Preparation method of heating pipe for water radiating pipe detection device

A heating tube and tube detection technology, used in applications, tubular items, household appliances, etc., can solve problems such as uneven temperature in local areas, and achieve the effects of reducing heat loss, improving bonding fastness, and reducing bubble rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

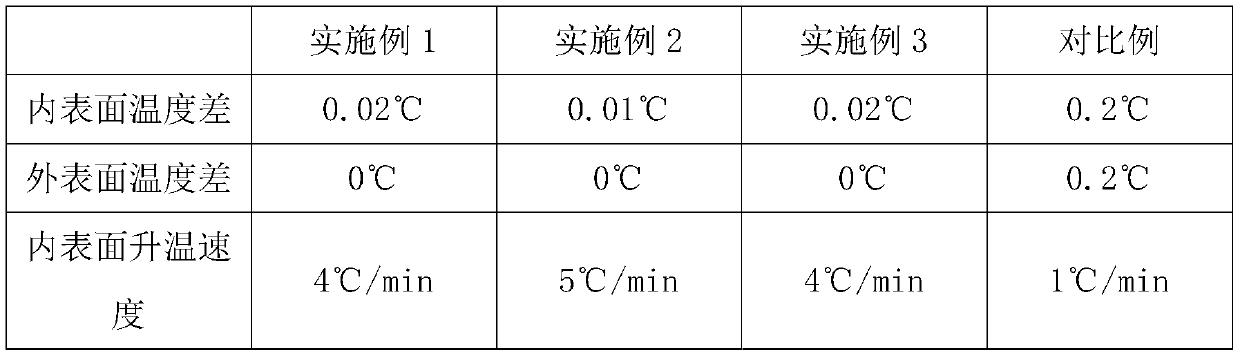

Examples

Embodiment 1

[0024] A method for preparing a heating pipe for a water heat pipe detection device, comprising the steps of:

[0025] Step 1, uniformly spray acid solution on the inner surface of the metal steel pipe, rinse and dry to obtain a roughened steel pipe;

[0026] Step 2, adding the phenolic resin to absolute ethanol and stirring evenly to form a viscous liquid to obtain a phenolic resin viscous liquid;

[0027] Step 3, evenly coating the phenolic resin viscous liquid on the rough surface of the steel pipe, and then extruding the phenolic foam board on the rough surface at a constant temperature to obtain a heat-insulating coated steel pipe;

[0028] Step 4, adding aluminum oxide to the phenolic resin viscous liquid in step 2 and ultrasonically dispersing to obtain a suspended mucus;

[0029] Step 5: spread the graphene fiber net on the inner surface of the steel pipe, and then coat the suspended mucus on the surface of the graphene fiber net, press and react at a constant tempera...

Embodiment 2

[0037] A method for preparing a heating pipe for a water heat pipe detection device, comprising the steps of:

[0038] Step 1, uniformly spray acid solution on the inner surface of the metal steel pipe, rinse and dry to obtain a roughened steel pipe;

[0039] Step 2, adding the phenolic resin to absolute ethanol and stirring evenly to form a viscous liquid to obtain a phenolic resin viscous liquid;

[0040] Step 3, evenly coating the phenolic resin viscous liquid on the rough surface of the steel pipe, and then extruding the phenolic foam board on the rough surface at a constant temperature to obtain a heat-insulating coated steel pipe;

[0041] Step 4, adding aluminum oxide to the phenolic resin viscous liquid in step 2 and ultrasonically dispersing to obtain a suspended mucus;

[0042] Step 5, laying the graphene fiber net on the inner surface of the steel pipe, and then coating the suspended mucus on the surface of the graphene fiber net, extruding at a constant temperatur...

Embodiment 3

[0050] A method for preparing a heating pipe for a water heat pipe detection device, comprising the steps of:

[0051] Step 1, uniformly spray acid solution on the inner surface of the metal steel pipe, rinse and dry to obtain a roughened steel pipe;

[0052] Step 2, adding the phenolic resin to absolute ethanol and stirring evenly to form a viscous liquid to obtain a phenolic resin viscous liquid;

[0053] Step 3, evenly coating the phenolic resin viscous liquid on the rough surface of the steel pipe, and then extruding the phenolic foam board on the rough surface at a constant temperature to obtain a heat-insulating coated steel pipe;

[0054] Step 4, adding aluminum oxide to the phenolic resin viscous liquid in step 2 and ultrasonically dispersing to obtain a suspended mucus;

[0055] Step 5: spread the graphene fiber net on the inner surface of the steel pipe, and then coat the suspended mucus on the surface of the graphene fiber net, press and react at a constant tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com