Structurally ordered chitosan/nanocellulose composite aerogel and preparation method thereof

A nanocellulose and composite aerogel technology, applied in aerogel preparation, chemical instruments and methods, colloid chemistry, etc., can solve the problems of poor mechanical properties, brittleness of aerogels, etc. The effect of excellent thermal properties, excellent mechanical and thermal insulation properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

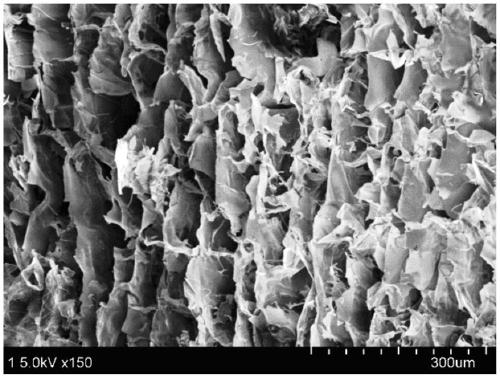

[0027] (1) 2g chitosan powder is dissolved in concentration and is 2% acetic acid solution, in the oil bath of 60 ℃, magnetic force stirs 60min, obtains the chitosan solution that concentration is 2%; The dialdehyde solution was aged for 20 hours to obtain chitosan hydrogel, which was washed with distilled water to neutrality; the hydrogel was oriented frozen in liquid nitrogen at a freezing rate of 10mm / min, and then the completely frozen solidified block was frozen at -50 ℃ freeze-drying for 48 hours to obtain long-range ordered chitosan airgel;

[0028] (2) Place the chitosan airgel in (1) in a nanocellulose dispersion with a concentration of 0.5%, freeze in a refrigerator for 24 hours, and freeze-dry at -50°C for 24 hours to obtain a shell with an ordered structure Polysaccharide / nanocellulose airgel.

Embodiment 2

[0030] (1) 1g chitosan powder is dissolved in the concentration of 2% acetic acid solution, in the oil bath of 60 ℃, magnetically stirred for 60min to obtain a concentration of chitosan solution of 1%; The dialdehyde solution was aged for 12 hours to obtain chitosan hydrogel, which was washed with distilled water until neutral; the hydrogel was oriented frozen in liquid nitrogen at a freezing rate of 5mm / min, and then the completely frozen solidified block was frozen at -50 ℃ freeze-drying for 48 hours to obtain long-range ordered chitosan airgel;

[0031] (2) Place the chitosan airgel in (1) in a nanocellulose dispersion with a concentration of 0.8%, freeze in a refrigerator for 24 hours, and freeze-dry at -50°C for 24 hours to obtain a shell with an ordered structure Polysaccharide / nanocellulose airgel.

Embodiment 3

[0033] (1) 1.5g chitosan powder is dissolved in concentration and is the acetic acid solution of 1.5%, in the oil bath of 60 ℃, magnetic force stirs 60min, obtains the chitosan solution that concentration is 2%; Add concentration is 1% Glutaraldehyde solution was aged for 24h to obtain chitosan hydrogel, which was washed with distilled water to neutrality; the hydrogel was oriented frozen in liquid nitrogen at a freezing rate of 10mm / min, and then the completely frozen solidified block was placed in- Freeze-drying at 50°C for 48 hours to obtain long-range ordered chitosan airgel;

[0034] (2) Place the chitosan airgel in (1) in a nanocellulose dispersion with a concentration of 1%, freeze in a refrigerator for 24 hours, and freeze-dry at -50°C for 24 hours to obtain a shell with an ordered structure Polysaccharide / nanocellulose airgel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com