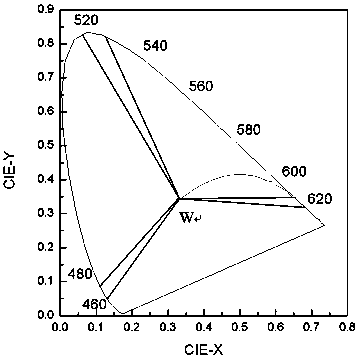

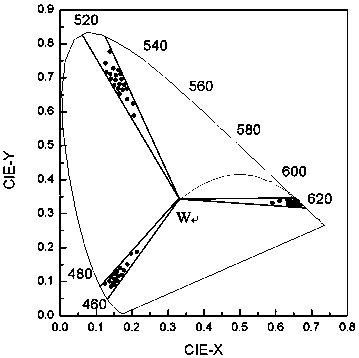

[0045] Such as Figure 4 As shown, it is used to illustrate a kind of LED binning method involved in the present invention and a flow diagram of its application products. In this embodiment, the bin objects are selected as LED full-color packaging products, and the specific models are surface mount 1010 / 1515 / 2727 / 3535, etc., and the RGB main wavelength interval span is defined as 4nm (maximum value-minimum value), and the brightness interval span is 1:1.2 (minimum value: maximum value / minimum value), the voltage interval span is 0.6V (maximum value-minimum value), and the color purity interval span is 15% (maximum value-minimum value).

[0046] Randomly select a certain amount of packaged samples to be binned, and the number of samples to be tested shall not be less than 10% of the total product. Test the main wavelength, brightness, voltage, and color coordinates of the product under the RGB binning current (20-20-20mA) respectively, and Do statistical analysis on the first ...

Embodiment 2

[0062] Referring to Example 1, in addition to those described in Example 1, the parameters in the LED bin standard may or may not include parameters such as leakage current, power, peak wavelength, half-wave width, color rendering index, and color temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com