Coulter with bionic cladding layer on surface and preparation method of coulter

A cladding layer and coulter technology, which is applied to coulters with bionic cladding layers on the surface and the field of preparation thereof, can solve the problems of shortened service life of coulters, difficult to guarantee machining accuracy, large coulter wear and the like, and achieves the service life of the coulters Extend, improve wear resistance and corrosion resistance, and reduce farming resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0068] The present application also provides a method for preparing a coulter whose surface has a bionic cladding layer according to any one of the above, wherein the method for preparing the moldboard comprises the following steps in sequence:

[0069] 1) Substrate surface pretreatment: pretreat the substrate of the moldboard, to remove dust, grease and oxide film adhering to the outer surface of the substrate of the moldboard;

[0070] 2) Grinding and polishing: first use sandpaper to grind the outer surface of the base body of the moldboard, and then polish the outer surface of the base body of the moldboard to a mirror state with a diamond abrasive paste with a particle size of 1.0 μm;

[0071] 3) Cleaning: including substrate cleaning and vacuum chamber cleaning, first the substrate of the moldboard is ultrasonically cleaned to wash away the residual dirt on the outer surface of the substrate of the moldboard;

[0072] Clean the vacuum chamber with argon until the oxygen ...

Embodiment 1

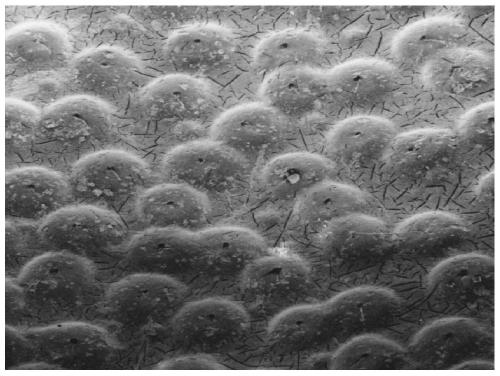

[0095] A coulter with a bionic cladding layer on its surface, comprising a coulter, a bionic cladding layer is arranged on the outer surface of the base body of the coulter, and the bionic cladding layer is a convex hull type bionic cladding layer 102; A plurality of convex hulls 1021 are arranged on the soil-touching outer surface (the outer surface in contact with the soil) of the convex-hull biomimetic cladding layer 102;

[0096] The biomimetic cladding layer includes the following components in mass percentage: C: 4.2%, B: 1.8%, Si: 2.2%, Cr: 26.5%, Ni: 4.5%, W: 2.6%, Co: 1.8%, Mo : 4.2%, Fe: balance;

[0097] A coulter with a biomimetic cladding layer on the surface described in Example 1 further includes a ploughshare, and an iron-based cladding layer 201 is provided on the outer surface of the base body of the plowshare;

[0098] The iron-based cladding layer 201 includes the following components in mass percentage: C: 4.2%, B: 1.6%, Si: 2.6%, Cr: 28.2%, Ni: 5.2%, W: ...

Embodiment 2

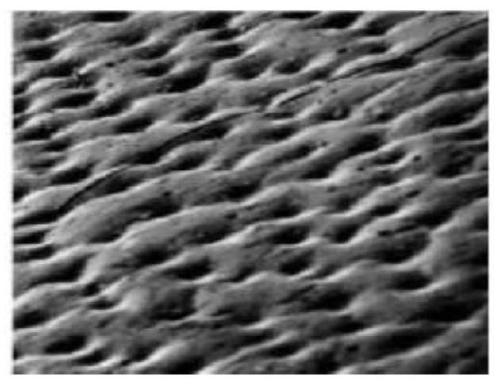

[0125] A coulter with a bionic cladding layer on its surface, comprising a coulter, a bionic cladding layer is provided on the outer surface of the base body of the coulter, and the bionic cladding layer is a pit-shaped bionic cladding layer 101; A plurality of pits 1011 are arranged on the soil-touching outer surface (the outer surface in contact with the soil) of the pit-type bionic cladding layer 101;

[0126] The biomimetic cladding layer includes the following components in mass percentage: C: 4.3%, B: 2.1%, Si: 2.6%, Cr: 26.5%, Ni: 4.5%, W: 2.6%, Co: 2.2%, Mo : 3.9%, Fe: balance;

[0127] A coulter with a biomimetic cladding layer on the surface described in Example 2 also includes a plowshare, and an iron-based cladding layer 201 is provided on the outer surface of the base body of the plowshare;

[0128] The iron-based cladding layer 201 includes the following components in mass percentage: C: 4.2%, B: 2.3%, Si: 2.7%, Cr: 28.2%, Ni: 5.2%, W: 2.6%, Co: 2.1% , Mo: 4.1%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com