Method for preparing sintered pellets from low-grade phosphorite and waste of phosphorus chemical industry

A low-grade, phosphorus chemical technology, applied in the direction of chemical instruments and methods, phosphorus compounds, phosphate material treatment, etc., can solve the problem that phosphorus slag acid cannot be directly used, and achieve large batch processing capacity and less binder consumption , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

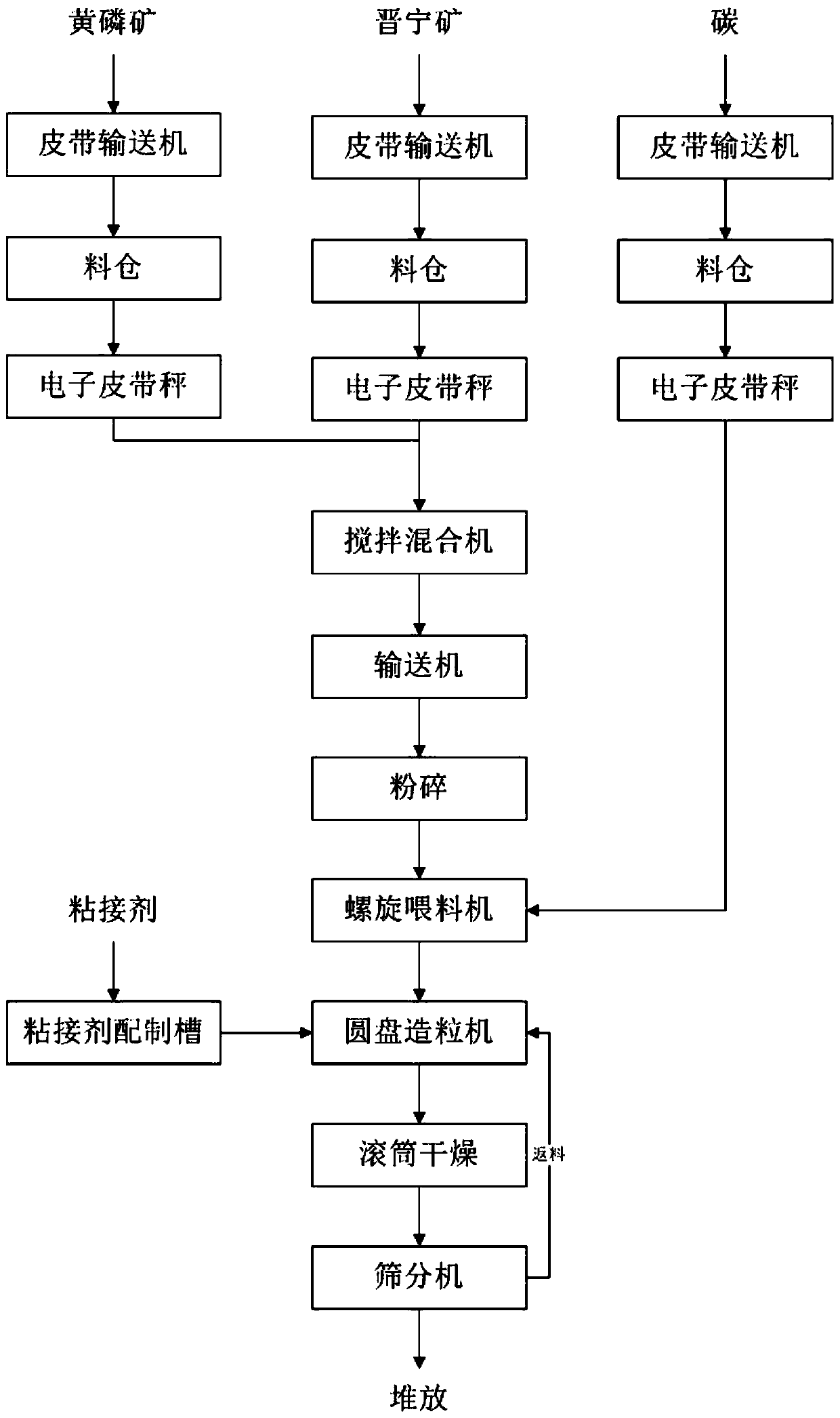

Method used

Image

Examples

Embodiment 1

[0042] Raw materials: yellow phosphorus sieved ore, yellow phosphorus sieved charcoal, collection location: Yunnan Jinning Yellow Phosphorus Co., Ltd.; low-grade phosphate rock, phosphoric acid slag acid, collection location: Yunnan Phosphate Group Co., Ltd.

[0043]The main chemical composition of yellow phosphorus under-screen ore in this example is shown in Table 1:

[0044] Table 1

[0045]

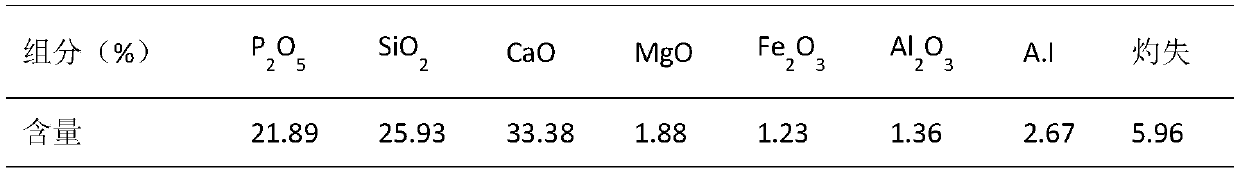

[0046] The main chemical composition of low-grade phosphate rock in this example is shown in Table 2:

[0047] Table 2

[0048]

[0049] In this example, the main chemical composition of the charcoal under the sieve of yellow phosphorus is shown in Table 3:

[0050] table 3

[0051]

[0052] The main chemical composition of phosphoric acid slag acid is shown in Table 4 in this example:

[0053] Table 4

[0054]

Embodiment approach

[0056] The yellow phosphorus sieved ore, low-grade phosphate rock and yellow phosphorus sieved charcoal are mixed according to the mass ratio of 45:55:15 with an electronic scale; %), to obtain the powdery material; the powdery material is added to the binder phosphorous slag acid (P 2 