Manufacturing method of long life lane paint containing nanoceramic incorporated

A nano-ceramic and driveway technology, applied in the direction of cement coating, coating, etc., can solve the problems of increased budget and high price, and achieve the effects of improving wear resistance, simplifying on-site construction, and ensuring heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

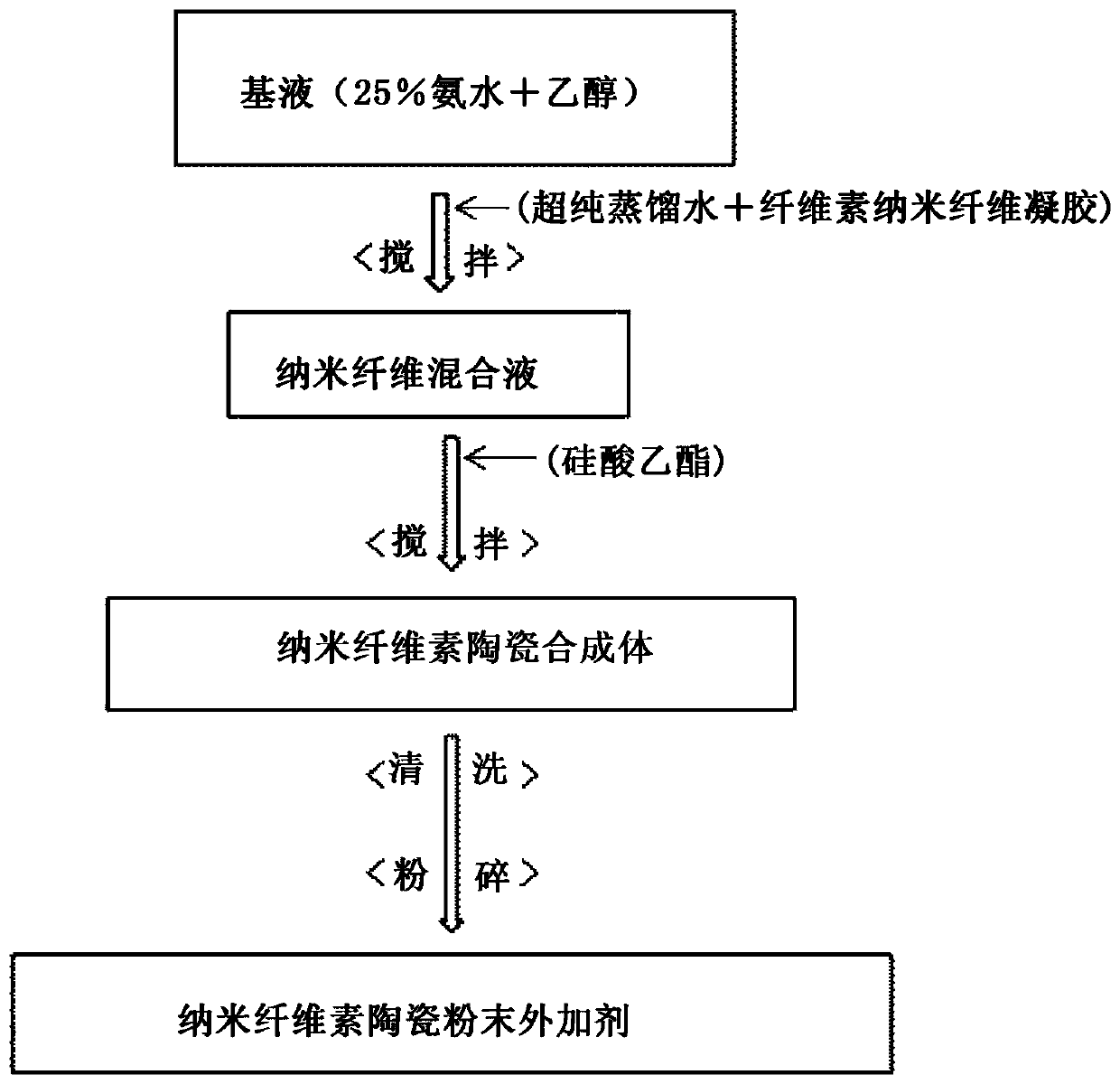

Method used

Image

Examples

no. 1 example

[0057] In the experimental example, in a) step, the base liquid was prepared by mixing 19.6 ml of 25% ammonia water and 147.6 ml of ethanol, and in b) step, 1.44 ml of ultrapure distilled water, 2.16 ml of distilled water were added to the above base liquid. g of cellulose nanofiber gel, and prepare the nanofiber mixture by stirring, in c) step, mix 11.2ml of ethyl silicate in the above nanofiber mixture and prepare by stirring nanocellulose ceramic composites.

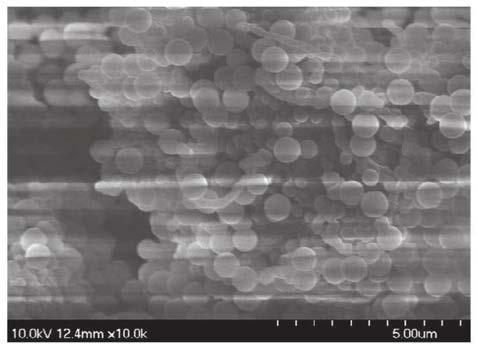

[0058] In each of the above processes, cellulose nanofibers prepared by dispersing 3.7% of cellulose nanofibers with a diameter of 50 to 100 nm in 96.3% of ultra-pure distilled water were used as the cellulose nanofiber gel added in step b). gel. Meanwhile, the stirrer used in step b) and step c) used a small electronic device, and the stirring speed was fixed at 400 rpm to uniformly disperse through the fast stirring speed. That is, the agitation in step b) was performed at 400 rpm for 10 minutes to fully disperse ...

no. 2 example

[0065] In the second experimental example, the cellulose nanofiber gel added in step b) was slightly increased from 2.16 g in the first experimental example to 3.6327 g, and the remaining components of the reagents remained the same.