o 5 concentration of 35%) into a disc granulator to granulate to a particle size of 20-50mm (the sieve residue is less than 5%) to obtain mixed pellets; put the mixed pellets into the rotary kiln and use yellow phosphorus tail gas as a heat source , and dried at 200° C. for 15 minutes to obtain dry pellets; the dry pellets are put into the furnace together with conventional yellow phosphorus charge (phosphorite, silica, coke) to prepare yellow phosphorus.

[0057] In this example, pellet composition analysis is shown in Table 5:

[0058] table 5

[0059]

[0060]

[0061] In this example, the experimental results are shown in Table 6:

[0062] Table 6

[0063]

[0064] It can be se...

Embodiment 2

[0066] Raw materials: yellow phosphorus sieved ore, yellow phosphorus sieved charcoal, collection location: Yunnan Pingbian Yellow Phosphorus Factory; low-grade phosphate rock, phosphoric acid slag acid, collection location: Yunnan Phosphate Group Co., Ltd.

[0067] In this example, the main chemical composition of the yellow phosphorus under-screen ore is shown in Table 7:

[0068] Table 7

[0069]

[0070] The main chemical composition of low-grade phosphate rock in this example is shown in Table 8:

[0071] Table 8

[0072]

[0073] In this example, the main chemical composition of the charcoal under the sieve of yellow phosphorus is shown in Table 9:

[0074] Table 9

[0075]

[0076] The main chemical composition of phosphoric acid slag acid is shown in Table 10 in this example:

[0077] Table 10

[0078]

[0079] method of execution:

[0080] The yellow phosphorus sieve ore, low-grade phosphate rock and yellow phosphorus sieve charcoal are mixed accordi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com