[0066] That is, in a) step, the base liquid is prepared by mixing 19.6 ml of 25% ammonia water and 147.6 ml of ethanol, and in b) step, 1.44 ml of ultra-pure distilled water, 3.6327 g of fiber A plain nanofiber gel was prepared by stirring to prepare a nanofiber mixture. In step c), 11.2 ml of ethyl silicate was mixed into the above nanofiber mixture and stirred to prepare nanofibers grown with silica Plain ceramic composite.

[0067] image 3 It is a scanning electron microscope analysis photo of the cellulose ceramic composite according to the second experimental example. As mentioned above, even if the mixing amount of cellulose nanofiber gel is increased, the amount of cellulose nanofibers is still more than the amount of silica particles ...

no. 3 example

[0069] From the first experimental example and the second experimental example, it can be seen that the amount of cellulose nanofibers needs to be further increased. In the third experimental example, the cellulose nanofiber gel added in step b) is greatly increased. In order to adjust the amount of silica particle size, while increasing the amount of ultrapure distilled water.

[0070] That is, in the third experimental example, in the same manner as the first experimental example and the second experimental example, 19.6 ml of 25% ammonia water, 147.6 ml of ethanol, and 11.2 ml of ethyl silicate were kept, respectively. The ultrapure distilled water and cellulose nanofiber gel were changed to 10.8ml and 18.1636g, and a nanocellulose ceramic composite body with silica grown was prepared by the same procedure as above.

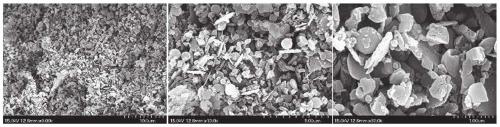

[0071] As a result, such as Figure 4 As shown, it can be seen that the cellulose nanofibers grown with silica are connected to each other, but the size of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com